Storage techniques

31. May 2024

What is warehousing? Overview and definition

In German, the English term “warehousing” is increasingly being used, which is in it…

26. September 2023

AutoStore: Storage technology from Norway

AutoStore is a Norwegian storage technology and, according to the company of the same name, is…

15. November 2021

Microfulfillment – definition and overview

Microfulfillment describes the decentralized and also customer-oriented execution of processes such…

7. July 2020

Rack zones – Overview

A storage rack, both in intralogistics and retail, can be divided into different horizontal racking…

25. November 2019

Allocation strategies for warehouse and picking systems/warehouse operation strategies

In a company, it is vital to set goals before developing strategies and to monitor their…

28. October 2019

Storage techniques in intralogistics

Depending on the nature of the stored goods and the frequency of use, different storage techniques…

6. February 2019

Advantages and disadvantages: centralized and decentralized warehouse

In distribution logistics, the determination of warehouse locations represents a strategic…

16. October 2018

Insulated packaging: Maintaining the cold chain in the supply chain

Insulated packaging is used for products that are sensitive to temperature or environmental…

9. March 2017

The (hanging) bag sorter

The Pouch sorter / Bag sorter belongs to the category of logistic sorting and distribution systems.…

1. March 2017

Order picking – process steps

Picking stands for the combination of predefined orders from a warehouse assortment. The process…

9. February 2017

The storage location management

The storage location management ensures that a storage location is recorded or occupied in width,…

4. October 2016

Optimization through process chain management

Process chain management serves to organize business processes in intralogistics and other…

