Materials management controls the material flow within a company as well as order-related material flows to customers and suppliers. As a rule, the focus is on the business management and thus commercial aspects. Seen from above, it links all the commercial and technical infrastructures of a company that affect the flow of goods in terms of time, quantity, quality and space.

The central tasks of materials management are to plan and control the flow of goods between the company, suppliers and ultimately the customer. This also includes internal recipients or senders. The internal stakeholders are, for example, the various departments within large companies as well as the associated branch offices and subsidiaries (warehouse, production, sales). Materials management should not be confused with production management or production logistics.

Value chain always in focus

In professional circles, it is regarded as a central starting point from which the entire value chain can be controlled. This is based on three different target types. The material goals, formal goals, and environmental goals are closely interlinked.

- Material goals are usually targets with which formal goals can be achieved. They are of an economic nature and ultimately stand for the turnover and profit of a company. As an example: Goods or materials are only made available in the required quantity. Storage location (transport costs), storage costs (storage economy) and product price are decisive and interdependent success factors.

- The social objectives are commonly based on environmental protection and are therefore also considered to be of high social value. On the one hand, companies in Europe are obliged to comply with legal guidelines and regulations regarding recycling and disposal; on the other hand, it has become part of their reputation management to practice environmentally friendly and thus low-emission materials management (lean production).

But energy efficiency is also an integral part of materials management these days, ensuring the aforementioned environmentally friendly image and at the same time promoting a positive formal goal. These social objectives are usually supported by the state.

In materials management, two distinct segments exist:

- Production: In manufacturing companies, materials management focuses on all aspects of controlling and planning the flow of raw materials and supplies.

- Distribution: Distribution, on the other hand, relies on defined sales channels and direct contact with the end customer (multi-channel, omnichannel, stationary trade) for its logistical execution via distribution centers. In contrast to production, finished products are sold.

Nevertheless, there is no uniform definition of materials management. The areas of responsibility of the various companies or service providers are too different. In general, the following may apply:

The continuous flow of materials means that necessary materials must be available in a certain qualitatively perfect quantity at the right place and at the right time; for example, the Milk run concept. This also includes office supplies, which are needed for order processing.

Materials management summarized

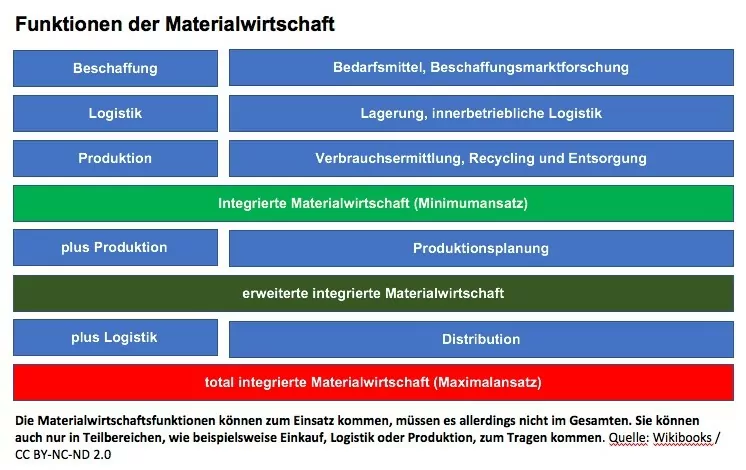

Materials management deals with the planning and control of material flows within companies and with those of externally networked branch offices and participating suppliers. The formal goal of achieving profit has priority in the end. Depending on how it is viewed, Materials Management takes on tasks in the sub-areas of procurement, production, logistics and intralogistics.

For more information on materials management, see also the Logistics definition and Inventory Management.

Teaser image: Wollschlägergruppe / CC BY-SA 3.0

Also available in Deutsch (German)