Planning and organization of a warehouse

31. May 2024

What is warehousing? Overview and definition

In German, the English term “warehousing” is increasingly being used, which is in it…

8. September 2023

Advance Shipping Notice

An Advance Shipping Notice (ASN), also advice note or avis, is a piece of preliminary information…

15. June 2023

Personal Protective Equipment (PPE) in the Warehouse and in Intralogistics

Planning and organization of a warehouseAccording to the PPE Usage Ordinance, personal protective…

15. November 2021

Microfulfillment – definition and overview

Microfulfillment describes the decentralized and also customer-oriented execution of processes such…

1. July 2021

The factor Light in warehouse and logistics

The illumination of distribution centers is a rather rarely addressed aspect of warehousing. The…

7. July 2020

Rack zones – Overview

A storage rack, both in intralogistics and retail, can be divided into different horizontal racking…

7. May 2020

Single-stage picking – order-oriented, parallel picking

With parallel picking, an order is divided between different picking zones and processed…

7. May 2020

The Bullwhip effect

The bullwhip effect describes coordination and communication problems in multi-stage supply chains…

1. April 2020

Turnover rate and Rotation of goods: Fast and slow movers

The inventory turnover, also known as the inventory turnover rate or inventory turnover…

28. October 2019

Storage techniques in intralogistics

Depending on the nature of the stored goods and the frequency of use, different storage techniques…

8. October 2019

Swarm intelligence – What we logisticians can learn from ants – Part II

You may think estimating the weight of an ox, as described in Part 1 of this article, is hardly a…

4. October 2019

When risk minimization becomes a risk in logistics

Logistical decisions are ultimately economic decisions. This applies, for example, to major…

3. May 2019

SAIL – the system architecture for intralogistics from VDI / VDMA

"Innovation and Standardization" is the title of a working group of the Intralogistics Forum of the…

28. March 2019

Enterprise Resource Planning – the five most important questions when choosing an ERP system

An Enterprise Resource Planning System (ERP for short) is used in many different sized companies.…

6. February 2019

Advantages and disadvantages: centralized and decentralized warehouse

In distribution logistics, the determination of warehouse locations represents a strategic…

29. August 2018

Storage maintenance costs – warehousing costs or storage costs

Trading companies and manufacturing companies usually have a warehouse or distribution centre. Raw…

15. August 2018

The Jidoka principle in production and logistics

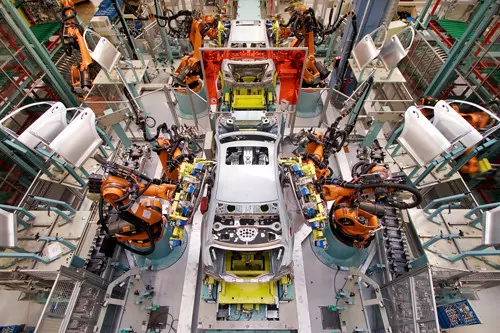

The Jidoka principle describes the ability of a machine, a plant or an entire system to switch…

10. July 2018

Set-up time in production and intralogistics

If a machine or a production site, i.e. individual facilities or entire production lines, is set up…

24. May 2018

Logistics management and the supply chain

The integrated planning, organization, management, processing and control of the entire flow of…

16. May 2018

Vogel’s approximation method

The approximation method according to Vogel is a heuristic procedure that is mainly used in…

6. March 2018

Opportunity costs in logistics

Opportunity costs, also known as alternative costs or foregone costs, express a foregone benefit in…

25. September 2017

Human-machine interfaces in the industry

The human-machine interface represents the analog or digital interaction interface between a…

18. September 2017

Kanban and swarm intelligence at management level

In manufacturing and industry, a supply concept called Kanban(Japanese for card or sign), invented…

18. July 2017

The control center in intralogistics

The control panel in intralogistics represents a central point of a warehouse management system and…

23. May 2017

Smart Data

Smart Data stands for the detailed and structured result of an analysis of unstructured data masses…

12. May 2017

The Supply Chain Management (SCM)

Supply chain management (SCM) stands for the monitoring process as well as the coordination and…

1. March 2017

Order picking – process steps

Picking stands for the combination of predefined orders from a warehouse assortment. The process…

9. February 2017

The storage location management

The storage location management ensures that a storage location is recorded or occupied in width,…

24. January 2017

The process-oriented warehouse planning

The process-oriented warehouse planning already takes into account in detail key positions relevant…

