Artificial Intelligence (AI) can be defined as intelligence that originates exclusively from machines, robots and cyber-physical systems. The research area AI tries to understand, emulate and mimic human perception and action. According to the field of AI research, these are systems that approximate, imitate, replicate, automate or even surpass and improve human thinking.

Arthur Samuel, one of the pioneers of machine learning, defined machine learning as a field of study that gives computers the ability to learn without being explicitly programmed. At that time he was sure that computers had the ability to learn specific tasks without being explicitly programmed. What was then still a theory due to the lack of experience is now, thanks to the sub-areas of AI namely machine learning and deep learning, substantially advanced.

The focus of AI research is however not a single, uniform technology. Rather, they are interrelated technological elements (software and hardware) which can be used in many different ways and are dependent on the problem at hand. Roughly put, it can be said that artificial intelligence consists of perceptual, processing and learning elements.

General fields of application for AI

There are numerous examples of practical application in enterprises [1]

- Examination and assessment (sample classification): credit check, insolvency check, image recognition

- Clustering: market segmentation, data mining

- Forecast (Prediction): price forecasts, sales forecasts, cost forecasts

- Optimization: transport optimization (Travelling-Salesman-Problem), sequence planning

AI and its subdomain Machine Learning

To be precise, Machine Learning (ML) has little to do with artificial intelligence in the true sense of the word. Instead, ML focuses on pattern recognition, which can be done by machines or computers. ML is the easiest and cheapest way to give computers a base form of ‘artificial’ intelligence. Based on large amounts of data, so-called training data, and algorithms, training phases are coordinated which, coupled with the use of the processed data, lead to the software being able to modify itself or to acquire new capabilities on its own. Classical examples of machine learning are the learning algorithms ‘Naive Bayes’ and ‘Collaborative Filtering’. The latter is known from the online platform Amazon and the phrase seen there ‘Customers who bought this article also bought’. Naive Bayes, on the other hand, are used in spam filters for e-mail management. The actual intelligence of machine learning systems is the ability to modify themselves – as soon as more informationor data is available. If high-quality data (see also Smart Data) are available to an ML system, human intervention can often be omitted.

AI and the subarea Deep Learning / Neural Networks

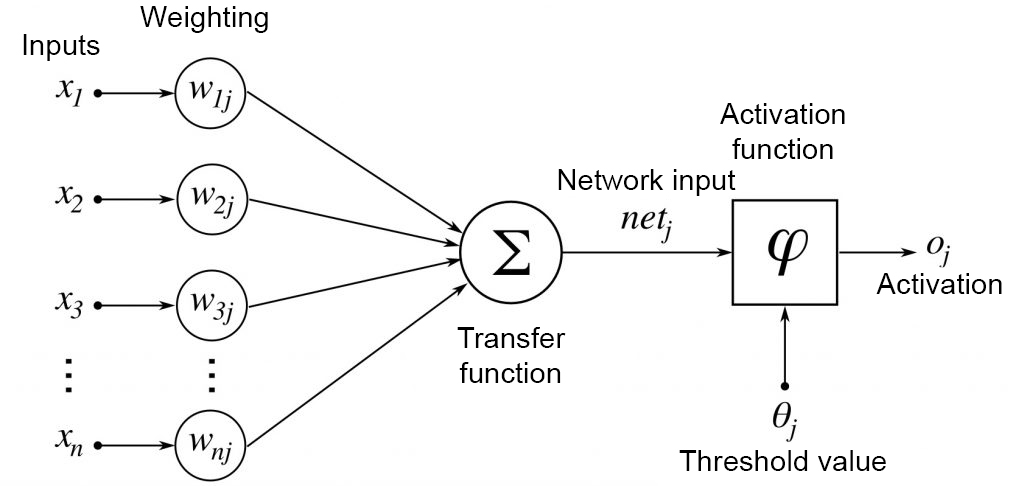

Deep Learning is a process based on artificial neural networks (ANN for short). In most applications, the algorithms of deep learning are based on the basic structure of the human brain, which is made up of large numbers of interconnected neurons. Like their human counterparts, the ANN computational models, or the algorithms used, learn from experience by individually adapting the simulated neuron connections.

