Supply

21. January 2022

Definition of replenishment in transport and intralogistics

Replenishment is a fundamentally important process in today's enterprise resource planning. With…

16. December 2020

Definition – tugger train and tugger train systems

Tugger trains are means of transport that are used in intralogistics processes, primarily in…

7. May 2020

The Bullwhip effect

The bullwhip effect describes coordination and communication problems in multi-stage supply chains…

6. December 2018

Out-of-Stock – the gap in the shelf

Out-of-stock typically refers to a shelf space in the stationary retail trade which no longer…

15. November 2018

The production cycle

In a broader sense, a production cycle is the production process that begins with the raw materials…

31. July 2018

Point of sale systems, warehouse management and branch logistics

A cash register system, also known as a POS system, is software that documents a specific financial…

27. June 2018

The range of storage

The range of storage is a key figure which expresses the internal security of supply by own stocks…

16. May 2018

Vogel’s approximation method

The approximation method according to Vogel is a heuristic procedure that is mainly used in…

8. January 2018

CPFR – Collaborative Planning, Forecasting and Replenishment

CPFR stands for Collaborative Planning, Forecasting and Replenishment and is a further development…

1. March 2017

Order picking – process steps

Picking stands for the combination of predefined orders from a warehouse assortment. The process…

16. February 2017

The picking travel time

The order-picking way time is the sum of the time required for picking a single order or batch;…

10. August 2016

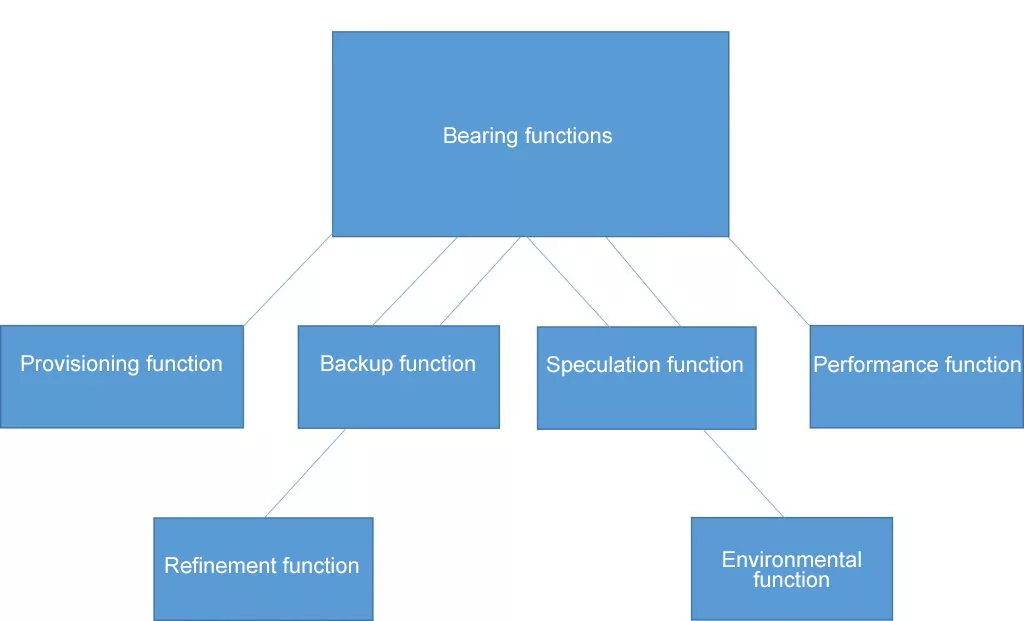

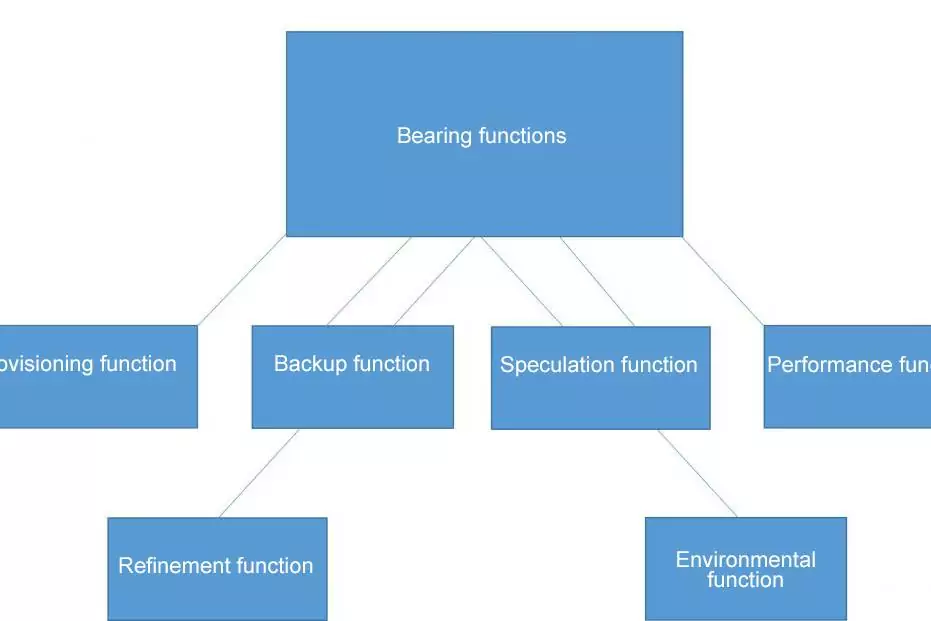

Functions of the warehouse

When considering the functions of a warehouse, the purpose of the warehouse arrangement is in the…

23. March 2016

What can logistics accomplish?

