Warehouse automation

26. September 2023

AutoStore: Storage technology from Norway

AutoStore is a Norwegian storage technology and, according to the company of the same name, is…

7. May 2020

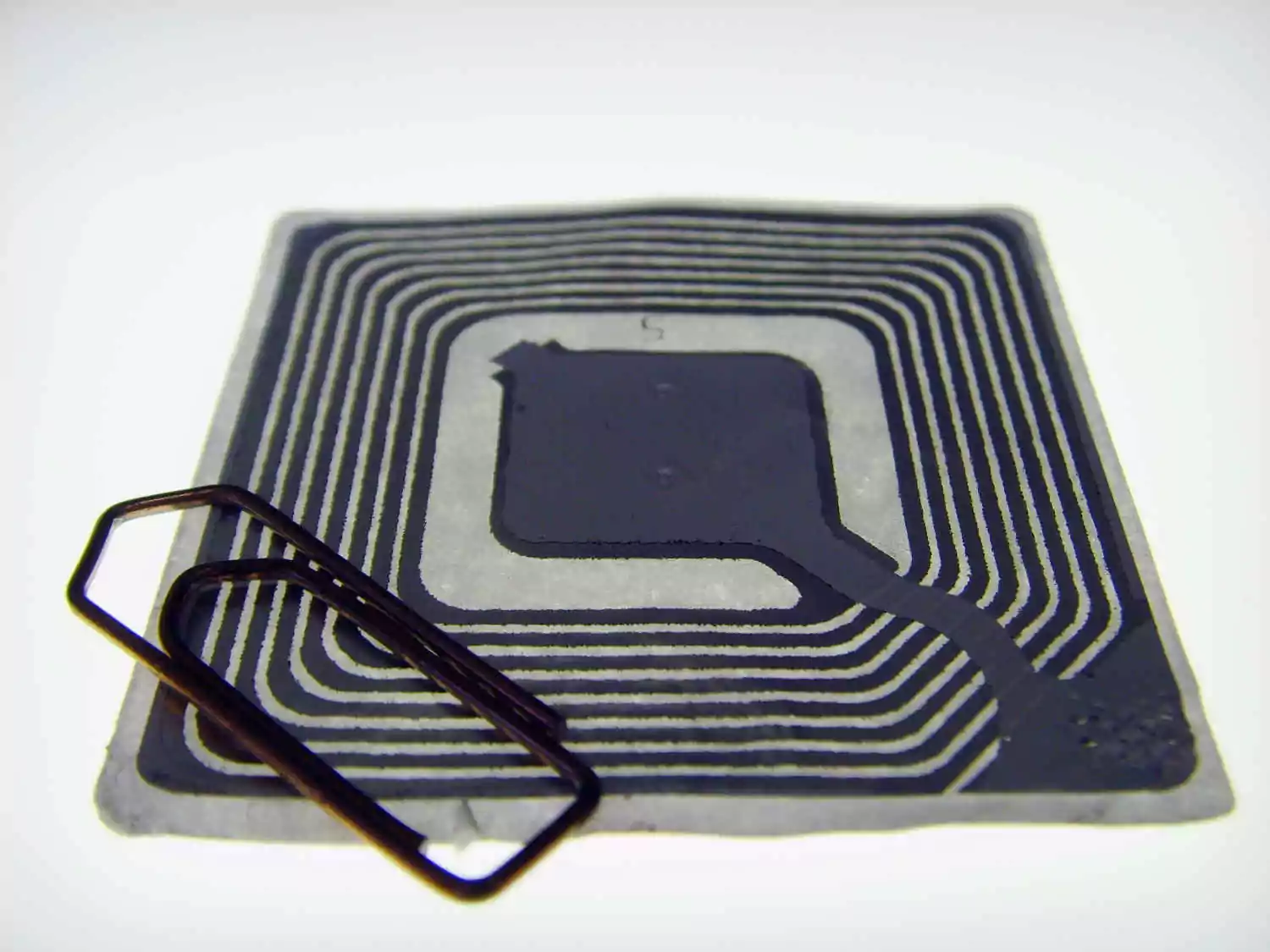

Radio Frequency Identification (RFID)

Radio Frequency Identification (RFID) is a technology for the unambiguous and contact-free…

8. October 2019

Swarm intelligence – What we logisticians can learn from ants – Part II

You may think estimating the weight of an ox, as described in Part 1 of this article, is hardly a…

13. June 2019

The Internet of Things (IoT) and intralogistics

The Internet of Things (IoT) describes the networking of physical objects (fitness bracelets, smart…

3. May 2019

SAIL – the system architecture for intralogistics from VDI / VDMA

"Innovation and Standardization" is the title of a working group of the Intralogistics Forum of the…

21. March 2019

The packaging logistics

Packaging logistics is a sub-area of logistics; it is a link between production and distribution.…

14. February 2019

Two-dimensional codes: stacked codes, matrix codes, QR code, DataMatrix code

The one-dimensional bar code is commonly used to label goods and services. However, since the data…

