Key figures

21. January 2022

Definition of replenishment in transport and intralogistics

Replenishment is a fundamentally important process in today's enterprise resource planning. With…

8. September 2020

Key figures and key figure systems

Table of contents for easier navigation of the post: Key figures Functions of key figures…

7. May 2020

The Bullwhip effect

The bullwhip effect describes coordination and communication problems in multi-stage supply chains…

1. April 2020

Turnover rate and Rotation of goods: Fast and slow movers

The inventory turnover, also known as the inventory turnover rate or inventory turnover…

7. November 2018

Inventory in companies and in logistics

In the inventory, the assets of a company are determined on a key date; in this way, assets and…

29. August 2018

Storage maintenance costs – warehousing costs or storage costs

Trading companies and manufacturing companies usually have a warehouse or distribution centre. Raw…

27. June 2018

The range of storage

The range of storage is a key figure which expresses the internal security of supply by own stocks…

6. March 2018

Opportunity costs in logistics

Opportunity costs, also known as alternative costs or foregone costs, express a foregone benefit in…

8. January 2018

CPFR – Collaborative Planning, Forecasting and Replenishment

CPFR stands for Collaborative Planning, Forecasting and Replenishment and is a further development…

5. December 2017

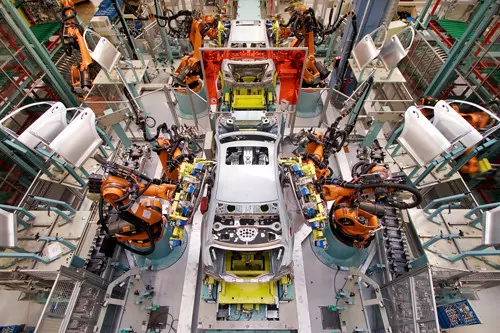

Networked Production: Computer-integrated Manufacturing

Computer-integrated manufacturing, or CIM for short, stands for computer-controlled machine and…

18. July 2017

The control center in intralogistics

The control panel in intralogistics represents a central point of a warehouse management system and…

23. May 2017

Smart Data

Smart Data stands for the detailed and structured result of an analysis of unstructured data masses…

12. May 2017

The Supply Chain Management (SCM)

Supply chain management (SCM) stands for the monitoring process as well as the coordination and…

18. April 2017

Key figure system in intralogistics

Although a complete bundling of all key figures arising in warehouse and distribution systems is…

1. February 2017

Perfect Order Fulfillment

The so-called Perfect Order Fulfillment stands for the perfect degree of fulfillment of the…

21. November 2016

The end of the 6 Rs of logistics? – Part 2

The classic logistics view is limited to the now famous 6 R's with regard to its tasks - as already…

7. November 2016

The end of the 6 Rs of logistics? – Part 1

The tasks of logistics and the logistician are memorably explained with the famous 6 Rs. The 6 Rs…

24. August 2016

Inventory costs

Inventory costs are costs that arise from the movement of product goods in the warehouse or…

25. April 2016

Definition – WMS – The Warehouse Management System

The Warehouse Management System (WMS) is an indispensable software for the control and…

7. March 2016

Stock Keeping Unit (SKU)

The acronym SKU, Stock Keeping Unit, describes a clearly identifiable storage unit. A storage unit…

14. December 2015

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

1. December 2015

The degree of utilisation/the capacity utilisation

The degree of capacity utilisation describes the proportion of the capacity used by…

2. November 2015

Definition of Accounting / Bookkeeping

The term accounting describes the comprehensive recording, storage and analysis or evaluation of…

21. September 2015

Information in intralogistics

Information describes the meaningful content of a message, which is of value for the recipient. The…

14. September 2015

Storage capacity/storage economy

Storage capacity is defined as the maximum number of loading units that a warehouse can hold. It…

14. April 2015

The distribution center

A distribution center is an interface in the form of a building complex that functions exclusively…

16. September 2014

Data Mart: the local warehouse database analysis

Data mart describes the use of a database that is only a department-specific part of the overall…

19. March 2014

Master data

In intralogistics, master data, also known as primary data or reference data, is data that contains…

25. September 2013

Material throughput time

The material throughput time is the time required to run through all business processes, for…

16. September 2013

Potential analysis in intralogistics

A potential analysis is a comparison of company performance with the given expectations for said…

16. September 2013

Performance analysis in logistics

A performance analysis examines various service points in logistics for their contribution to value…

