Business processes in intralogistics

28. March 2024

PPE in logistics – protective and safety gloves

The logistics industry in Germany is the third largest economic sector after the automotive…

14. April 2022

Advantages and definition of the transhipment type cross docking

There are various handling methods for inventory in the shipping area. One of these handling…

20. April 2021

Definition and overview of the logistic process shipping and the common shipping types

What is included in the business process of shipping?The transport of goods from a company’s…

27. July 2020

Definition of business rules and fields of application of BRMS solutions

Business rules describe rules that are defined for automated processes or for processes whose…

7. May 2020

Single-stage picking – order-oriented, parallel picking

With parallel picking, an order is divided between different picking zones and processed…

7. May 2020

The Bullwhip effect

The bullwhip effect describes coordination and communication problems in multi-stage supply chains…

17. February 2020

Definition and overview of goods issue in intralogistics

Just as with goods receipt, goods issue is an interface between internal and external materials…

3. February 2020

Goods Receipt in intralogistics – definition and overview

The design and scope of the goods receipt are relevant for the performance of a warehouse. If the…

3. May 2019

SAIL – the system architecture for intralogistics from VDI / VDMA

"Innovation and Standardization" is the title of a working group of the Intralogistics Forum of the…

15. January 2019

Artificial intelligence (AI) and logistics

Artificial Intelligence (AI) can be defined as intelligence that originates exclusively from…

28. September 2018

Uses of Blockchain technology in logistics / intralogistics

Blockchain is an enabling technology. Just like the Internet, it harbors technological properties…

15. August 2018

The Jidoka principle in production and logistics

The Jidoka principle describes the ability of a machine, a plant or an entire system to switch…

10. July 2018

Set-up time in production and intralogistics

If a machine or a production site, i.e. individual facilities or entire production lines, is set up…

24. May 2018

Logistics management and the supply chain

The integrated planning, organization, management, processing and control of the entire flow of…

6. March 2018

Opportunity costs in logistics

Opportunity costs, also known as alternative costs or foregone costs, express a foregone benefit in…

8. January 2018

CPFR – Collaborative Planning, Forecasting and Replenishment

CPFR stands for Collaborative Planning, Forecasting and Replenishment and is a further development…

12. May 2017

The Supply Chain Management (SCM)

Supply chain management (SCM) stands for the monitoring process as well as the coordination and…

19. December 2016

Lean management: the 5S-method

The 5S method originates from Japanese production and was first used by the car manufacturer…

24. August 2016

Inventory costs

Inventory costs are costs that arise from the movement of product goods in the warehouse or…

12. May 2016

Specifications and requirement documents in intralogistics

The specification sheet generally contains the project requirements predefined and described in…

14. December 2015

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

21. September 2015

Information in intralogistics

Information describes the meaningful content of a message, which is of value for the recipient. The…

18. September 2015

Returns processing

Returns handling describes several processes in the return of goodsordered - mostly - online. They…

31. July 2015

Definition of order processing in intralogistics

Order processing includes all formal processes such as order transmission, data processing and…

17. April 2015

Lean Production

Lean Production describes a method with the goal to react quickly to outside influences on…

6. March 2015

Order throughput time

When an order is received in a logistics centre, it passes through various processes until it is…

10. October 2014

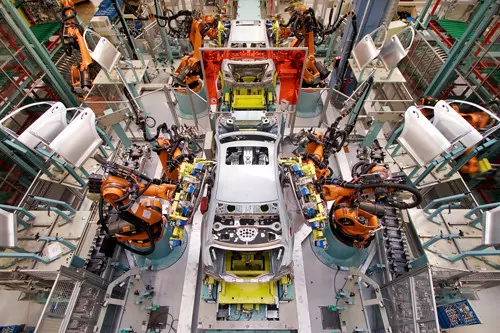

Production management

According to business economist Werner Kern, production management is an operational service…

24. February 2014

Batch formation in picking

Batch formation during picking, also known as batch picking or multi-order picking, is a form of…

20. December 2013

Definition – Value chain

A value chain describes how value is created through a chain of activities and combined in…

10. December 2013

Sorter (Packing) – Basics

After the picking business process, the product is passed on to the sorter (packing department).…

4. December 2013

Single-stage picking – basics

During picking, a certain quantity of articles is picked from an assortment and put together.…

21. November 2013

Picking – definition and picking methods

Picking stands for the assembly of goods and merchandise according to specified orders from an…

25. September 2013

Material throughput time

The material throughput time is the time required to run through all business processes, for…

15. July 2013

Basic warehouse planning – actual state analysis and target concept

Once the target has been set, an actual state analysis including the identification of weak points…

15. July 2013

Single-stage order picking – order-oriented, serial picking

With order-oriented, serial picking, order items are successively processed according to orders.…

12. July 2013

Sorter – Packaging

Definition of Packing The packaging is the merging of storage units to form a complete unit. In the…

9. July 2013

The manual sort order fulfilment

Manual Sort Order Fulfilment (MSF) is a software-supported, manual sorting system. The basis is a…

5. July 2013

Single-stage picking without IT system support

Picking without IT system support requires a manageable assortment of articles, which is clearly…

