Replenishment is a fundamentally important process in today’s enterprise resource planning. With the best possible integration into the existing warehouse management, it contributes significantly to the efficiency of the material flow. Replenishment or stock replenishment is used to replenish warehouses or pick stations in picking zones (e.g. from buffer warehouses or from buffer storage areas). In this process, the supply of inventory can be triggered preemptively, as needed, or due to a shortage in the warehouse. To ensure optimal utilization of the flow of goods and the existing warehouse stock, replenishment is controlled by the warehouse management system (WMS).

In intralogistics, replenishment describes a business process that takes place before, during or after picking. This type of inventory replenishment ensures a perpetual supply of inventory within a storage area.

While this type of replenishment is intralogistic in nature, there is also replenishment from the outside when it comes to ensuring continuous inventory in warehouses of distribution centers or manufacturing plants through transportation logistics.

Supply – variants and procedures

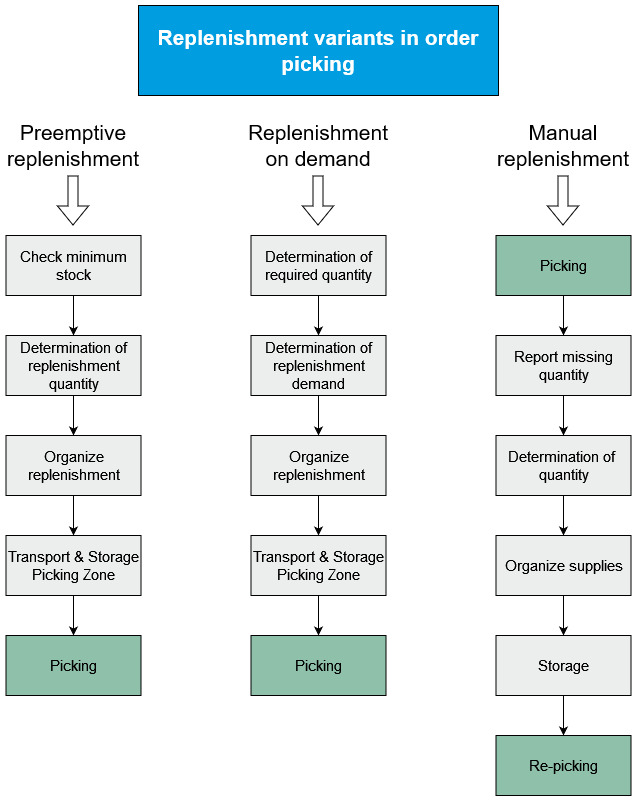

Replenishment of goods may be preemptive, on demand, or necessary due to a shortage in the warehouse. The different variants of replenishment can be combined depending on the warehouse layout; also to achieve an even system utilization with maximum readiness for delivery.

Depending on what triggers replenishment, there are various procedures, each of which depends on consumption, stock or time. The procedures are as follows and are based on the aforementioned trigger criteria:

- Replenishment procedure (consumption dependency) with the trigger criterion: consumption

- Reorder level procedure (stock dependency) with the trigger criterion: reaching the reorder level

- Cycle time procedure (time dependency) with the trigger criterion: MRP time

For each of the three procedures, the following options can take effect with regard to the replenishment quantity:

- Minimum replenishment quantity

- Optimum replenishment quantity

- Replenishment quantity to a target stock

Depending on the replenishment trigger criteria, combining them with the three replenishment options results in 9 different replenishment strategies.

A replenishment strategy should ensure, with minimal effort, a high availability of raw materials, semi-finished parts, materials and inventory in the respective warehouses and workstations. After all, the key function of replenishment is to prevent stock levels from falling below a defined minimum level, to avoid out-of-stocks and to ensure a smooth flow of materials; from the outside by transport logistics and from the inside by intralogistics.