12. January 2017

Materials management in production and logistics

Materials management controls the material flow within a company as well as order-related material…

7. November 2016

The end of the 6 Rs of logistics? – Part 1

The tasks of logistics and the logistician are memorably explained with the famous 6 Rs. The 6 Rs…

17. October 2016

Swarm intelligence – What we logisticians can learn from ants – Part I

Surely you use a navigation system. So then you are already relying on the performance of ants and…

4. October 2016

Optimization through process chain management

Process chain management serves to organize business processes in intralogistics and other…

10. August 2016

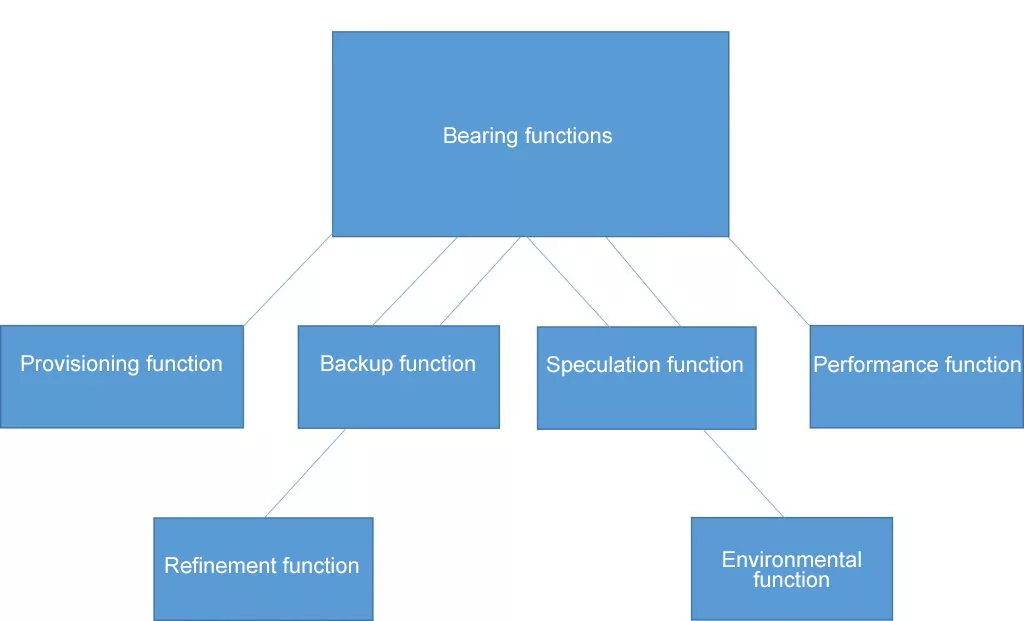

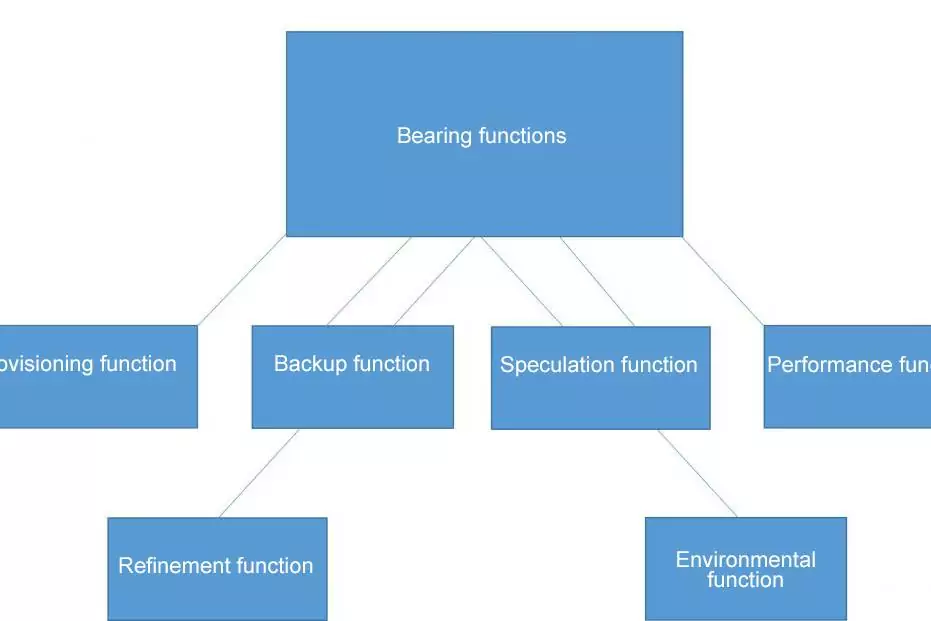

Functions of the warehouse

When considering the functions of a warehouse, the purpose of the warehouse arrangement is in the…

