Inventory management

8. September 2023

Advance Shipping Notice

An Advance Shipping Notice (ASN), also advice note or avis, is a piece of preliminary information…

21. January 2022

Definition of replenishment in transport and intralogistics

Replenishment is a fundamentally important process in today's enterprise resource planning. With…

7. July 2020

Rack zones – Overview

A storage rack, both in intralogistics and retail, can be divided into different horizontal racking…

7. May 2020

The Bullwhip effect

The bullwhip effect describes coordination and communication problems in multi-stage supply chains…

7. May 2020

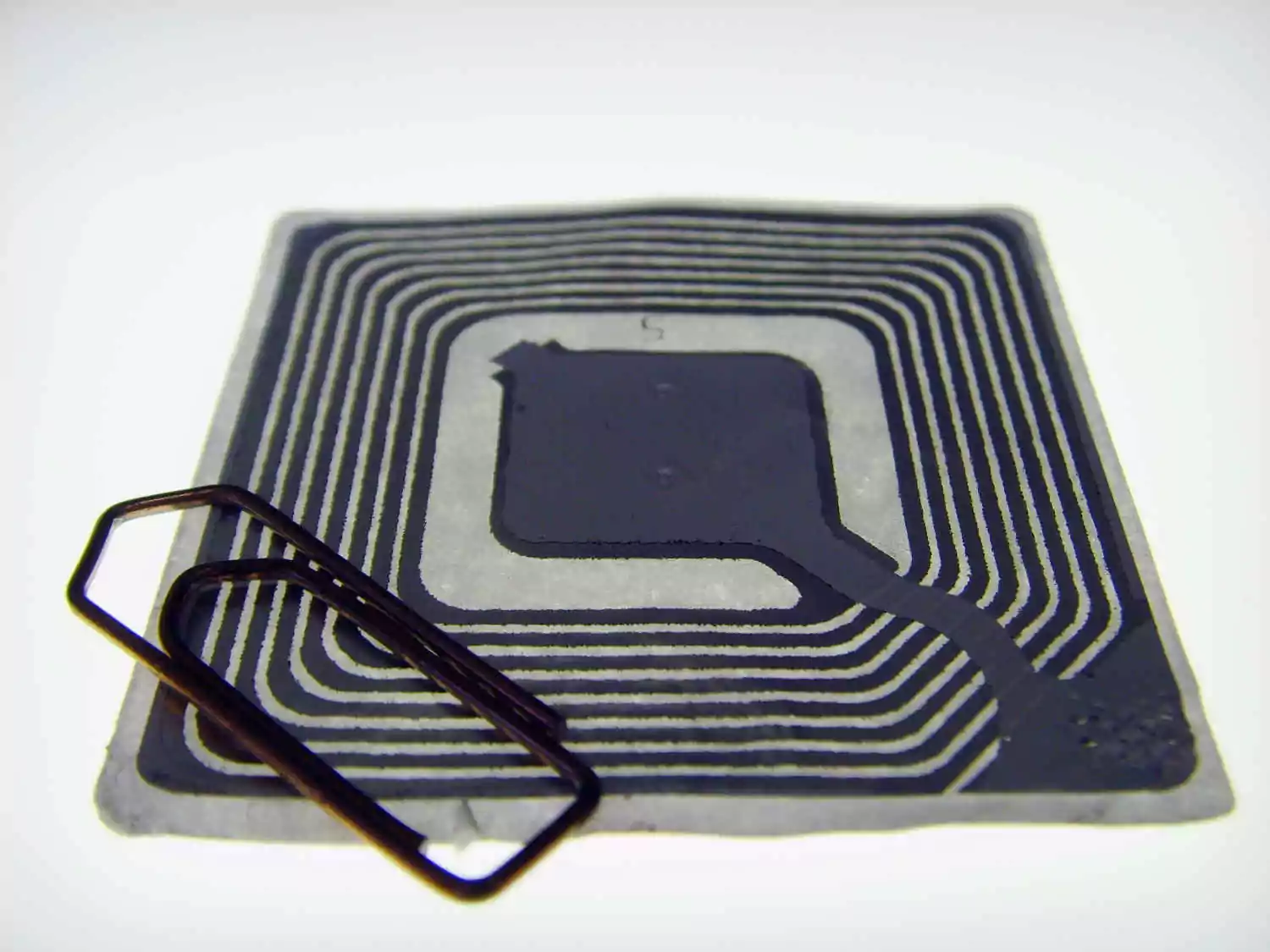

Radio Frequency Identification (RFID)

