AutoStore is a Norwegian storage technology and, according to the company of the same name, is especially suitable for use as an automated small parts storage. The respective storage system dispenses with classic racks; instead, modular containers are used, which are stacked on top of each other within an aluminium construction and moved by robots. The AutoStore technology basically describes an overall solution, consisting of Goods receiving, Stocking, warehousing, Picking, Packing and Goods dispatch/shipping.

The robot-supported storage and order-picking solution AutoStore is aimed specifically at projects that are usually designed to save space; often such a system is installed in an existing building/project in order to reorganize an existing warehouse section and the associated processes or to automate work steps in the course of digitization – usually these are small project solutions in which, for example, the routes of employees within an order-picking zone are to be optimized: Each manual AutoStore workstation describes the type of picking goods to person.

Advantages and disadvantages of the AutoStore system

advantages>/strong>

- High space and room utilisation

- 24-hour operation possible

- Compact storage

- High automation

- Theft protection (closed system)

- Picking stations are freely installable on the AutoStore system

- The energy saving compared to conventional solutions with storage and retrieval machines is, according to their own statement, over 90 percent

- The expansion of capacity and speed is possible during operation

- Low personnel costs, because only picking stations are operated by people

Disadvantages

- Goods are reduced to the permissible container mass (maximum 35 kilograms)

- High investment costs

- Regular / permanent maintenance by humans

- Applications are limited to simple logistics processes

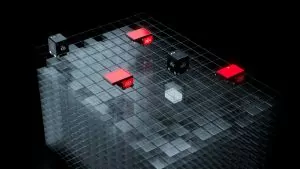

Construction of the AutoStore system

- Container racks made of aluminium, also called grid

- Containers, also known as bins – they are also available in different depths or heights

- Shuttle vehicles, also called robots

- Picking modules, also called ports. They can be placed at any position on the container shelf (grid)

Note from the editors: In order to get to the desired goods quickly, fast movers are kept in stock in the upper section of the stack, slow movers on the other hand in the lower section. In general, thanks to the design, the goods are handled according to the LIFO principle; however, there are also systems that now support FIFO (see link to LIFO); the focus here is on a constant relocation of goods, controlled by the warehouse management system (see the video).

If deeper containers are required, the robots work together to obtain the desired container. In addition, the positions of containers are continuously optimized, so that containers that are frequently requested are stored at a higher level.

Materialflusssysteme / Fördermittel- und Lagertechnik / 4. Edition / Michael ten Hompel, Thorsten Schmidt, Johannes Dregger / Page 72 / Kleinteilelager via AutoStore

Technical component: AutoStore Shuttle (robot)

Technically speaking, robots are conventional shuttle vehicles, but the storage processes, storage and retrieval, are carried out vertically; access to the containers is achieved by lowering a special gripping device. A robot is battery operated and is guided over the grid by a specially programmed routing software (material flow computer or warehouse management). A robot supports four directions (forward, backward, right, left); it lies with its eight wheels, two on each side (see photo), in rails. In practice, the robot picks up the target container, also called bin, and guides it to the desired picking place (port), where the goods including bin are lowered to the picking place. The communication between the systems involved (warehouse management system, material flow computer, host system, shipping system) is usually carried out via the local network, whereas the robots are controlled via a radio link.

Technical element: AutoStore storage construction (grid)

The robots described above move on a so-called rail construction (grid). Each field offers space for several containers, they are firmly integrated into the aluminium construction and appear on the grid as rectangular cells. Although the grid can vary in shape and height, it is limited to a height of 5.4 metres and has a storage capacity of between 2,000 – 200,000 containers per system.

Technical element: AutoStore bin

The transport unit is called bin and can be used project-specifically out of different materials and in different sizes. The special feature is the construction itself; the containers are stacked on top of each other without gaps. According to the manufacturer, it is even possible to adapt the AutoStore installation (the grid) to individual storage situations – building columns and general storage space obstacles are given as examples. Such a container can have a volume of between 48 and 75 liters and can carry a maximum load of up to 35 kilograms.

Technical element: AutoStore picking workstation (port)

AutoStore uses the term Port to describe the classic picking workstation. It can be positioned anywhere on the AutoStore system sides and is supplied with containers and thus with goods by the robots. Once the desired goods have been picked in the specified quantity, the robot picks up the container and puts it back into storage. The storage location can now be redefined by the warehouse management system based on the stock management and the current order volume.

Unmanned warehouses are already possible today, especially in inbound logistics, with full load carriers – when it comes to simple processes. Companies with complex picking processes and a high number of variants, see range of products, cannot do without people as a workforce.

Logistik Heute

Performance of an AutoStore system

The picking performance of an AutoStore system is 180 – 500 items per hour / 120 – 500 totes per workstation. As a rule, with an acceleration of 0.8 m/s2 and a speed of 3.1 m/s, approximately 25 storage and retrieval operations per robot unit are handled per hour. For an average of 2,000 storage or retrieval operations, up to 120 robots must be moved*.

Accordingly, an AutoStore system can also become very expensive and unprofitable. In comparison: A large distribution centre, for example in the fashion sector (shoes, clothing, accessories – without (hanging) bag sorter goods) can handle several thousand items per hour and requires less than 50 people. However, this serious difference in performance is based on the respective orientation of the storage system used. Whereas distribution centers need ample space to grow efficiently, AutoStore is more useful when space is at a premium. Product diversity is also usually a decisive factor in deciding which storage system is awarded the contract. If, for example, there is a wide range of products, a classic warehouse topology with manual picking processes (see two-level picking) is preferred. For smaller assortments, on the other hand, a warehouse system with a high volume utilization and automation level – such as the AutoStore system – will score big.

AutoStore system summary

The AutoStore system is especially suitable for simple logistical warehouse processes. It is usually highly automated and is suitable for small parts (small assortment). It consists of the warehouse structure (grid), the containers (bins) and shuttles (robots) as well as the picking workstations (ports).

*Hörmann Logistics AutoStore Flyer

Image rights>/strong>: AutoStore

Also available in Deutsch (German)

The robots described above move on a so-called rail construction (grid). Each field offers space for several containers, they are firmly integrated into the aluminium construction and appear on the grid as rectangular cells. Although the grid can vary in shape and height, it is limited to a height of 5.4 metres and has a storage capacity of between 2,000 - 200,000 containers per system.

The robots described above move on a so-called rail construction (grid). Each field offers space for several containers, they are firmly integrated into the aluminium construction and appear on the grid as rectangular cells. Although the grid can vary in shape and height, it is limited to a height of 5.4 metres and has a storage capacity of between 2,000 - 200,000 containers per system.

The transport unit is called bin and can be used project-specifically out of different materials and in different sizes. The special feature is the construction itself; the containers are stacked on top of each other without gaps. According to the manufacturer, it is even possible to adapt the AutoStore installation (the grid) to individual storage situations - building columns and general storage space obstacles are given as examples. Such a container can have a volume of between 48 and 75 liters and can carry a maximum load of up to 35 kilograms.

The transport unit is called bin and can be used project-specifically out of different materials and in different sizes. The special feature is the construction itself; the containers are stacked on top of each other without gaps. According to the manufacturer, it is even possible to adapt the AutoStore installation (the grid) to individual storage situations - building columns and general storage space obstacles are given as examples. Such a container can have a volume of between 48 and 75 liters and can carry a maximum load of up to 35 kilograms.