17. June 2016

Ergonomics in the warehouse

Ergonomics in the warehouse aims at the adaptation and creation of workstations which, taking into…

12. May 2016

Specifications and requirement documents in intralogistics

The specification sheet generally contains the project requirements predefined and described in…

25. April 2016

Definition – WMS – The Warehouse Management System

The Warehouse Management System (WMS) is an indispensable software for the control and…

26. February 2016

Picking times – base time

In picking, the base time is the time required for picking. It only describes organisational…

10. February 2016

Material flow control as a service for a distribution center

Material flow control, also known as material flow computer or material flow control system (MFCS),…

2. February 2016

Automated guided vehicles (AGVs)

From the technical committee of the VDI (Association of German Engineers), automated guided…

28. January 2016

Cut-off time in intralogistics

In intralogistics, the cut-off time describes the time at which an order must leave the warehouse…

18. January 2016

Function and advantages of the ant algorithm

The Ant Algorithm, also often called Ant Colony Optimization (ACO) in the literature, is an…

15. January 2016

The cost of unused opportunities in supply chain management

No company can afford not to have the cost side under control. The figures from financial…

14. December 2015

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

7. December 2015

Definition – The Milk Run Concept

The milk run concept is a method for optimizing inter-company procurement logistics, often used in…

1. December 2015

The degree of utilisation/the capacity utilisation

The degree of capacity utilisation describes the proportion of the capacity used by…

2. November 2015

Definition of Accounting / Bookkeeping

The term accounting describes the comprehensive recording, storage and analysis or evaluation of…

19. October 2015

Buffer line

A buffer section is used to intercept jams within the material flow, to avoid bottlenecks and idle…

18. September 2015

Returns processing

Returns handling describes several processes in the return of goodsordered - mostly - online. They…

14. September 2015

Storage capacity/storage economy

Storage capacity is defined as the maximum number of loading units that a warehouse can hold. It…

- 1

- 2

31. May 2024

What is warehousing? Overview and definition

In German, the English term “warehousing” is increasingly being used, which is in it…

8. September 2023

Advance Shipping Notice

An Advance Shipping Notice (ASN), also advice note or avis, is a piece of preliminary information…

15. June 2023

Personal Protective Equipment (PPE) in the Warehouse and in Intralogistics

Planning and organization of a warehouseAccording to the PPE Usage Ordinance, personal protective…

15. November 2021

Microfulfillment – definition and overview

Microfulfillment describes the decentralized and also customer-oriented execution of processes such…

1. July 2021

The factor Light in warehouse and logistics

The illumination of distribution centers is a rather rarely addressed aspect of warehousing. The…

7. July 2020

Rack zones – Overview

A storage rack, both in intralogistics and retail, can be divided into different horizontal racking…

7. May 2020

Single-stage picking – order-oriented, parallel picking

With parallel picking, an order is divided between different picking zones and processed…

7. May 2020

The Bullwhip effect

The bullwhip effect describes coordination and communication problems in multi-stage supply chains…

1. April 2020

Turnover rate and Rotation of goods: Fast and slow movers

The inventory turnover, also known as the inventory turnover rate or inventory turnover…

28. October 2019

Storage techniques in intralogistics

Depending on the nature of the stored goods and the frequency of use, different storage techniques…

8. October 2019

Swarm intelligence – What we logisticians can learn from ants – Part II

You may think estimating the weight of an ox, as described in Part 1 of this article, is hardly a…

4. October 2019

When risk minimization becomes a risk in logistics

Logistical decisions are ultimately economic decisions. This applies, for example, to major…

3. May 2019

SAIL – the system architecture for intralogistics from VDI / VDMA

"Innovation and Standardization" is the title of a working group of the Intralogistics Forum of the…

28. March 2019

Enterprise Resource Planning – the five most important questions when choosing an ERP system

An Enterprise Resource Planning System (ERP for short) is used in many different sized companies.…