10. August 2016

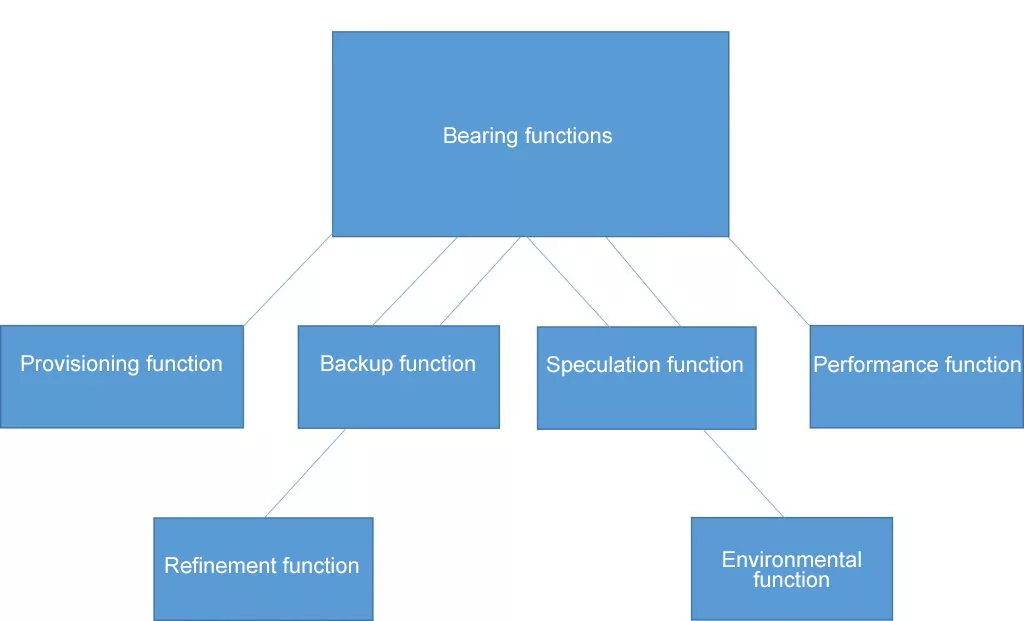

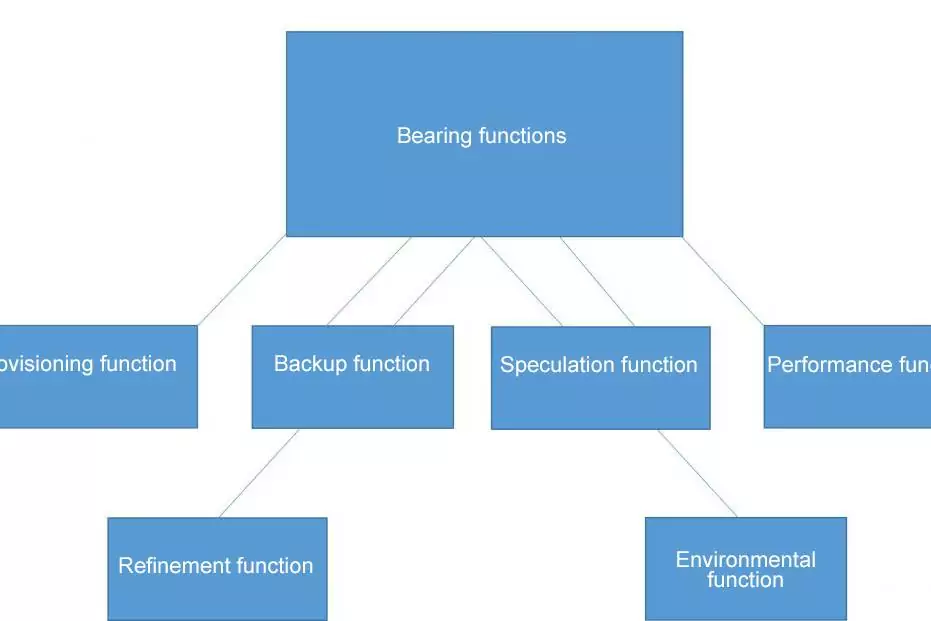

Functions of the warehouse

When considering the functions of a warehouse, the purpose of the warehouse arrangement is in the…

12. May 2016

Specifications and requirement documents in intralogistics

The specification sheet generally contains the project requirements predefined and described in…

17. September 2013

Mobile and stationary loading units

Loading units are collections of goods that are transported, transhipped or stored as they pass…

15. July 2013

Overview of “Last-in-First-out” and “First-in-First-out” storage strategies

LIFO (last-in-first-out) and FIFO (first-in-first-out) are two different strategies for storing and…

15. July 2013

Definition – Automated Storage and Retrieval System

An "Automated Storage and Retrieval System" (short: AS/RS, sometimes also "Automated small parts…

15. July 2013

Rack zones – bending zone

A rack can be divided into vertical zones based on the scale of an adult (average size of 1.70 m).…

15. July 2013

Rack zones – gripping zone

A rack can be divided into vertical zones based on the scale of an adult (average size of 1.70 m).…

15. July 2013

Rack zones – viewing zone

A rack can be divided into vertical rack based on the scale of an adult (average size of 1.70 m).…

24. June 2013

Application of a storage location management solution

With a growing warehouse, usually not only the number of articles increases, but often a dynamic in…

24. June 2013

External storage

In the case of external storage, storage takes place outside the company. The counterpart is the…

31. May 2024

What is warehousing? Overview and definition

In German, the English term “warehousing” is increasingly being used, which is in it…

26. September 2023

AutoStore: Storage technology from Norway

AutoStore is a Norwegian storage technology and, according to the company of the same name, is…

15. November 2021

Microfulfillment – definition and overview

Microfulfillment describes the decentralized and also customer-oriented execution of processes such…

7. July 2020

Rack zones – Overview

A storage rack, both in intralogistics and retail, can be divided into different horizontal racking…

25. November 2019

Allocation strategies for warehouse and picking systems/warehouse operation strategies

In a company, it is vital to set goals before developing strategies and to monitor their…

28. October 2019

Storage techniques in intralogistics

Depending on the nature of the stored goods and the frequency of use, different storage techniques…

6. February 2019

Advantages and disadvantages: centralized and decentralized warehouse

In distribution logistics, the determination of warehouse locations represents a strategic…

16. October 2018

Insulated packaging: Maintaining the cold chain in the supply chain

Insulated packaging is used for products that are sensitive to temperature or environmental…

9. March 2017

The (hanging) bag sorter

The Pouch sorter / Bag sorter belongs to the category of logistic sorting and distribution systems.…

1. March 2017

Order picking – process steps

Picking stands for the combination of predefined orders from a warehouse assortment. The process…

9. February 2017

The storage location management

The storage location management ensures that a storage location is recorded or occupied in width,…

4. October 2016

Optimization through process chain management

Process chain management serves to organize business processes in intralogistics and other…

10. August 2016

Functions of the warehouse

When considering the functions of a warehouse, the purpose of the warehouse arrangement is in the…

12. May 2016

Specifications and requirement documents in intralogistics

The specification sheet generally contains the project requirements predefined and described in…

17. September 2013

Mobile and stationary loading units

Loading units are collections of goods that are transported, transhipped or stored as they pass…

15. July 2013

Overview of “Last-in-First-out” and “First-in-First-out” storage strategies

LIFO (last-in-first-out) and FIFO (first-in-first-out) are two different strategies for storing and…

15. July 2013

Definition – Automated Storage and Retrieval System

An "Automated Storage and Retrieval System" (short: AS/RS, sometimes also "Automated small parts…

15. July 2013

Rack zones – bending zone

A rack can be divided into vertical zones based on the scale of an adult (average size of 1.70 m).…

15. July 2013

Rack zones – gripping zone

A rack can be divided into vertical zones based on the scale of an adult (average size of 1.70 m).…

15. July 2013

Rack zones – viewing zone

A rack can be divided into vertical rack based on the scale of an adult (average size of 1.70 m).…

24. June 2013

Application of a storage location management solution

With a growing warehouse, usually not only the number of articles increases, but often a dynamic in…

24. June 2013

External storage

In the case of external storage, storage takes place outside the company. The counterpart is the…