Process chain management serves to organize business processes in intralogistics and other industrial segments. According to Otto Schlichtherle, Logistics IT Consulting, it combines process-oriented thinking with the alignment of processes with the customer order. Prior to the actual optimization, an analysis of the potential and a continuous optimization approach are considered.

Process chain management usually considers individual and already running process sections of the supply chain. These sections are divided into target definitions and examined. The analysis of potential and its individual work steps to be taken into account in this process show how complex a process chain management can be: In general, the requirements analysis is followed by a performance analysis, a process analysis, a structural analysis and a final benchmarking with the help of key figures. After the corresponding analyses and weighing up all possible process optimizations, specialists usually use an individual weak-point analysis – similar to the Kaizen system. The current process is benchmarked against the process assessment, followed by practical and customer-oriented strategies to eliminate the respective weakness.

Process chain management usually considers individual and already running process sections of the supply chain. These sections are divided into target definitions and examined. The analysis of potential and its individual work steps to be taken into account in this process show how complex a process chain management can be: In general, the requirements analysis is followed by a performance analysis, a process analysis, a structural analysis and a final benchmarking with the help of key figures. After the corresponding analyses and weighing up all possible process optimizations, specialists usually use an individual weak-point analysis – similar to the Kaizen system. The current process is benchmarked against the process assessment, followed by practical and customer-oriented strategies to eliminate the respective weakness.

Note: Even if similarities in the approach are unmistakable; the process chain management has nothing to do with the actual state analysis and the target concept, which describe the basics of warehouse planning. The targets defined during warehouse planning only concern the respective warehouse or distribution center currently being planned and are not necessarily customer-oriented. The processes located outside the warehouse are not affected.