24. June 2013

Definition of business processes

Business processes can be used to visualize business-relevant procedures of a company. A task that…

19. June 2013

The modern material flow control

The Material Flow Control System (MFCS) or the Material Flow Computer (MFC) is very often described…

28. March 2024

PPE in logistics – protective and safety gloves

The logistics industry in Germany is the third largest economic sector after the automotive…

14. April 2022

Advantages and definition of the transhipment type cross docking

There are various handling methods for inventory in the shipping area. One of these handling…

20. April 2021

Definition and overview of the logistic process shipping and the common shipping types

What is included in the business process of shipping?The transport of goods from a company’s…

27. July 2020

Definition of business rules and fields of application of BRMS solutions

Business rules describe rules that are defined for automated processes or for processes whose…

7. May 2020

Single-stage picking – order-oriented, parallel picking

With parallel picking, an order is divided between different picking zones and processed…

7. May 2020

The Bullwhip effect

The bullwhip effect describes coordination and communication problems in multi-stage supply chains…

17. February 2020

Definition and overview of goods issue in intralogistics

Just as with goods receipt, goods issue is an interface between internal and external materials…

3. February 2020

Goods Receipt in intralogistics – definition and overview

The design and scope of the goods receipt are relevant for the performance of a warehouse. If the…

3. May 2019

SAIL – the system architecture for intralogistics from VDI / VDMA

"Innovation and Standardization" is the title of a working group of the Intralogistics Forum of the…

15. January 2019

Artificial intelligence (AI) and logistics

Artificial Intelligence (AI) can be defined as intelligence that originates exclusively from…

28. September 2018

Uses of Blockchain technology in logistics / intralogistics

Blockchain is an enabling technology. Just like the Internet, it harbors technological properties…

15. August 2018

The Jidoka principle in production and logistics

The Jidoka principle describes the ability of a machine, a plant or an entire system to switch…

10. July 2018

Set-up time in production and intralogistics

If a machine or a production site, i.e. individual facilities or entire production lines, is set up…

24. May 2018

Logistics management and the supply chain

The integrated planning, organization, management, processing and control of the entire flow of…

6. March 2018

Opportunity costs in logistics

Opportunity costs, also known as alternative costs or foregone costs, express a foregone benefit in…

8. January 2018

CPFR – Collaborative Planning, Forecasting and Replenishment

CPFR stands for Collaborative Planning, Forecasting and Replenishment and is a further development…

12. May 2017

The Supply Chain Management (SCM)

Supply chain management (SCM) stands for the monitoring process as well as the coordination and…

19. December 2016

Lean management: the 5S-method

The 5S method originates from Japanese production and was first used by the car manufacturer…

24. August 2016

Inventory costs

Inventory costs are costs that arise from the movement of product goods in the warehouse or…

12. May 2016

Specifications and requirement documents in intralogistics

The specification sheet generally contains the project requirements predefined and described in…

14. December 2015

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

21. September 2015

Information in intralogistics

Information describes the meaningful content of a message, which is of value for the recipient. The…

18. September 2015

Returns processing

Returns handling describes several processes in the return of goodsordered - mostly - online. They…

31. July 2015

Definition of order processing in intralogistics

Order processing includes all formal processes such as order transmission, data processing and…

17. April 2015

Lean Production

Lean Production describes a method with the goal to react quickly to outside influences on…

6. March 2015

Order throughput time

When an order is received in a logistics centre, it passes through various processes until it is…

10. October 2014

Production management

According to business economist Werner Kern, production management is an operational service…

24. February 2014

Batch formation in picking

Batch formation during picking, also known as batch picking or multi-order picking, is a form of…

20. December 2013

Definition – Value chain

A value chain describes how value is created through a chain of activities and combined in…

10. December 2013

Sorter (Packing) – Basics

After the picking business process, the product is passed on to the sorter (packing department).…

4. December 2013

Single-stage picking – basics

During picking, a certain quantity of articles is picked from an assortment and put together.…

21. November 2013

Picking – definition and picking methods

Picking stands for the assembly of goods and merchandise according to specified orders from an…

25. September 2013

Material throughput time

The material throughput time is the time required to run through all business processes, for…

15. July 2013

Basic warehouse planning – actual state analysis and target concept

Once the target has been set, an actual state analysis including the identification of weak points…

15. July 2013

Single-stage order picking – order-oriented, serial picking

With order-oriented, serial picking, order items are successively processed according to orders.…

12. July 2013

Sorter – Packaging

Definition of Packing The packaging is the merging of storage units to form a complete unit. In the…

9. July 2013

The manual sort order fulfilment

Manual Sort Order Fulfilment (MSF) is a software-supported, manual sorting system. The basis is a…

5. July 2013

Single-stage picking without IT system support

Picking without IT system support requires a manageable assortment of articles, which is clearly…

24. June 2013

Definition of business processes

Business processes can be used to visualize business-relevant procedures of a company. A task that…

19. June 2013

The modern material flow control

The Material Flow Control System (MFCS) or the Material Flow Computer (MFC) is very often described…