What are you looking for?

15. July 2013

The Kaizen System

The Kaizen system is a Japanese management system that provides for a continuous improvement process across all areas of the company through the participation of all employees. Literally translated Kai means "change, transformation" and Zen "for the…

15. July 2013

Kanban system

The Kanban system is a planning system for production control. the Kanban system is often split into material flow and replenishment are controlled starting from the processing location, based on the goods used here. Since it is not possible to act…

15. July 2013

Definition – Automated Storage and Retrieval System

An "Automated Storage and Retrieval System" (short: AS/RS, sometimes also "Automated small parts warehouse") is a storage system in which small-volume units such as screws or electronic parts are stored. These Systems are always automated, in…

15. July 2013

Rack zones – bending zone

A rack can be divided into vertical zones based on the scale of an adult (average size of 1.70 m). The lowest rack area is called the bending zone. It reaches an average height of 60 - 80 cm. In the bending zone, goods with low turnover are often…

15. July 2013

Rack zones – gripping zone

A rack can be divided into vertical zones based on the scale of an adult (average size of 1.70 m). The gripping zone starts at an average height of 60 - 80 cm and reaches up to a height of 1.40 - 1.60 m. Employees can reach the gripping zone without…

15. July 2013

Rack zones – viewing zone

A rack can be divided into vertical rack based on the scale of an adult (average size of 1.70 m). The viewing zone starts at an average height of 1.40 - 1.60 m and reaches up to 1.80 m depending on the height. The viewing zone is the storage area at…

15. July 2013

Cross-docking

There are different types of handling goods in the shipping area. One of these is called cross-docking and is a form of cross-connection. The most striking characteristic of this type of transhipment is that cross-docking does not involve storage.…

15. July 2013

Just-in-time – Definition

“Just-in-time” refers to a type of delivery in which the required goods are delivered on time and in exact quantities in order to keep warehousing at the processing location as low as possible. The decisive difference to just-in-sequence…

15. July 2013

Procurement logistics – Just in sequence

"Just in sequence" refers to a type of delivery in which the required goods are delivered to the right place at the right time, in the right quantity and of the right kind and processed immediately. The decisive difference to "just-in-time"…

15. July 2013

Overview of person-to-goods picking

Person-to-goods picking (also: man-to-goods picking) describes a picking method in which the provision of the inventory takes place statically. In other words, the employee goes to the storage location and takes the required inventory on the spot.…

15. July 2013

Overview of goods-to-person picking

Goods-to-person picking (also: goods-to-man picking) describes a picking method in which the provision of inventory is dynamic and automated. In this process, articles are fed directly to the picker by means of materials handling technology. The…

15. July 2013

Single-stage order picking – order-oriented, serial picking

With order-oriented, serial picking, order items are successively processed according to orders. Either an order picker passes through all warehouse zones or an order is transferred from an order picker of a certain zone to the next order picker and…

12. July 2013

Sorter (Packing) – Process steps

The process steps that are carried out in the course of the (sorter) packing process include order picking dispatching, batch picking, batch buffer reservation, batch buffer and packing process sorter packing. The goals of the packing department are…

12. July 2013

Sorter – Packaging

Definition of Packing The packaging is the merging of storage units to form a complete unit. In the fields of production and technology, the term "packing" refers to the division or length division of units. It is also often used as a synonym for…

12. July 2013

Enterprise Resource Planning System (ERP System)

As an application program, an enterprise resource planning system (ERP system) supports all task areas and processes of a company, such as procurement, production, sales, accounting and human resources. With the use of standard application software…

12. July 2013

Production data acquisition

Operating data is data from organisational and technical areas of a company. This includes order data and personnel data on the one hand and machine data and process data on the other. The accumulation of this data is called operating data…

12. July 2013

Overview of application interfaces (APIs)

Interfaces have the task of connecting IT systems with the environment, i.e. other facilities, disciplines or subsystems. In the field ofprogrammable logic controllers (PLCs), the connection between the PLC and the environment is often established…

10. July 2013

Inventory management

Inventory management refers to the administration, planning and control of material flows within a company or between companies, customers, suppliers or branch offices. On the one hand, it records the movement of goods and, on the other hand,…

10. July 2013

Definition of intralogistics

The term intralogistics was created in 2004 by the "Forum Intralogistics" of the VDMA (German Engineering Federation). Since the term "logistics" is generally associated with the transport industry and freight transport, an equivalent was sought to…

10. July 2013

The basics of warehouse planning – Determining the objectives

In the past, when planning a warehouse, the main focus was often exclusively on the resulting costs and their minimization. Today, the planning and realization of a warehouse are viewed more holistically in order to ensure lasting profitability…

10. July 2013

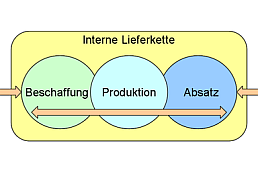

The importance of material flow

According to VDI, "material flow" is the interlinking of all processes involved in extracting, processing and distributing goods within defined areas. Material flow includes all forms of the passage of work objects (e.g. materials, parts, data…

