Material flow and transport

26. September 2023

AutoStore: Storage technology from Norway

AutoStore is a Norwegian storage technology and, according to the company of the same name, is…

8. September 2023

Advance Shipping Notice

An Advance Shipping Notice (ASN), also advice note or avis, is a piece of preliminary information…

28. December 2022

Industrial trucks – definition, function and variants

Industrial trucks, also known as ground conveyors or floor conveyors, are vehicles used to…

14. April 2022

Advantages and definition of the transhipment type cross docking

There are various handling methods for inventory in the shipping area. One of these handling…

21. January 2022

Definition of replenishment in transport and intralogistics

Replenishment is a fundamentally important process in today's enterprise resource planning. With…

7. September 2021

Overview of VDA 5050 – the VDA communication interface for AGVs

VDA 5050 is the definition of a communication interface for Driverless Transport Systems. Currently…

6. August 2021

Regulations and labeling for the transport of dangerous goods by truck

Around the world, hazardous goods are transported every day. For Germany alone, the total volume…

20. April 2021

Definition and overview of the logistic process shipping and the common shipping types

What is included in the business process of shipping?The transport of goods from a company’s…

24. February 2021

Overview of the term logistics – definitions, specializations and job descriptions

Table of contents Introduction Logistics definition and the 6 R Areas in logistics Processes in…

16. December 2020

Definition – tugger train and tugger train systems

Tugger trains are means of transport that are used in intralogistics processes, primarily in…

7. May 2020

Single-stage picking – order-oriented, parallel picking

With parallel picking, an order is divided between different picking zones and processed…

7. May 2020

The Bullwhip effect

The bullwhip effect describes coordination and communication problems in multi-stage supply chains…

1. April 2020

Turnover rate and Rotation of goods: Fast and slow movers

The inventory turnover, also known as the inventory turnover rate or inventory turnover…

13. January 2020

Movement strategies within warehouse operations

The aim of utilising movement strategies is to adhere to specified guidelines in warehouse…

24. April 2019

Production, dispatch and intralogistics: the rush order

A rush order is an order - in production, shipping or in intralogistics - which for various reasons…

21. March 2019

The packaging logistics

Packaging logistics is a sub-area of logistics; it is a link between production and distribution.…

6. February 2019

Advantages and disadvantages: centralized and decentralized warehouse

In distribution logistics, the determination of warehouse locations represents a strategic…

16. October 2018

Insulated packaging: Maintaining the cold chain in the supply chain

Insulated packaging is used for products that are sensitive to temperature or environmental…

20. June 2018

Cyber-physical systems and logistics

Cyber-physical systems, or CPS for short, are system units or components that are linked together…

24. May 2018

Logistics management and the supply chain

The integrated planning, organization, management, processing and control of the entire flow of…

16. May 2018

Vogel’s approximation method

The approximation method according to Vogel is a heuristic procedure that is mainly used in…

19. April 2018

The screw conveyor / spiral conveyor for bulk material

Transport systems are needed in warehouses to transport goods. For this purpose, there are various…

24. October 2017

Picking method Pick-by-robot

The picking type Pick-by-Robot means the picking of goods, carried out by so-called…

16. October 2017

Multicopter: Drones as parcel carriers of the future

Goods delivery by automated or even autonomous drones? What we know at best as a vision from…

8. May 2017

Logistics – Definition

The term logistics stands for the planning, control and monitoring of the material and immaterial…

18. April 2017

Effects of shipping options on loyalty to the online store

Buying on the Internet offers almost endless possibilities and shipping options. Whether books,…

30. March 2017

Conveying aids in intralogistics

In intralogistics, conveying equipment is used to combine individual goods into larger load units.…

22. March 2017

Order picking times – Dead time

Dead time is an unproductive but unavoidable so-called auxiliary time, which arises during picking…

9. March 2017

The (hanging) bag sorter

The Pouch sorter / Bag sorter belongs to the category of logistic sorting and distribution systems.…

16. February 2017

The picking travel time

The order-picking way time is the sum of the time required for picking a single order or batch;…

9. February 2017

The storage location management

The storage location management ensures that a storage location is recorded or occupied in width,…

27. January 2017

Overloading of trucks – dangers and fines

A wide variety of goods are transported on Germany's roads every day. According to the Federal…

19. January 2017

Last-mile logistics in e-commerce – challenges and solutions

Online commerce has shown considerable growth in the past decades. The B2C sector in particular…

17. October 2016

Swarm intelligence – What we logisticians can learn from ants – Part I

Surely you use a navigation system. So then you are already relying on the performance of ants and…

25. April 2016

Definition – WMS – The Warehouse Management System

The Warehouse Management System (WMS) is an indispensable software for the control and…

7. April 2016

CMR: the consignment note

The term CMR comes from the French, Convention relative au Contrat de transport international de…

23. March 2016

What can logistics accomplish?