Radio Frequency Identification (RFID) is a technology for the unambiguous and contact-free…

1. April 2020

Turnover rate and Rotation of goods: Fast and slow movers

The inventory turnover, also known as the inventory turnover rate or inventory turnover…

25. November 2019

Allocation strategies for warehouse and picking systems/warehouse operation strategies

In a company, it is vital to set goals before developing strategies and to monitor their…

6. February 2019

Advantages and disadvantages: centralized and decentralized warehouse

In distribution logistics, the determination of warehouse locations represents a strategic…

7. November 2018

Inventory in companies and in logistics

In the inventory, the assets of a company are determined on a key date; in this way, assets and…

28. September 2018

Uses of Blockchain technology in logistics / intralogistics

Blockchain is an enabling technology. Just like the Internet, it harbors technological properties…

29. August 2018

Storage maintenance costs – warehousing costs or storage costs

Trading companies and manufacturing companies usually have a warehouse or distribution centre. Raw…

31. July 2018

Point of sale systems, warehouse management and branch logistics

A cash register system, also known as a POS system, is software that documents a specific financial…

27. June 2018

The range of storage

The range of storage is a key figure which expresses the internal security of supply by own stocks…

28. November 2017

At a glance: the enterprise resource planning system

An enterprise resource planning system is a software that ensures a smooth flow of commercial…

1. August 2017

Product Lifecycle Management (PLM)

The term Product Lifecycle Management, PLM for short, describes a holistic approach to pooling…

12. May 2017

The Supply Chain Management (SCM)

Supply chain management (SCM) stands for the monitoring process as well as the coordination and…

30. March 2017

Conveying aids in intralogistics

In intralogistics, conveying equipment is used to combine individual goods into larger load units.…

22. March 2017

Order picking times – Dead time

Dead time is an unproductive but unavoidable so-called auxiliary time, which arises during picking…

23. February 2017

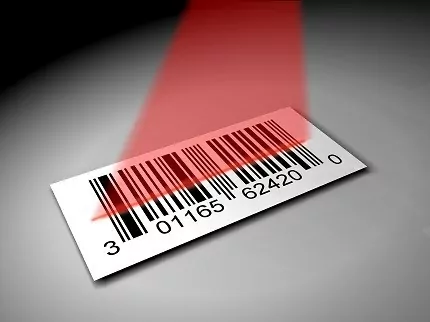

Advantages of RFID technology over barcodes

What advantages does RFID radio technology have over barcodes? This question has also been on the…

9. February 2017

The storage location management

The storage location management ensures that a storage location is recorded or occupied in width,…

12. January 2017

Materials management in production and logistics

Materials management controls the material flow within a company as well as order-related material…

19. September 2016

Distributed Order Management

Distributed Order Management basically the consideration of all companies involved in an order as…

24. August 2016

Inventory costs

Inventory costs are costs that arise from the movement of product goods in the warehouse or…

19. July 2016

Inventory management in intralogistics, incl. stock and stock reconciliation

Inventory management stands for the complete digital recording of all stock movements in…

25. April 2016

Definition – WMS – The Warehouse Management System

The Warehouse Management System (WMS) is an indispensable software for the control and…

7. April 2016

CMR: the consignment note

The term CMR comes from the French, Convention relative au Contrat de transport international de…

7. March 2016

Stock Keeping Unit (SKU)

The acronym SKU, Stock Keeping Unit, describes a clearly identifiable storage unit. A storage unit…

26. January 2016

The Newsvendor Model in SCM

Many supply chain management (SCM) approaches can be explained using the Newsvendor Model (NVM).…

15. January 2016

The cost of unused opportunities in supply chain management

No company can afford not to have the cost side under control. The figures from financial…

14. December 2015

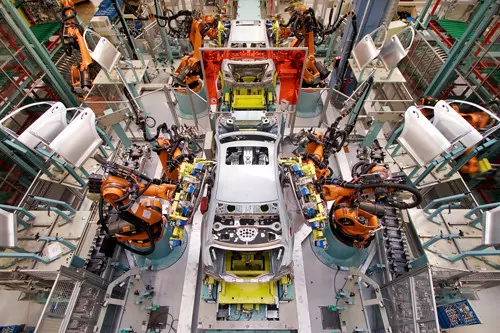

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

7. December 2015

Definition – The Milk Run Concept

The milk run concept is a method for optimizing inter-company procurement logistics, often used in…