6. February 2019

Advantages and disadvantages: centralized and decentralized warehouse

In distribution logistics, the determination of warehouse locations represents a strategic…

29. August 2018

Storage maintenance costs – warehousing costs or storage costs

Trading companies and manufacturing companies usually have a warehouse or distribution centre. Raw…

15. August 2018

The Jidoka principle in production and logistics

The Jidoka principle describes the ability of a machine, a plant or an entire system to switch…

10. July 2018

Set-up time in production and intralogistics

If a machine or a production site, i.e. individual facilities or entire production lines, is set up…

24. May 2018

Logistics management and the supply chain

The integrated planning, organization, management, processing and control of the entire flow of…

16. May 2018

Vogel’s approximation method

The approximation method according to Vogel is a heuristic procedure that is mainly used in…

6. March 2018

Opportunity costs in logistics

Opportunity costs, also known as alternative costs or foregone costs, express a foregone benefit in…

25. September 2017

Human-machine interfaces in the industry

The human-machine interface represents the analog or digital interaction interface between a…

18. September 2017

Kanban and swarm intelligence at management level

In manufacturing and industry, a supply concept called Kanban(Japanese for card or sign), invented…

18. July 2017

The control center in intralogistics

The control panel in intralogistics represents a central point of a warehouse management system and…

23. May 2017

Smart Data

Smart Data stands for the detailed and structured result of an analysis of unstructured data masses…

12. May 2017

The Supply Chain Management (SCM)

Supply chain management (SCM) stands for the monitoring process as well as the coordination and…

1. March 2017

Order picking – process steps

Picking stands for the combination of predefined orders from a warehouse assortment. The process…

9. February 2017

The storage location management

The storage location management ensures that a storage location is recorded or occupied in width,…

24. January 2017

The process-oriented warehouse planning

The process-oriented warehouse planning already takes into account in detail key positions relevant…

12. January 2017

Materials management in production and logistics

Materials management controls the material flow within a company as well as order-related material…

7. November 2016

The end of the 6 Rs of logistics? – Part 1

The tasks of logistics and the logistician are memorably explained with the famous 6 Rs. The 6 Rs…

17. October 2016

Swarm intelligence – What we logisticians can learn from ants – Part I

Surely you use a navigation system. So then you are already relying on the performance of ants and…

4. October 2016

Optimization through process chain management

Process chain management serves to organize business processes in intralogistics and other…

10. August 2016

Functions of the warehouse

When considering the functions of a warehouse, the purpose of the warehouse arrangement is in the…

17. June 2016

Ergonomics in the warehouse

Ergonomics in the warehouse aims at the adaptation and creation of workstations which, taking into…

12. May 2016

Specifications and requirement documents in intralogistics

The specification sheet generally contains the project requirements predefined and described in…

25. April 2016

Definition – WMS – The Warehouse Management System

The Warehouse Management System (WMS) is an indispensable software for the control and…

26. February 2016

Picking times – base time

In picking, the base time is the time required for picking. It only describes organisational…

10. February 2016

Material flow control as a service for a distribution center

Material flow control, also known as material flow computer or material flow control system (MFCS),…

2. February 2016

Automated guided vehicles (AGVs)

From the technical committee of the VDI (Association of German Engineers), automated guided…

28. January 2016

Cut-off time in intralogistics

In intralogistics, the cut-off time describes the time at which an order must leave the warehouse…

18. January 2016

Function and advantages of the ant algorithm

The Ant Algorithm, also often called Ant Colony Optimization (ACO) in the literature, is an…

15. January 2016

The cost of unused opportunities in supply chain management

No company can afford not to have the cost side under control. The figures from financial…

14. December 2015

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

7. December 2015

Definition – The Milk Run Concept

The milk run concept is a method for optimizing inter-company procurement logistics, often used in…

1. December 2015

The degree of utilisation/the capacity utilisation

The degree of capacity utilisation describes the proportion of the capacity used by…

2. November 2015

Definition of Accounting / Bookkeeping

The term accounting describes the comprehensive recording, storage and analysis or evaluation of…

19. October 2015

Buffer line

A buffer section is used to intercept jams within the material flow, to avoid bottlenecks and idle…

18. September 2015

Returns processing

Returns handling describes several processes in the return of goodsordered - mostly - online. They…

14. September 2015

Storage capacity/storage economy

Storage capacity is defined as the maximum number of loading units that a warehouse can hold. It…