6. February 2019

Advantages and disadvantages: centralized and decentralized warehouse

In distribution logistics, the determination of warehouse locations represents a strategic…

15. November 2018

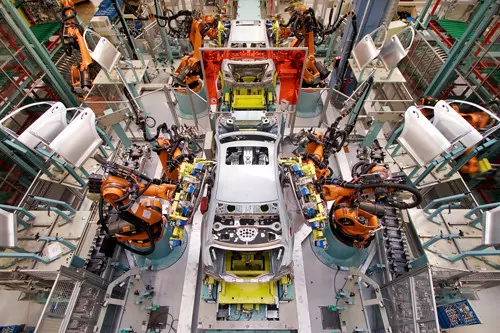

The production cycle

In a broader sense, a production cycle is the production process that begins with the raw materials…

7. November 2018

Inventory in companies and in logistics

In the inventory, the assets of a company are determined on a key date; in this way, assets and…

28. September 2018

Uses of Blockchain technology in logistics / intralogistics

Blockchain is an enabling technology. Just like the Internet, it harbors technological properties…

15. August 2018

The Jidoka principle in production and logistics

The Jidoka principle describes the ability of a machine, a plant or an entire system to switch…

10. July 2018

Set-up time in production and intralogistics

If a machine or a production site, i.e. individual facilities or entire production lines, is set up…

16. May 2018

Vogel’s approximation method

The approximation method according to Vogel is a heuristic procedure that is mainly used in…

8. January 2018

CPFR – Collaborative Planning, Forecasting and Replenishment

CPFR stands for Collaborative Planning, Forecasting and Replenishment and is a further development…

14. November 2017

The picking time in intralogistics

The picking process itself and the associated picking time are usually a conglomerate of personnel-…

24. October 2017

Picking method Pick-by-robot

The picking type Pick-by-Robot means the picking of goods, carried out by so-called…

25. September 2017

Human-machine interfaces in the industry

The human-machine interface represents the analog or digital interaction interface between a…

12. September 2017

The picking method Pick-by-Vision

Pick-by-Vision is a picking process in which a picker uses data glasses and context-related…

19. June 2017

Augmented Reality in logistics and service

Augmented Reality (AR) describes the computer-aided extension of human perception of reality. From…

18. April 2017

Key figure system in intralogistics

Although a complete bundling of all key figures arising in warehouse and distribution systems is…

9. March 2017

The (hanging) bag sorter

The Pouch sorter / Bag sorter belongs to the category of logistic sorting and distribution systems.…

16. February 2017

The picking travel time

The order-picking way time is the sum of the time required for picking a single order or batch;…

9. February 2017

The storage location management

The storage location management ensures that a storage location is recorded or occupied in width,…

24. January 2017

The process-oriented warehouse planning

The process-oriented warehouse planning already takes into account in detail key positions relevant…

17. October 2016

Swarm intelligence – What we logisticians can learn from ants – Part I

Surely you use a navigation system. So then you are already relying on the performance of ants and…

4. October 2016

Optimization through process chain management

Process chain management serves to organize business processes in intralogistics and other…

17. June 2016

Ergonomics in the warehouse

Ergonomics in the warehouse aims at the adaptation and creation of workstations which, taking into…

25. April 2016

Definition – WMS – The Warehouse Management System

The Warehouse Management System (WMS) is an indispensable software for the control and…

10. February 2016

Material flow control as a service for a distribution center

Material flow control, also known as material flow computer or material flow control system (MFCS),…

2. February 2016

Automated guided vehicles (AGVs)

From the technical committee of the VDI (Association of German Engineers), automated guided…

28. January 2016

Cut-off time in intralogistics

In intralogistics, the cut-off time describes the time at which an order must leave the warehouse…

18. January 2016

Function and advantages of the ant algorithm

The Ant Algorithm, also often called Ant Colony Optimization (ACO) in the literature, is an…

14. December 2015

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

19. October 2015

Buffer line

A buffer section is used to intercept jams within the material flow, to avoid bottlenecks and idle…

21. September 2015

Information in intralogistics

Information describes the meaningful content of a message, which is of value for the recipient. The…

22. July 2015

Heijunka lean method

The Japanese lean method Heijunka pushes a production where the production flow of the parts market…

14. April 2015

The distribution center

A distribution center is an interface in the form of a building complex that functions exclusively…

3. February 2014

Storage and retrieval machine

A storage and retrieval machine (SRM) is a storage device with which load units can be stored,…

3. September 2013

Continuous conveyor / discontinuous conveyor

Both the continuous conveyor and the discontinuous conveyor belong to the conveyor technology…

10. July 2013

The importance of material flow

According to VDI, "material flow" is the interlinking of all processes involved in extracting,…

26. September 2023

AutoStore: Storage technology from Norway

AutoStore is a Norwegian storage technology and, according to the company of the same name, is…

7. May 2020

Radio Frequency Identification (RFID)

Radio Frequency Identification (RFID) is a technology for the unambiguous and contact-free…