12. July 2013

Enterprise Resource Planning System (ERP System)

As an application program, an enterprise resource planning system (ERP system) supports all task…

12. July 2013

Production data acquisition

Operating data is data from organisational and technical areas of a company. This includes order…

21. January 2022

Definition of replenishment in transport and intralogistics

Replenishment is a fundamentally important process in today's enterprise resource planning. With…

8. September 2020

Key figures and key figure systems

Table of contents for easier navigation of the post: Key figures Functions of key figures…

7. May 2020

The Bullwhip effect

The bullwhip effect describes coordination and communication problems in multi-stage supply chains…

1. April 2020

Turnover rate and Rotation of goods: Fast and slow movers

The inventory turnover, also known as the inventory turnover rate or inventory turnover…

7. November 2018

Inventory in companies and in logistics

In the inventory, the assets of a company are determined on a key date; in this way, assets and…

29. August 2018

Storage maintenance costs – warehousing costs or storage costs

Trading companies and manufacturing companies usually have a warehouse or distribution centre. Raw…

27. June 2018

The range of storage

The range of storage is a key figure which expresses the internal security of supply by own stocks…

6. March 2018

Opportunity costs in logistics

Opportunity costs, also known as alternative costs or foregone costs, express a foregone benefit in…

8. January 2018

CPFR – Collaborative Planning, Forecasting and Replenishment

CPFR stands for Collaborative Planning, Forecasting and Replenishment and is a further development…

5. December 2017

Networked Production: Computer-integrated Manufacturing

Computer-integrated manufacturing, or CIM for short, stands for computer-controlled machine and…

18. July 2017

The control center in intralogistics

The control panel in intralogistics represents a central point of a warehouse management system and…

23. May 2017

Smart Data

Smart Data stands for the detailed and structured result of an analysis of unstructured data masses…

12. May 2017

The Supply Chain Management (SCM)

Supply chain management (SCM) stands for the monitoring process as well as the coordination and…

18. April 2017

Key figure system in intralogistics

Although a complete bundling of all key figures arising in warehouse and distribution systems is…

1. February 2017

Perfect Order Fulfillment

The so-called Perfect Order Fulfillment stands for the perfect degree of fulfillment of the…

21. November 2016

The end of the 6 Rs of logistics? – Part 2

The classic logistics view is limited to the now famous 6 R's with regard to its tasks - as already…

7. November 2016

The end of the 6 Rs of logistics? – Part 1

The tasks of logistics and the logistician are memorably explained with the famous 6 Rs. The 6 Rs…

24. August 2016

Inventory costs

Inventory costs are costs that arise from the movement of product goods in the warehouse or…

25. April 2016

Definition – WMS – The Warehouse Management System

The Warehouse Management System (WMS) is an indispensable software for the control and…

7. March 2016

Stock Keeping Unit (SKU)

The acronym SKU, Stock Keeping Unit, describes a clearly identifiable storage unit. A storage unit…

14. December 2015

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

1. December 2015

The degree of utilisation/the capacity utilisation

The degree of capacity utilisation describes the proportion of the capacity used by…

2. November 2015

Definition of Accounting / Bookkeeping

The term accounting describes the comprehensive recording, storage and analysis or evaluation of…

21. September 2015

Information in intralogistics

Information describes the meaningful content of a message, which is of value for the recipient. The…

14. September 2015

Storage capacity/storage economy

Storage capacity is defined as the maximum number of loading units that a warehouse can hold. It…

14. April 2015

The distribution center

A distribution center is an interface in the form of a building complex that functions exclusively…

16. September 2014

Data Mart: the local warehouse database analysis

Data mart describes the use of a database that is only a department-specific part of the overall…

19. March 2014

Master data

In intralogistics, master data, also known as primary data or reference data, is data that contains…

25. September 2013

Material throughput time

The material throughput time is the time required to run through all business processes, for…

16. September 2013

Potential analysis in intralogistics

A potential analysis is a comparison of company performance with the given expectations for said…

16. September 2013

Performance analysis in logistics

A performance analysis examines various service points in logistics for their contribution to value…

12. July 2013

Enterprise Resource Planning System (ERP System)

As an application program, an enterprise resource planning system (ERP system) supports all task…

12. July 2013

Production data acquisition

Operating data is data from organisational and technical areas of a company. This includes order…