Individual sections, detailed target definitions

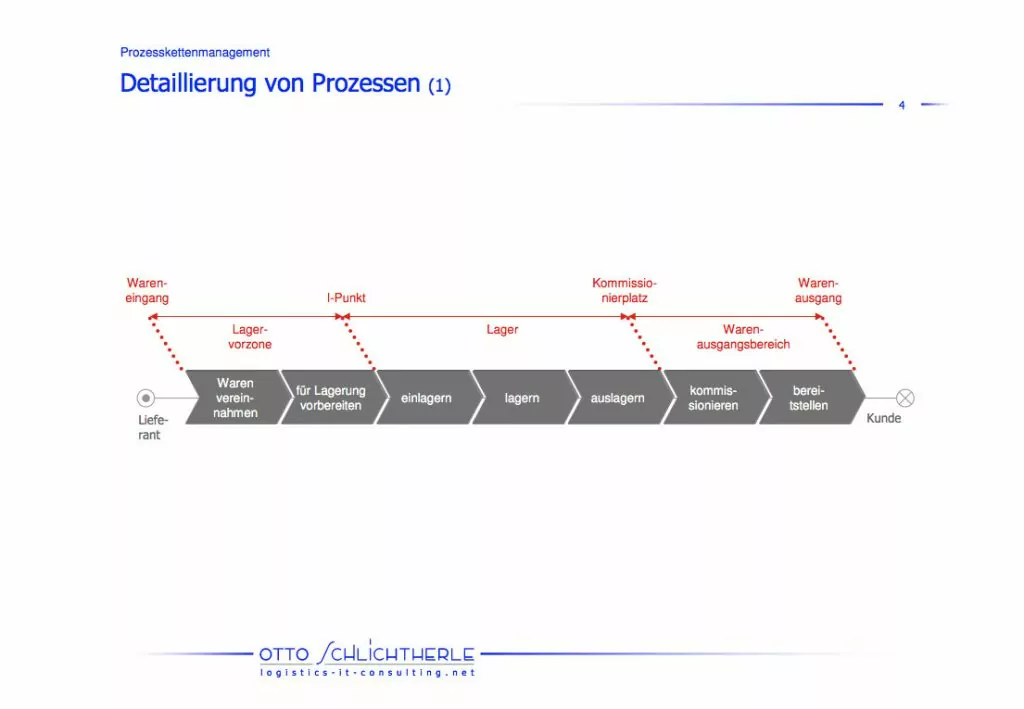

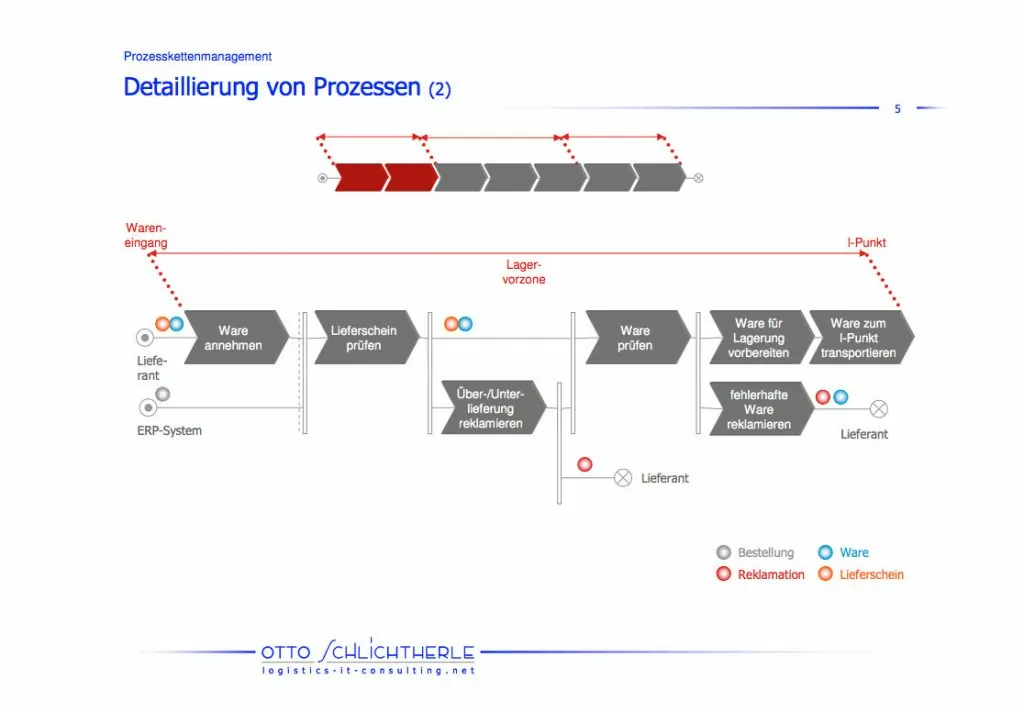

The advantage of dividing individual process sections into target definitions lies in the detail of the resulting representation (see image below). Thus, individual sub-processes must always be depicted in more detail than the entire process including its sub-processes. The disadvantage: Problem cases usually only become apparent in the overall logistics process, since the entire value-added chain is not improved, but only the section under consideration is redesigned.

The advantage of dividing individual process sections into target definitions lies in the detail of the resulting representation (see image below). Thus, individual sub-processes must always be depicted in more detail than the entire process including its sub-processes. The disadvantage: Problem cases usually only become apparent in the overall logistics process, since the entire value-added chain is not improved, but only the section under consideration is redesigned.

All processes are geared to the customer; they must also be designed according to certain criteria in order to effectively manage and control the four target variables of time, costs, quality and service. This also includes the preceding product order of the business customer or end consumer.

Important: If changes are made to the faulty process, a previously functioning process can be affected. The continuous optimization approach is therefore usually not optimally fulfilled. However, in order to ensure a functionally interlocking process chain, the process owner tries to design his optimizations in such a way that at least the process before and the process behind it are not affected. Often these processes function smoothly, but after improvement, they themselves appear to be in need of optimization.

Process chain management: time, costs, quality and service

Especially when it comes to time optimization of the entire ordering process, including the associated and downstream logistics processes (goods must be made ready for dispatch and shipped), process chain management enables a company to react faster and more flexibly to customer wishes or their requirements. This also includes service, which, in addition to the reliable and punctual execution of customer orders within product delivery, also takes into account maintenance and complaints. The quality demanded by the customer has first priority, especially in the sub-areas, service, product and costs.

Application examples for process chain management

Each of the points listed here stands for an individual “partial” process optimization.

- Visualization

- Simulation of business processes

- Modelling of business processes

- Optimization of business processes

- Process cost analysis

- Quality management

- Logistical strategic planning

Summary:

The process chain management is applied in industrial environments (B2B) as well as in the traditional customer segment (B2C). The system optimizations that have been initiated are basically customer-oriented and only solve problems in one area. The entire logistics value chain is not considered because of the inherent complexity. The target parameters to be improved are time, costs, quality and service.

For more information on process chain management, see also Perfect Order Fulfillment and Materials Management in Production.

Teaser image: Dreaming Andy – Fotolia.com

Image in body text: Otto Schlichtherle

Also available in Deutsch (German)