8. October 2019

Swarm intelligence – What we logisticians can learn from ants – Part II

You may think estimating the weight of an ox, as described in Part 1 of this article, is hardly a…

13. June 2019

The Internet of Things (IoT) and intralogistics

The Internet of Things (IoT) describes the networking of physical objects (fitness bracelets, smart…

3. May 2019

SAIL – the system architecture for intralogistics from VDI / VDMA

"Innovation and Standardization" is the title of a working group of the Intralogistics Forum of the…

21. March 2019

The packaging logistics

Packaging logistics is a sub-area of logistics; it is a link between production and distribution.…

14. February 2019

Two-dimensional codes: stacked codes, matrix codes, QR code, DataMatrix code

The one-dimensional bar code is commonly used to label goods and services. However, since the data…

6. February 2019

Advantages and disadvantages: centralized and decentralized warehouse

In distribution logistics, the determination of warehouse locations represents a strategic…

15. November 2018

The production cycle

In a broader sense, a production cycle is the production process that begins with the raw materials…

7. November 2018

Inventory in companies and in logistics

In the inventory, the assets of a company are determined on a key date; in this way, assets and…

28. September 2018

Uses of Blockchain technology in logistics / intralogistics

Blockchain is an enabling technology. Just like the Internet, it harbors technological properties…

15. August 2018

The Jidoka principle in production and logistics

The Jidoka principle describes the ability of a machine, a plant or an entire system to switch…

10. July 2018

Set-up time in production and intralogistics

If a machine or a production site, i.e. individual facilities or entire production lines, is set up…

16. May 2018

Vogel’s approximation method

The approximation method according to Vogel is a heuristic procedure that is mainly used in…

8. January 2018

CPFR – Collaborative Planning, Forecasting and Replenishment

CPFR stands for Collaborative Planning, Forecasting and Replenishment and is a further development…

14. November 2017

The picking time in intralogistics

The picking process itself and the associated picking time are usually a conglomerate of personnel-…

24. October 2017

Picking method Pick-by-robot

The picking type Pick-by-Robot means the picking of goods, carried out by so-called…

25. September 2017

Human-machine interfaces in the industry

The human-machine interface represents the analog or digital interaction interface between a…

12. September 2017

The picking method Pick-by-Vision

Pick-by-Vision is a picking process in which a picker uses data glasses and context-related…

19. June 2017

Augmented Reality in logistics and service

Augmented Reality (AR) describes the computer-aided extension of human perception of reality. From…

18. April 2017

Key figure system in intralogistics

Although a complete bundling of all key figures arising in warehouse and distribution systems is…

9. March 2017

The (hanging) bag sorter

The Pouch sorter / Bag sorter belongs to the category of logistic sorting and distribution systems.…

16. February 2017

The picking travel time

The order-picking way time is the sum of the time required for picking a single order or batch;…

9. February 2017

The storage location management

The storage location management ensures that a storage location is recorded or occupied in width,…

24. January 2017

The process-oriented warehouse planning

The process-oriented warehouse planning already takes into account in detail key positions relevant…

17. October 2016

Swarm intelligence – What we logisticians can learn from ants – Part I

Surely you use a navigation system. So then you are already relying on the performance of ants and…

4. October 2016

Optimization through process chain management

Process chain management serves to organize business processes in intralogistics and other…

17. June 2016

Ergonomics in the warehouse

Ergonomics in the warehouse aims at the adaptation and creation of workstations which, taking into…

25. April 2016

Definition – WMS – The Warehouse Management System

The Warehouse Management System (WMS) is an indispensable software for the control and…

10. February 2016

Material flow control as a service for a distribution center

Material flow control, also known as material flow computer or material flow control system (MFCS),…

2. February 2016

Automated guided vehicles (AGVs)

From the technical committee of the VDI (Association of German Engineers), automated guided…

28. January 2016

Cut-off time in intralogistics

In intralogistics, the cut-off time describes the time at which an order must leave the warehouse…

18. January 2016

Function and advantages of the ant algorithm

The Ant Algorithm, also often called Ant Colony Optimization (ACO) in the literature, is an…

14. December 2015

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

19. October 2015

Buffer line

A buffer section is used to intercept jams within the material flow, to avoid bottlenecks and idle…

21. September 2015

Information in intralogistics

Information describes the meaningful content of a message, which is of value for the recipient. The…

22. July 2015

Heijunka lean method

The Japanese lean method Heijunka pushes a production where the production flow of the parts market…

14. April 2015

The distribution center

A distribution center is an interface in the form of a building complex that functions exclusively…

3. February 2014

Storage and retrieval machine

A storage and retrieval machine (SRM) is a storage device with which load units can be stored,…

3. September 2013

Continuous conveyor / discontinuous conveyor

Both the continuous conveyor and the discontinuous conveyor belong to the conveyor technology…

10. July 2013

The importance of material flow

According to VDI, "material flow" is the interlinking of all processes involved in extracting,…