1. December 2015

The degree of utilisation/the capacity utilisation

The degree of capacity utilisation describes the proportion of the capacity used by…

21. September 2015

Information in intralogistics

Information describes the meaningful content of a message, which is of value for the recipient. The…

18. September 2015

Returns processing

Returns handling describes several processes in the return of goodsordered - mostly - online. They…

14. September 2015

Storage capacity/storage economy

Storage capacity is defined as the maximum number of loading units that a warehouse can hold. It…

26. August 2015

Host system (ERP system)

The host system (usually an ERP system) is a central data processing system that can be accessed…

22. July 2015

Heijunka lean method

The Japanese lean method Heijunka pushes a production where the production flow of the parts market…

10. July 2015

Assortment width and assortment depth

The assortment available in a warehouse and in the retail trade is subdivided into the assortment…

14. April 2015

The distribution center

A distribution center is an interface in the form of a building complex that functions exclusively…

23. February 2015

The barcode – EAN, GTIN and GS1 standard

Barcodes have successfully established themselves over other systems in recent years. The barcode…

8. January 2015

Temperature-controlled logistics (environmental measurement)

The market for temperature-controlled logistics in particular has been growing in volume over the…

2. December 2014

Overview and definition of ident carriers

In order to be able to identify an object without any doubt throughout the entire logistics chain,…

16. September 2014

Data Mart: the local warehouse database analysis

Data mart describes the use of a database that is only a department-specific part of the overall…

8. September 2014

Overview – Serial Shipping Container Code (SSCC)

Each shipping unit, which can be a pallet or a carton, for example, is automatically assigned a…

27. June 2014

Defintion and advantages of consignment

The term consignment refers to a form of delivery of goods in which the supplier acts as consignor…

19. March 2014

Master data

In intralogistics, master data, also known as primary data or reference data, is data that contains…

3. February 2014

Storage and retrieval machine

A storage and retrieval machine (SRM) is a storage device with which load units can be stored,…

14. November 2013

Overview of common manufacturing principles

Different principles can be applied in manufacturing. Some products are manufactured according to…

17. September 2013

Mobile and stationary loading units

Loading units are collections of goods that are transported, transhipped or stored as they pass…

15. July 2013

Overview of “Last-in-First-out” and “First-in-First-out” storage strategies

LIFO (last-in-first-out) and FIFO (first-in-first-out) are two different strategies for storing and…

- 1

- 2

8. September 2023

Advance Shipping Notice

An Advance Shipping Notice (ASN), also advice note or avis, is a piece of preliminary information…

21. January 2022

Definition of replenishment in transport and intralogistics

Replenishment is a fundamentally important process in today's enterprise resource planning. With…

7. July 2020

Rack zones – Overview

A storage rack, both in intralogistics and retail, can be divided into different horizontal racking…

7. May 2020

The Bullwhip effect

The bullwhip effect describes coordination and communication problems in multi-stage supply chains…

7. May 2020

Radio Frequency Identification (RFID)

Radio Frequency Identification (RFID) is a technology for the unambiguous and contact-free…

1. April 2020

Turnover rate and Rotation of goods: Fast and slow movers

The inventory turnover, also known as the inventory turnover rate or inventory turnover…

25. November 2019

Allocation strategies for warehouse and picking systems/warehouse operation strategies

In a company, it is vital to set goals before developing strategies and to monitor their…

6. February 2019

Advantages and disadvantages: centralized and decentralized warehouse

In distribution logistics, the determination of warehouse locations represents a strategic…

7. November 2018

Inventory in companies and in logistics

In the inventory, the assets of a company are determined on a key date; in this way, assets and…

28. September 2018

Uses of Blockchain technology in logistics / intralogistics

Blockchain is an enabling technology. Just like the Internet, it harbors technological properties…

29. August 2018

Storage maintenance costs – warehousing costs or storage costs

Trading companies and manufacturing companies usually have a warehouse or distribution centre. Raw…

31. July 2018

Point of sale systems, warehouse management and branch logistics

A cash register system, also known as a POS system, is software that documents a specific financial…

27. June 2018

The range of storage

The range of storage is a key figure which expresses the internal security of supply by own stocks…

28. November 2017

At a glance: the enterprise resource planning system

An enterprise resource planning system is a software that ensures a smooth flow of commercial…