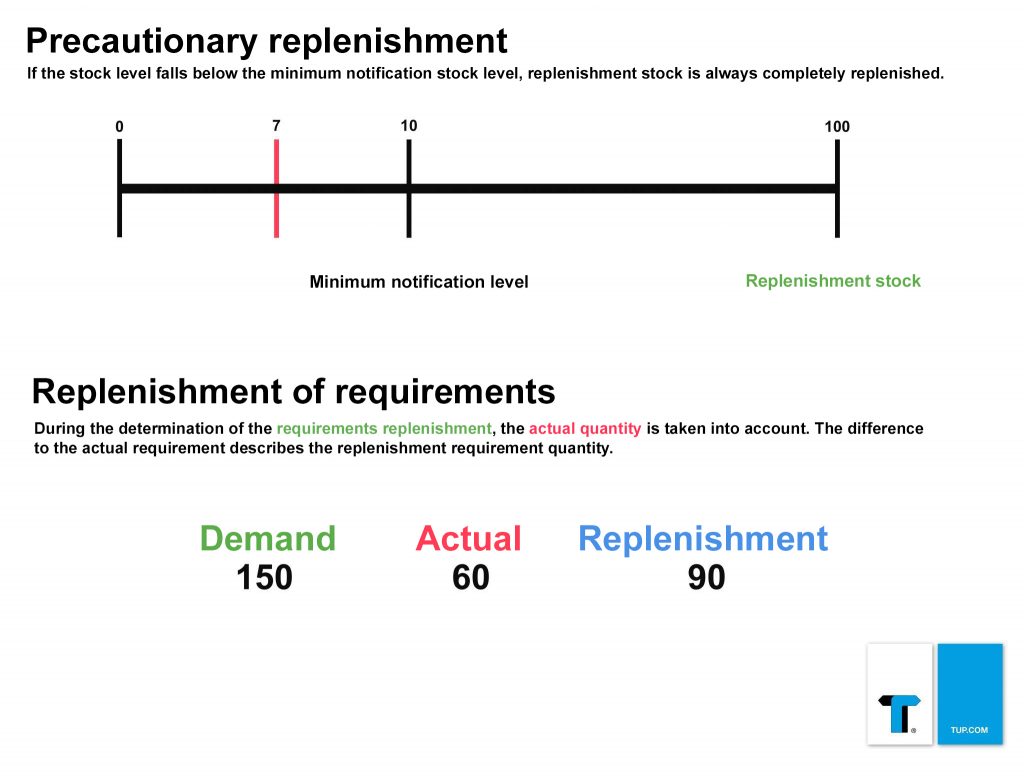

The following graphic illustrates a preemptive replenishment with a replenishment quantity to the target stock, as well as a demand replenishment with the minimum quantity that exactly covers the demand:

The individual replenishment procedures are described in more detail below:

Replenishment – Provisioning Procedure

Among the three replenishment methods, the staging method is especially suitable for self-regulating replenishment of the staging buffer of a consumption point, for example, an assembly line. Accordingly, the characteristic of this method is consumption dependence.

Basic principle of the staging process

In the pre-buffer area, a unit is waiting to be replenished to the next area. Replenishment to the next area takes place as soon as the contents therein are consumed. The storage unit then automatically moves up to a so-called staging area.

Two replenishment options

Consumption-based staging contains two replenishment options.

- One option concerns the replenishment of the buffer space. When a replenishment unit is delivered, a check is made to determine whether there is free storage space for additional units in the preliminary buffer area. Free buffer space is subsequently filled with units.

- The other option concerns the removal of storage units from the staging area. This checks whether the area still contains consumption units. If not, then replenishment is requested.

Advantages and disadvantages of the provisioning procedure

Compared with the reorder point procedure and the cycle time procedure, the advantage of the staging procedure is the self-regulating inventory, which is kept at a minimum level, and the short replenishment time. The disadvantage is the increased replenishment costs that arise when the replenishment quantity is set too low or material consumption increases very quickly.

Replenishment – reorder point procedure

The reorder point procedure has the characteristic of stock dependency. A reorder point is a stock quantity which, when reached, triggers a process that results in replenishment or a purchase order. As a sub-area of the ordering policy, it is also referred to as a reorder point system, which, from the perspective of warehousing/stock management, belongs to consumption-based material requirements planning and to consumption-based ordering procedures.

The reorder point ensures stock availability for production and trade and provides a guideline as to when replenishment or reordering is necessary. It is to be distinguished from the minimum stock level (safety stock level), which is intended to prevent production or delivery failures if, for example, a delivery arrives late or damaged.

Basic principle of the reorder point procedure

When a reorder point is received, the system checks whether the reorder point is undercut by this requirement posting.

The reorder point procedure contains two replenishment options in case the reorder point is reached or fallen short of.

- Order point-dependent individual replenishment: when the reorder level has been reached, an optimal replenishment quantity is ordered. The replenishment order of each article occurs independently of the replenishment needs of other articles.

- Order point-dependent collective disposition: If the reorder level of an article was reached, a check of all articles of the same delivery point takes place. This checks whether the difference between the current target stock and the ACTUAL stock is greater than the minimum replenishment quantity. In the amount of the target stock difference a collective order is then triggered.