In recent decades, the term "logistics" has developed into a general term. This is a good thing.…

14. December 2015

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

1. December 2015

The degree of utilisation/the capacity utilisation

The degree of capacity utilisation describes the proportion of the capacity used by…

14. September 2015

Storage capacity/storage economy

Storage capacity is defined as the maximum number of loading units that a warehouse can hold. It…

22. July 2015

Heijunka lean method

The Japanese lean method Heijunka pushes a production where the production flow of the parts market…

10. July 2015

Assortment width and assortment depth

The assortment available in a warehouse and in the retail trade is subdivided into the assortment…

3. February 2014

Storage and retrieval machine

A storage and retrieval machine (SRM) is a storage device with which load units can be stored,…

3. December 2013

Definition – Transshipment logistics

Goods handling is a function of intralogistics and takes place between the external goods flow and…

14. November 2013

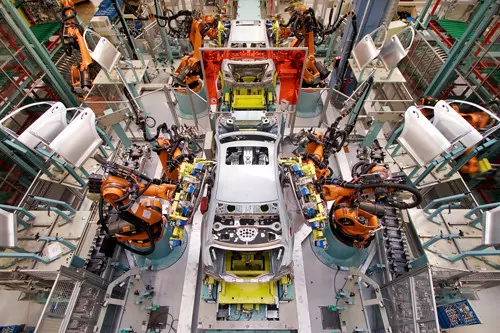

Overview of common manufacturing principles

Different principles can be applied in manufacturing. Some products are manufactured according to…

9. September 2013

Transport strategies: Overview

Transport strategies are used to execute existing transport orders. Transportation strategies can…

3. September 2013

Continuous conveyor / discontinuous conveyor

Both the continuous conveyor and the discontinuous conveyor belong to the conveyor technology…

15. July 2013

Kanban system

The Kanban system is a planning system for production control. the Kanban system is often split…

15. July 2013

Cross-docking

There are different types of handling goods in the shipping area. One of these is called…

15. July 2013

Just-in-time – Definition

“Just-in-time” refers to a type of delivery in which the required goods are delivered…

15. July 2013

Procurement logistics – Just in sequence

"Just in sequence" refers to a type of delivery in which the required goods are delivered to the…

15. July 2013

Overview of goods-to-person picking

Goods-to-person picking (also: goods-to-man picking) describes a picking method in which the…

21. January 2022

Definition of replenishment in transport and intralogistics

Replenishment is a fundamentally important process in today's enterprise resource planning. With…

16. December 2020

Definition – tugger train and tugger train systems

Tugger trains are means of transport that are used in intralogistics processes, primarily in…

7. May 2020

The Bullwhip effect

The bullwhip effect describes coordination and communication problems in multi-stage supply chains…

6. December 2018

Out-of-Stock – the gap in the shelf

Out-of-stock typically refers to a shelf space in the stationary retail trade which no longer…

15. November 2018

The production cycle

In a broader sense, a production cycle is the production process that begins with the raw materials…

31. July 2018

Point of sale systems, warehouse management and branch logistics

A cash register system, also known as a POS system, is software that documents a specific financial…

27. June 2018

The range of storage

The range of storage is a key figure which expresses the internal security of supply by own stocks…

16. May 2018

Vogel’s approximation method

The approximation method according to Vogel is a heuristic procedure that is mainly used in…

8. January 2018

CPFR – Collaborative Planning, Forecasting and Replenishment

CPFR stands for Collaborative Planning, Forecasting and Replenishment and is a further development…

1. March 2017

Order picking – process steps

Picking stands for the combination of predefined orders from a warehouse assortment. The process…

16. February 2017

The picking travel time

The order-picking way time is the sum of the time required for picking a single order or batch;…

10. August 2016

Functions of the warehouse

When considering the functions of a warehouse, the purpose of the warehouse arrangement is in the…

23. March 2016

What can logistics accomplish?

In recent decades, the term "logistics" has developed into a general term. This is a good thing.…

14. December 2015

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

1. December 2015

The degree of utilisation/the capacity utilisation

The degree of capacity utilisation describes the proportion of the capacity used by…

14. September 2015

Storage capacity/storage economy

Storage capacity is defined as the maximum number of loading units that a warehouse can hold. It…

22. July 2015

Heijunka lean method

The Japanese lean method Heijunka pushes a production where the production flow of the parts market…

10. July 2015

Assortment width and assortment depth

The assortment available in a warehouse and in the retail trade is subdivided into the assortment…

3. February 2014

Storage and retrieval machine

A storage and retrieval machine (SRM) is a storage device with which load units can be stored,…

3. December 2013

Definition – Transshipment logistics

Goods handling is a function of intralogistics and takes place between the external goods flow and…

14. November 2013

Overview of common manufacturing principles

Different principles can be applied in manufacturing. Some products are manufactured according to…

9. September 2013

Transport strategies: Overview

Transport strategies are used to execute existing transport orders. Transportation strategies can…

3. September 2013

Continuous conveyor / discontinuous conveyor

Both the continuous conveyor and the discontinuous conveyor belong to the conveyor technology…

15. July 2013

Kanban system

The Kanban system is a planning system for production control. the Kanban system is often split…

15. July 2013

Cross-docking

There are different types of handling goods in the shipping area. One of these is called…

15. July 2013

Just-in-time – Definition

“Just-in-time” refers to a type of delivery in which the required goods are delivered…

15. July 2013

Procurement logistics – Just in sequence

"Just in sequence" refers to a type of delivery in which the required goods are delivered to the…

15. July 2013

Overview of goods-to-person picking

Goods-to-person picking (also: goods-to-man picking) describes a picking method in which the…