In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles the shipment and delivers it directly to the point of consumption – without the need for the customer’s warehouse or logistics. By taking over the value-adding processes such as goods receipt, storage and retrieval by the supplier or manufacturer, an increase in the efficiency of the supply chain is facilitated.

The focus in the direct supply of inventory and raw materials is on replenishment. It can be achieved, for example, through continuous replenishment. In this process, the producer coordinates demand together with the supplier, based on the collected production quantities (production planning). For example, through the lean method Heijunka. This type of replenishment is carried out quickly and usually without a planning lead time (material requirements planning). The supplier can also be the manufacturer at the same time.

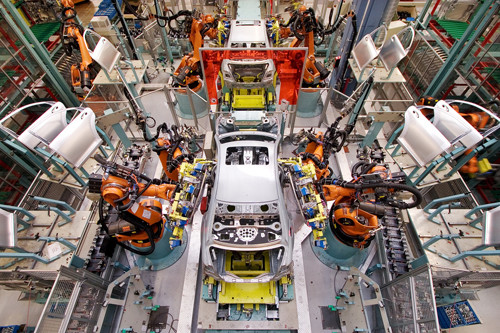

Ship to Line in practice (example): The inventory or raw material is organized directly to a production line (production) or assembly by the supplier. The producer does not engage in any warehousing activities. The delivered inventory is immediately collected by the department of production and is not stored temporarily. If a certain quantity of the required product is processed, automated quantity recording triggers replenishment; for example, through the kanban system or the milkrun concept – supply via the continuous goods supply mentioned above is also conceivable.

Ship to Line goals:

- Inventories are significantly reduced

- Replacement times are shortened

- Quality improvement through continuity

- Better transparency in the processes

- Processes are simplified

- Storage space requirements are reduced

- Cost savings

If the partners manage to meet the targets, this automatically minimizes the utilizationof resources or operating funds. The following applies: The closer the theoretical value (simulation in the supply chain) approaches the real value (key figures), the better the actual utilization rate during the real production phase.

Ship to Line issues:

- If there are major fluctuations in demand (bullwhip effect), shortages may occur in the long term. It therefore makes sense to constantly monitor and reassess replenishment.

- Quality of the inventory: If defective inventory is delivered, the defects usually remain unnoticed until sale or installation (assembly, production) because there is no inventory control on the part of the customer (buyer). As a result, downtime or other disruptions may occur in the supply chain (assembly and production lines are disrupted). Supplier and customer should therefore consider a process that allows the inward and outward transfer of customer complaints as well as spare parts; without hindering the actual line (delivery, production).

- Dependency: The dissolution of previous in-house warehouses increases dependency on the performance of the external supplier and its logistics processes. A precise agreement and contractually assured statements between customer and supplier are therefore imperative.

Ship to Line makes sense under the following conditions:

- Delivery time is shorter than that of the competition (proximity to the production site is an advantage)

- Quality is flawless

- Product variety is small (concentration on only a few products)

- Consumption rate of goods is high

- Product size is small (No furniture or other bulky parts)

For more information, see Just-in-time and Just-in-sequence, two other forms of goods provisioning.

Image rights: Daimler AG / CC BY-NC-ND 2.0

Also available in Deutsch (German)