Structure of a neural network

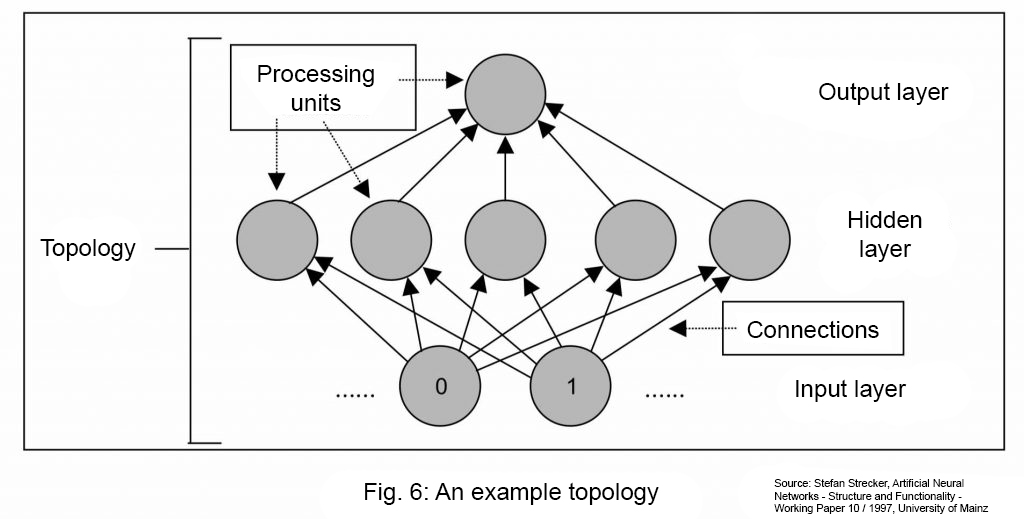

According to the Cluster for Artificial Intelligence (Bremen AI), “the neurons of an artificial neural network are arranged layer by layer and are usually interconnected in a fixed hierarchy. The neurons are usually connected between two layers (inter-neuron layer connection), but in rare cases also within a layer (intra-neuron layer connection)”.

Editor’s note: The effectiveness of a neural network lies within its networking. Thus, the above-mentioned layers or the individual layers are linked together by means of individual neurons – in other words, each neuron of one layer is always linked to all neurons of the next layer. Individual pieces of information flow into the input layer, which in turn passes on the information to intermediate layers (hidden layers); in the end, the interpreted data are passed on via the output layer – “where the output of one neuron is the input of the next”. If a neural network obtains new data, these connections are strengthened or reduced; likewise, each connection in a neural network can be adapted by attributing greater or lesser relevance to an attribute.

Artificial neural networks generally have so-called core components or basic building blocks, which can be found in all types of networks [2].

- Processing elements

- Connections between processing units

- the network topology

The dynamic core components listed below describe the information processing that takes place within the ANN. The processing intervals are divided into the following phases.

- Learning phase

- Processing phase

AI: Elements of perception

Artificial intelligence must be able to absorb information in order to be able to understand and perceive the world around it. Thus, AI must have the ability to process text, capture images and video, record sound, and also capture information about environmental conditions such as temperature, wind and moisture. In this context, the Internet of Things (IoT) plays an important role, as it is about collecting heterogeneous data from innumerable heterogeneous devices, drawing conclusions from it and learning from it; a task that today also poses great challenges to advanced data analytics tools. In short, IoT consists of what is collected (information and devices), how these things are connected, how data is collected, what can be learned from the data, and finally, what can be deduced from it.

In short, IoT consists of what is collected (information and devices), how these things are connected, how data is collected, what can be learned from the data, and finally, what can be deduced from it. The sensors can be a GPS, cameras, microphones and specialised solutions such as pressure probes in robotic systems.

AI: Elements of data processing and learning

AI systems usually receive the information to be processed in two different ways. An operator supervises the so-called labelling of the data and manually ensures that the respective computer is provided with the data. He or she sets up the corresponding algorithm rules to achieve a specific output result if this is not the case the process is described as unsupervised learning. The data records are fed into the system manually or automatically; the artificial intelligence, however, draws its own conclusions without feedback from the operators. In both cases, information is collected, combined and repeatedly refined with the help of mathematical tasks. Since the labelling of the data as well as the set of rules around the respective algorithm depends on human operators, this labor-intensive process is also the most expensive one. As a result, there is now a diversified industry that exclusively labels data for the training of computer programs.

Example for AI use-cases

Service chatbots

In the future, artificial intelligence is expected to replace humans wherever computer-aided service leads to the desired result for the customer faster and in a higher quality. Service chatbots, for example, facilitate the search for information for customers and carry out simple transactions via voice or chat interfaces. Machine learning algorithms scan a variety of products and technical documentation and automatically answer common questions. It should be noted that such systems focus exclusively on simple issues. “In the future, modern methods of Natural Language Processing, as well as frameworks and platforms, will facilitate chatbot development; creating capable bots will become a standard”, Rudolf Grötz, Senior Technical Engineer at Raiffeisen Bank International [3].

In the future, users will search less and less on websites for relevant information. Instead, they will simply ask the chatbot a question.

Rudolf Grötz – ix Magazin für professionelle Informationstechnik / 06/2018, page 50

AI and logistics/intralogistics

The application of artificial intelligence is particularly useful in the field of logistics or intralogistics, in almost all areas of the supply chain. In the logistics area of a company, as well as within the logistics chain of all companies involved, vast amounts of data accumulate every day, both structured and unstructured; artificial intelligence is perfectly suited for utilizing this information. In this way, AI can help to develop new methods and behaviours, by turning reactive processes into proactive ones and by creating concrete predictions rather than assumptions or rough estimates as a base for management decisions. Of course, it is also possible to concentrate only on existing processes. Manual, as well as already automated processes, can be optimized in terms of duration and efficiency. In addition, services don’t need to be standardized any langer, but instead can be personalized and thus made more customer-friendly.