Outside of intralogistics, two reorder point procedures are also distinguished, respectively, two methods are mainly used; on the one hand, the reorder point system and on the other hand, the order rhythm system. The former is comparable to the two above. The latter, on the other hand, is based on a fixed frequency, independent of the actual stock level, which is why it is mainly and almost exclusively used when the consumption of goods can be planned well in advance, based on a calculated reorder point.

Compared to the staging procedure and the cycle time procedure, the advantage of the reorder point procedure is the optimal inventory level. The disadvantages are the more difficult replenishment coordination and the partially delayed replenishment time. Furthermore, the reorder point must be calculated optimally, for which there are various options, depending on the numerous specifications that can be incorporated into it.

Replenishment – cycle time procedure

The cycle time procedure is especially suitable for MRP without computer support or if replenishment is to be carried out only according to a specified MRP cycle. The characteristic of the cycle time method is the time dependency.

A predefined replenishment cycle is helpful so that the person planning the use of suppliers does not have to take action for each individual order. In addition, the cycle time method allows the supplier to deliver in regular tours. Common forms of replenishment scheduling are monthly scheduling, weekly scheduling, or even daily scheduling.

There are two replenishment options in the cycle time method:

- Cyclical single replenishment

Independently of each other, a check is made for each article at a certain point in time to see whether the reorder point is undercut by the following MRP time. If this is the case, an order is placed in the amount of the optimum replenishment quantity.

- Cyclical collective disposition

For all articles of the same delivery point, it is checked at a certain time whether the target stock difference is greater than the required replenishment quantity. If more articles are required, a collective order is triggered at the relevant delivery point.

On average, the optimum replenishment quantity is delivered half a period length too early. Compared with the reorder point procedure, therefore, the average stock level is greater in cycle time replenishment planning. The possible replenishment reconciliation for several articles at the same time is to be regarded as an advantage. The disadvantages are the high space costs and the limited space available per article.

Replenishment planning in intralogistics

A key function that must be closely interlocked with picking is the classic replenishment from the main warehouse (reserve warehouse) directly to the picking zone. This is also the reason why the warehouse topology already takes an essential role during warehouse planning.

A replenishment warehouse can be divided into several distinct areas according to the groups of goods or the corresponding load carriers (pallet, carton, plastic container or other conveying equipment). In such a separation, the replenishment area with large stocking capacity usually stores several complete logistics units of a good, for example, fully loaded pallets. In the picking area, on the other hand, there are primarily opened logistics units. If these run low, corresponding units are replenished from the replenishment warehouse. Advantage: In this way, the number of units in the picking area is kept small, making it easier for employees to access them.

The challenge in supply planning:

- Different storage location types (pallet, small parts)

- different warehouse design: alley way, through alley, one way, dead end

- different tools: lift truck, forklift, human with or without cart

Replenishment – key figures

Appropriate warehouse metrics can be used to assess both the efficiency and the productivity and quality of replenishment. Therefore, the following key figures are important for the control center:

- The number of replenishment cycles

- The number of replenishment movements (stock transfers)

- The number of golden cartons (golden cartons are cartons of inventory that can be completely routed from the warehouse to the sorter(packinghouse) without having to go through the picking process first)

- Start and end of replenishment

- Retrieval and delivery tray (source and destination)

To measure the goals of stock supply and replenishment, the metrics on the following steps play a role:

- Travel share

- Capacity utilization

- Work progress

- Missing quantity

The recipients of the key figures are the logistics manager, the warehouse manager and other employees who work in the warehouse.

Summary

Replenishment is an immensely important process to ensure the production or delivery capacity of commercial and industrial enterprises. Different replenishment variants are used in a warehouse or factory: manual replenishment, preemptive replenishment and demand replenishment. Depending on which trigger criteria are used for replenishment, this results in three replenishment procedures, each of which depends on consumption, stock or time: staging procedure, reorder point procedure and cycle time procedure.

These are combined with three options concerning the replenishment quantity: minimum replenishment quantity, optimum replenishment quantity and replenishment quantity to a target stock.

The task of replenishment and corresponding strategies is to ensure a high availability of materials and inventories in the respective warehouses and work stations. At best, this is an efficient and economical way to maintain minimum stock levels, avoid out-of-stocks and ensure a smooth flow of materials.

For more information in the replenishment context, see also Picking, POS system, warehouse management and store logistics, Ship to Line / the direct provision of goods, Buffer line as well as Zero transit.

Also available in Deutsch (German)