9. July 2013

Transport management – The material flow computer

The material flow computer calculates the fastest route through the materials handling equipment in real-time as part of the transport management process. Taking into account the available facility resources, the material flow computer decides on…

9. July 2013

The manual sort order fulfilment

Manual Sort Order Fulfilment (MSF) is a software-supported, manual sorting system. The basis is a multi-stage picking process, but compared to the use of an automated sorter, the subsequent sorting work is done by humans. The MSF is responsible for…

5. July 2013

Single-stage picking without IT system support

Picking without IT system support requires a manageable assortment of articles, which is clearly structured according to product groups. Within a product group, storage by ascending article number ensures fast access. The entire stock of an item is…

24. June 2013

Storage location management – The importance of EDP in warehouse organization

In modern warehouses with a certain amount of goods, the warehouse processes are usually computerized. Computer-aided warehouse organization enables more effective and economical processes. For example, by using a storage bin management system, it…

24. June 2013

The evolution of warehouse management

Warehouse management has undergone a tremendous development from its beginnings until today. Whereas manual processes were once laboriously structured via analog media, today both the technology and the process view have fundamentally evolved The…

24. June 2013

Definition of business processes

Business processes can be used to visualize business-relevant procedures of a company. A task that arises through business activities is partitioned into business processes. This in turn results in a fragmentation into sub-processes, whereupon the…

24. June 2013

Definition – Contract logistics

Logistics includes all tasks for planning, controlling, providing and optimizing processes along the value chain. Contract logistics is a business segment of logistics services. It is geared towards long-term cooperation between manufacturers and…

24. June 2013

Function of a laser scanner

An precisely focused and finely bundled laser beam is used as a light source for the laser scanner's reading system. The laser beam is deflected by a rotating polygon mirror, creating an upandlandy laser beam. This is forwarded to the barcode…

24. June 2013

Functionality of a CCD Camera

CCD stands for Charge-coupled Device. Within a CCD camera, light-sensitive elements (CCD sensors) are mounted in the focal point of a lens system. The fast, parallel-serial scanning of the individual points (pixels) resolves a bar code to a point…

6. June 2014

FEM 9.831 Calculation basis for stacker cranes for high-bay warehouses

FEM 9.831 is a standard for the use of stacker cranes in high-bay warehouses. The standard…

5. May 2014

Distance selling contract

A distance contract is a contract concluded between an entrepreneur and a consumer by means of…

24. April 2014

Definition of Same Day Delivery

Same Day Delivery means that inventory is delivered on the same day it was ordered. Ordered today,…

19. March 2014

Master data

In intralogistics, master data, also known as primary data or reference data, is data that contains…

11. March 2014

VDI 3601 – Warehouse Management Systems

In Guideline 3601 - "Warehouse Management Systems", the Association of German Engineers (VDI)…

24. February 2014

Batch formation in picking

Batch formation during picking, also known as batch picking or multi-order picking, is a form of…

3. February 2014

Storage and retrieval machine

A storage and retrieval machine (SRM) is a storage device with which load units can be stored,…

24. January 2014

The beginnings of logistics

Even before the invention of the wheel, materials were transported, handled and stored. Even then,…

20. December 2013

Definition – Value chain

A value chain describes how value is created through a chain of activities and combined in…

10. December 2013

Sorter (Packing) – Basics

After the picking business process, the product is passed on to the sorter (packing department).…

6. December 2013

Lean Management

Lean management also has several sub-categories, such as lean thinking, lean production and lean…

4. December 2013

Single-stage picking – basics

During picking, a certain quantity of articles is picked from an assortment and put together.…

3. December 2013

Definition – Transshipment logistics

Goods handling is a function of intralogistics and takes place between the external goods flow and…

21. November 2013

Picking – definition and picking methods

Picking stands for the assembly of goods and merchandise according to specified orders from an…

14. November 2013

Overview of common manufacturing principles

Different principles can be applied in manufacturing. Some products are manufactured according to…

12. November 2013

Push system and pull system in supply chains

Supply chain management refers to the value chain from the supplier to the end consumer. Depending…

30. September 2013

Modernization: retrofit in intralogistics

Term retrofit refers to the modernization of machines and equipment. It includes the terms…

25. September 2013

Material throughput time

The material throughput time is the time required to run through all business processes, for…

20. September 2013

Time strategies: throughput and delivery time reduction

Besides the just-in-time and just-in-sequence methods, other time strategies can be used to ensure…

17. September 2013

Mobile and stationary loading units

Loading units are collections of goods that are transported, transhipped or stored as they pass…

16. September 2013

Potential analysis in intralogistics

A potential analysis is a comparison of company performance with the given expectations for said…

16. September 2013

Performance analysis in logistics

A performance analysis examines various service points in logistics for their contribution to value…

9. September 2013

Transport strategies: Overview

Transport strategies are used to execute existing transport orders. Transportation strategies can…

3. September 2013

Continuous conveyor / discontinuous conveyor

Both the continuous conveyor and the discontinuous conveyor belong to the conveyor technology…

30. August 2013

Overview of linear sorter systems

The linear sorter, or shoe sorter, is an automated sorting and distribution system on which the…

Also available in Deutsch (German)