In recent decades, the term "logistics" has developed into a general term. This is a good thing.…

10. February 2016

Material flow control as a service for a distribution center

Material flow control, also known as material flow computer or material flow control system (MFCS),…

2. February 2016

Automated guided vehicles (AGVs)

From the technical committee of the VDI (Association of German Engineers), automated guided…

28. January 2016

Cut-off time in intralogistics

In intralogistics, the cut-off time describes the time at which an order must leave the warehouse…

26. January 2016

The Newsvendor Model in SCM

Many supply chain management (SCM) approaches can be explained using the Newsvendor Model (NVM).…

18. January 2016

Function and advantages of the ant algorithm

The Ant Algorithm, also often called Ant Colony Optimization (ACO) in the literature, is an…

15. January 2016

The cost of unused opportunities in supply chain management

No company can afford not to have the cost side under control. The figures from financial…

14. December 2015

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

7. December 2015

Definition – The Milk Run Concept

The milk run concept is a method for optimizing inter-company procurement logistics, often used in…

19. October 2015

Buffer line

A buffer section is used to intercept jams within the material flow, to avoid bottlenecks and idle…

21. September 2015

Information in intralogistics

Information describes the meaningful content of a message, which is of value for the recipient. The…

18. September 2015

Returns processing

Returns handling describes several processes in the return of goodsordered - mostly - online. They…

22. July 2015

Heijunka lean method

The Japanese lean method Heijunka pushes a production where the production flow of the parts market…

6. July 2015

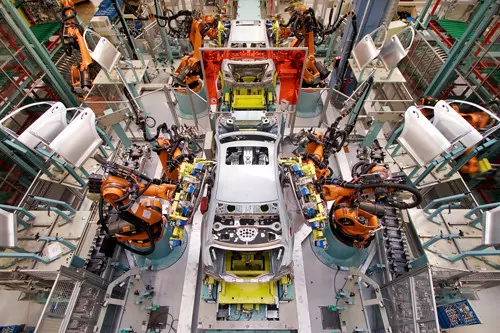

Modularization of materials handling equipment – approach to a standardized system architecture

The current market development shows the following challenges: New component technologies require…

- 1

- 2

26. September 2023

AutoStore: Storage technology from Norway

AutoStore is a Norwegian storage technology and, according to the company of the same name, is…

8. September 2023

Advance Shipping Notice

An Advance Shipping Notice (ASN), also advice note or avis, is a piece of preliminary information…

28. December 2022

Industrial trucks – definition, function and variants

Industrial trucks, also known as ground conveyors or floor conveyors, are vehicles used to…

14. April 2022

Advantages and definition of the transhipment type cross docking

There are various handling methods for inventory in the shipping area. One of these handling…

21. January 2022

Definition of replenishment in transport and intralogistics

Replenishment is a fundamentally important process in today's enterprise resource planning. With…

7. September 2021

Overview of VDA 5050 – the VDA communication interface for AGVs

VDA 5050 is the definition of a communication interface for Driverless Transport Systems. Currently…

6. August 2021

Regulations and labeling for the transport of dangerous goods by truck

Around the world, hazardous goods are transported every day. For Germany alone, the total volume…

20. April 2021

Definition and overview of the logistic process shipping and the common shipping types

What is included in the business process of shipping?The transport of goods from a company’s…

24. February 2021

Overview of the term logistics – definitions, specializations and job descriptions

Table of contents Introduction Logistics definition and the 6 R Areas in logistics Processes in…

16. December 2020

Definition – tugger train and tugger train systems

Tugger trains are means of transport that are used in intralogistics processes, primarily in…

7. May 2020

Single-stage picking – order-oriented, parallel picking

With parallel picking, an order is divided between different picking zones and processed…

7. May 2020

The Bullwhip effect

The bullwhip effect describes coordination and communication problems in multi-stage supply chains…

1. April 2020

Turnover rate and Rotation of goods: Fast and slow movers

The inventory turnover, also known as the inventory turnover rate or inventory turnover…

13. January 2020

Movement strategies within warehouse operations

The aim of utilising movement strategies is to adhere to specified guidelines in warehouse…