1. August 2017

Product Lifecycle Management (PLM)

The term Product Lifecycle Management, PLM for short, describes a holistic approach to pooling…

12. May 2017

The Supply Chain Management (SCM)

Supply chain management (SCM) stands for the monitoring process as well as the coordination and…

30. March 2017

Conveying aids in intralogistics

In intralogistics, conveying equipment is used to combine individual goods into larger load units.…

22. March 2017

Order picking times – Dead time

Dead time is an unproductive but unavoidable so-called auxiliary time, which arises during picking…

23. February 2017

Advantages of RFID technology over barcodes

What advantages does RFID radio technology have over barcodes? This question has also been on the…

9. February 2017

The storage location management

The storage location management ensures that a storage location is recorded or occupied in width,…

12. January 2017

Materials management in production and logistics

Materials management controls the material flow within a company as well as order-related material…

19. September 2016

Distributed Order Management

Distributed Order Management basically the consideration of all companies involved in an order as…

24. August 2016

Inventory costs

Inventory costs are costs that arise from the movement of product goods in the warehouse or…

19. July 2016

Inventory management in intralogistics, incl. stock and stock reconciliation

Inventory management stands for the complete digital recording of all stock movements in…

25. April 2016

Definition – WMS – The Warehouse Management System

The Warehouse Management System (WMS) is an indispensable software for the control and…

7. April 2016

CMR: the consignment note

The term CMR comes from the French, Convention relative au Contrat de transport international de…

7. March 2016

Stock Keeping Unit (SKU)

The acronym SKU, Stock Keeping Unit, describes a clearly identifiable storage unit. A storage unit…

26. January 2016

The Newsvendor Model in SCM

Many supply chain management (SCM) approaches can be explained using the Newsvendor Model (NVM).…

15. January 2016

The cost of unused opportunities in supply chain management

No company can afford not to have the cost side under control. The figures from financial…

14. December 2015

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

7. December 2015

Definition – The Milk Run Concept

The milk run concept is a method for optimizing inter-company procurement logistics, often used in…

1. December 2015

The degree of utilisation/the capacity utilisation

The degree of capacity utilisation describes the proportion of the capacity used by…

21. September 2015

Information in intralogistics

Information describes the meaningful content of a message, which is of value for the recipient. The…

18. September 2015

Returns processing

Returns handling describes several processes in the return of goodsordered - mostly - online. They…

14. September 2015

Storage capacity/storage economy

Storage capacity is defined as the maximum number of loading units that a warehouse can hold. It…

26. August 2015

Host system (ERP system)

The host system (usually an ERP system) is a central data processing system that can be accessed…

22. July 2015

Heijunka lean method

The Japanese lean method Heijunka pushes a production where the production flow of the parts market…

10. July 2015

Assortment width and assortment depth

The assortment available in a warehouse and in the retail trade is subdivided into the assortment…

14. April 2015

The distribution center

A distribution center is an interface in the form of a building complex that functions exclusively…

23. February 2015

The barcode – EAN, GTIN and GS1 standard

Barcodes have successfully established themselves over other systems in recent years. The barcode…

8. January 2015

Temperature-controlled logistics (environmental measurement)

The market for temperature-controlled logistics in particular has been growing in volume over the…

2. December 2014

Overview and definition of ident carriers

In order to be able to identify an object without any doubt throughout the entire logistics chain,…

16. September 2014

Data Mart: the local warehouse database analysis

Data mart describes the use of a database that is only a department-specific part of the overall…

8. September 2014

Overview – Serial Shipping Container Code (SSCC)

Each shipping unit, which can be a pallet or a carton, for example, is automatically assigned a…

27. June 2014

Defintion and advantages of consignment

The term consignment refers to a form of delivery of goods in which the supplier acts as consignor…

19. March 2014

Master data

In intralogistics, master data, also known as primary data or reference data, is data that contains…

3. February 2014

Storage and retrieval machine

A storage and retrieval machine (SRM) is a storage device with which load units can be stored,…

14. November 2013

Overview of common manufacturing principles

Different principles can be applied in manufacturing. Some products are manufactured according to…

17. September 2013

Mobile and stationary loading units

Loading units are collections of goods that are transported, transhipped or stored as they pass…

15. July 2013

Overview of “Last-in-First-out” and “First-in-First-out” storage strategies

LIFO (last-in-first-out) and FIFO (first-in-first-out) are two different strategies for storing and…