One example shows how striking the advantages of artificial intelligence in intralogistics can be: In an average store, 7.5 per cent of all items are not available because manual ordering processes led to articles being out of stock. The error rate drops to five per cent when specialized AI give recommendations to a human dispatcher. If the possibility of human intervention is abandoned and artificial intelligence carries out the warehouse and logistics tasks completely autonomously, the error rate drops to 0.5 per cent.

Joachim Bengelsdorf / diyonline-Magazin[4]

Examples for the use Artificial Intelligence in logistics

Warehouse logistics is considered the first area of application for a large-scale deployment of artificial intelligence. Man spricht auch vom Learning Warehouse. There a large amount of information is already being analyzed by algorithms every day.

-

- This is based on the assumption that the AI is already able to predict the occurrence of certain events (viae-commerce, multi-channel, cross-channel) with approximate accuracy. For example, by analysing ordering behaviour in greater depth, reliable statements (and thus measures) can be made regarding future orders/orders, which in turn enables a faster shipping process The key here is that the processes within a warehouse are automated in such a way that the respective procedures, whether for example goods receipt, putaway, retrieval/transfer, picking, finishingand goods issue, are clearly defined in terms of time. This makes it possible to give reliable statements for other processes in the supply chain.

- Another common practice is the recognition of trend items at a certain point in time. If necessary, the employees in responsible positions can then adjust the product allocation in the warehouse in order, for example, to push for route optimization during order picking; similar to the principle of fast and slow movers.

- Pending maintenance or improvement potential in the material flow can also be identified in this way. This represents a significant step toward cognitive logistics. The latter is without doubt the key objective within the supply chain. With the right semantics, objects can not only be related in a machine-understandable way; employees and senior management can navigate in real-time from a pick (e.g. pick-by-device) to the order or to the original advice note in incoming goods to achieve relevant insights. Especially the semantic analysis of logistic processes is a distinctive method of information retrieval, which in principle allows the interpretation of key figures and delivers exact results thanks to the inclusion of domain knowledge (synonyms, similarities, ontologies and taxonomies). In the future, it is conceivable that intelligent systems will be able to make decisions based on predictive analytics completely without human intervention.

- Also worth mentioning: The optimization of the collaboration between humans and robots (human-machine interface) is also a practical application of artificial intelligence; in the sense that robots can learn from humans. Using virtual reality and 3D modulation, humans can automatically generate digital information, such as distinct hand movements with millimetre precision; to grip individual positions, which in turn improves the gripping of robots within order picking (pick-by-robot).

Artificial intelligence makes the warehouse of the future more dynamic, agile and responsive. The intelligent networking of machine, process and product information is a quantum leap for process optimization.

Tim Eick, Head SynQ Competence Center, Swisslog Logistics Automation

A summary of artificial intelligence

From tour optimization, inventory management to batch formation and the resulting synergy effects in order dispatching; Artificial Intelligence and its algorithms already support the warehouse employee by means of targeted process optimization (see also Control Center in Intralogistics). In future, cognitive systems will have the ability to learn to recognise patterns and derive recommendations for action from them – without being dependent on human cognitive capacity. For example by supporting the warehouse staff in making decisions or by informing them in advance of likely events.Sources:

[3] ix Magazin für professionelle Informationstechnik / 06/2018, page 50

[4] diyonline.de / AI als Chance für die Intralogistik

If you are interested in automation, please also read the articles Computer-integrated Manufacturing and Smart Factory.

Also available in Deutsch (German)

Editor's note: The effectiveness of a neural network lies within its networking. Thus, the above-mentioned layers or the individual layers are linked together by means of individual neurons - in other words, each neuron of one layer is always linked to all neurons of the next layer. Individual pieces of information flow into the input layer, which in turn passes on the information to intermediate layers (hidden layers); in the end, the interpreted data are passed on via the output layer - "where the output of one neuron is the input of the next". If a neural network obtains new data, these connections are strengthened or reduced; likewise, each connection in a neural network can be adapted by attributing greater or lesser relevance to an attribute.

Editor's note: The effectiveness of a neural network lies within its networking. Thus, the above-mentioned layers or the individual layers are linked together by means of individual neurons - in other words, each neuron of one layer is always linked to all neurons of the next layer. Individual pieces of information flow into the input layer, which in turn passes on the information to intermediate layers (hidden layers); in the end, the interpreted data are passed on via the output layer - "where the output of one neuron is the input of the next". If a neural network obtains new data, these connections are strengthened or reduced; likewise, each connection in a neural network can be adapted by attributing greater or lesser relevance to an attribute.

Artificial neural networks generally have so-called core components or basic building blocks, which can be found in all types of networks [2].

Artificial neural networks generally have so-called core components or basic building blocks, which can be found in all types of networks [2].