24. April 2019

Production, dispatch and intralogistics: the rush order

A rush order is an order - in production, shipping or in intralogistics - which for various reasons…

21. March 2019

The packaging logistics

Packaging logistics is a sub-area of logistics; it is a link between production and distribution.…

6. February 2019

Advantages and disadvantages: centralized and decentralized warehouse

In distribution logistics, the determination of warehouse locations represents a strategic…

16. October 2018

Insulated packaging: Maintaining the cold chain in the supply chain

Insulated packaging is used for products that are sensitive to temperature or environmental…

20. June 2018

Cyber-physical systems and logistics

Cyber-physical systems, or CPS for short, are system units or components that are linked together…

24. May 2018

Logistics management and the supply chain

The integrated planning, organization, management, processing and control of the entire flow of…

16. May 2018

Vogel’s approximation method

The approximation method according to Vogel is a heuristic procedure that is mainly used in…

19. April 2018

The screw conveyor / spiral conveyor for bulk material

Transport systems are needed in warehouses to transport goods. For this purpose, there are various…

24. October 2017

Picking method Pick-by-robot

The picking type Pick-by-Robot means the picking of goods, carried out by so-called…

16. October 2017

Multicopter: Drones as parcel carriers of the future

Goods delivery by automated or even autonomous drones? What we know at best as a vision from…

8. May 2017

Logistics – Definition

The term logistics stands for the planning, control and monitoring of the material and immaterial…

18. April 2017

Effects of shipping options on loyalty to the online store

Buying on the Internet offers almost endless possibilities and shipping options. Whether books,…

30. March 2017

Conveying aids in intralogistics

In intralogistics, conveying equipment is used to combine individual goods into larger load units.…

22. March 2017

Order picking times – Dead time

Dead time is an unproductive but unavoidable so-called auxiliary time, which arises during picking…

9. March 2017

The (hanging) bag sorter

The Pouch sorter / Bag sorter belongs to the category of logistic sorting and distribution systems.…

16. February 2017

The picking travel time

The order-picking way time is the sum of the time required for picking a single order or batch;…

9. February 2017

The storage location management

The storage location management ensures that a storage location is recorded or occupied in width,…

27. January 2017

Overloading of trucks – dangers and fines

A wide variety of goods are transported on Germany's roads every day. According to the Federal…

19. January 2017

Last-mile logistics in e-commerce – challenges and solutions

Online commerce has shown considerable growth in the past decades. The B2C sector in particular…

17. October 2016

Swarm intelligence – What we logisticians can learn from ants – Part I

Surely you use a navigation system. So then you are already relying on the performance of ants and…

25. April 2016

Definition – WMS – The Warehouse Management System

The Warehouse Management System (WMS) is an indispensable software for the control and…

7. April 2016

CMR: the consignment note

The term CMR comes from the French, Convention relative au Contrat de transport international de…

23. March 2016

What can logistics accomplish?

In recent decades, the term "logistics" has developed into a general term. This is a good thing.…

10. February 2016

Material flow control as a service for a distribution center

Material flow control, also known as material flow computer or material flow control system (MFCS),…

2. February 2016

Automated guided vehicles (AGVs)

From the technical committee of the VDI (Association of German Engineers), automated guided…

28. January 2016

Cut-off time in intralogistics

In intralogistics, the cut-off time describes the time at which an order must leave the warehouse…

26. January 2016

The Newsvendor Model in SCM

Many supply chain management (SCM) approaches can be explained using the Newsvendor Model (NVM).…

18. January 2016

Function and advantages of the ant algorithm

The Ant Algorithm, also often called Ant Colony Optimization (ACO) in the literature, is an…

15. January 2016

The cost of unused opportunities in supply chain management

No company can afford not to have the cost side under control. The figures from financial…

14. December 2015

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

7. December 2015

Definition – The Milk Run Concept

The milk run concept is a method for optimizing inter-company procurement logistics, often used in…

19. October 2015

Buffer line

A buffer section is used to intercept jams within the material flow, to avoid bottlenecks and idle…

21. September 2015

Information in intralogistics

Information describes the meaningful content of a message, which is of value for the recipient. The…

18. September 2015

Returns processing

Returns handling describes several processes in the return of goodsordered - mostly - online. They…

22. July 2015

Heijunka lean method

The Japanese lean method Heijunka pushes a production where the production flow of the parts market…

6. July 2015

Modularization of materials handling equipment – approach to a standardized system architecture

The current market development shows the following challenges: New component technologies require…