The range of storage is a key figure which expresses the internal security of supply by own stocks of a certain article within a particular article within a certain time. The range of storage indicates how long a stock will last to fulfil existing orders. This, in turn, can be used to determine when the corresponding goods or materials have to be ordered again. The meaningfulness, relevance and consequences are different in manufacturing companies than in trading companies. Still, the common ground remains to avoid both too short and too long a range of storage.

Calculation of the range of storage

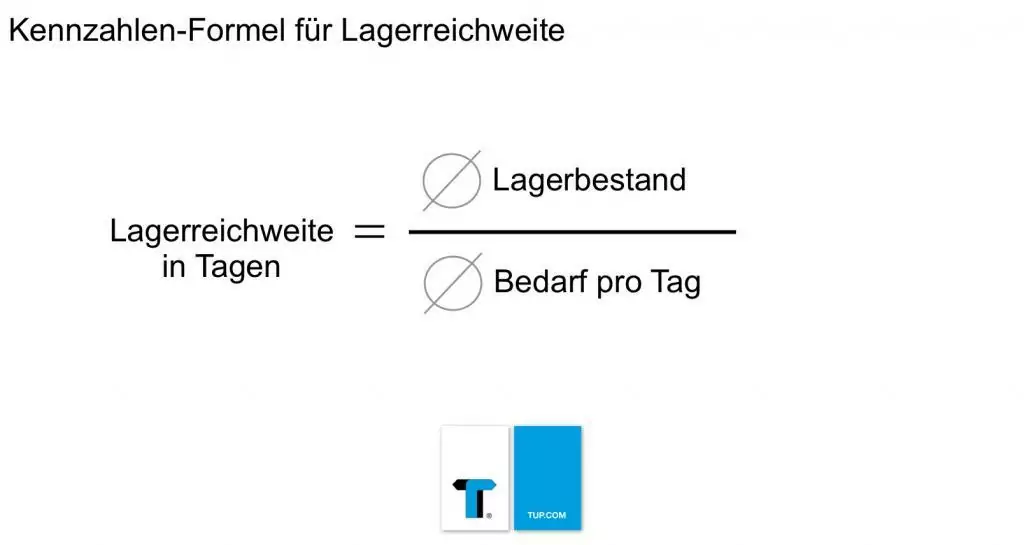

Data from internal systems within a warehouse management system is used for the calculation. To do this, a specific period in the past is considered to determine the average stock and average requirements per time unit.

If three red M-size T-shirts are ordered per day, and 21 of these size-identical copies are in stock, the range of coverage for this article is seven days. This means that delivery bottlenecks for new size M T-shirts can be compensated for seven days and the orders for one week can be expected to be fulfilled.

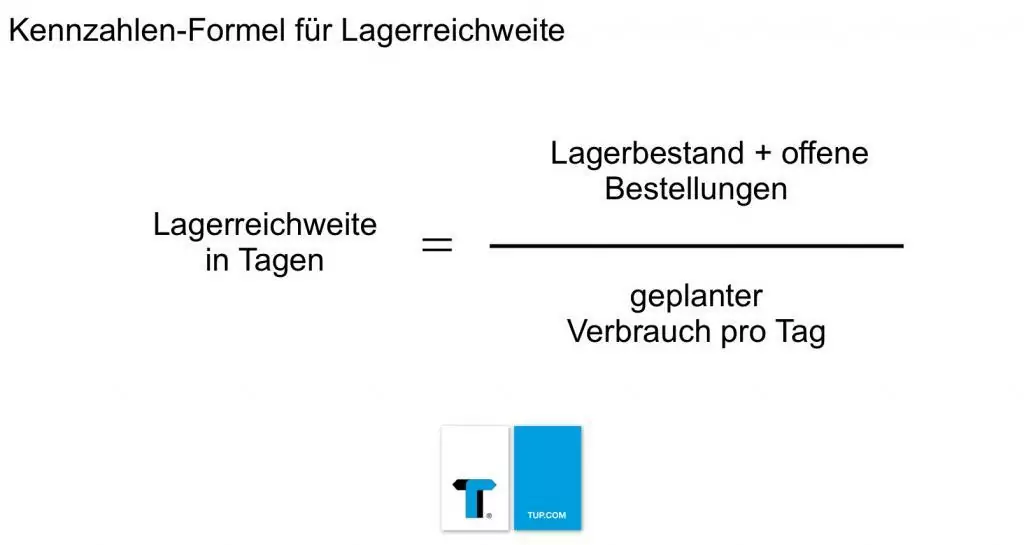

Two alternative calculation formulas include further concrete planning data, but focus on different reference values:

If an average of three red T-shirts are ordered per day, and 21 T-shirts are in stock, this formula also includes an express order for seven T-shirts. This results in a range of storage of 2.8 days. The range of storage is thus more than halved by a single order.

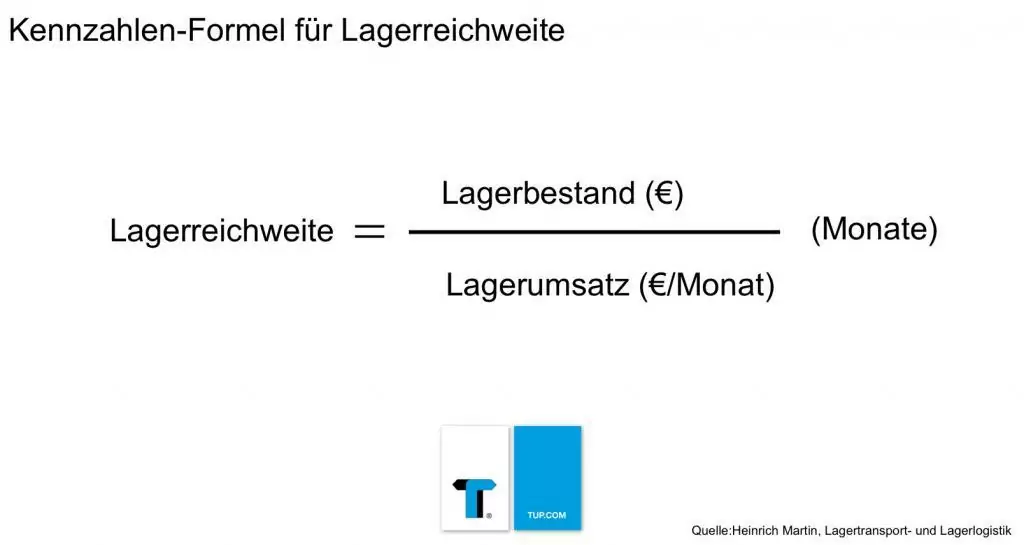

In the third formula, the ‘radius of action’ refers to the reciprocal value of the turnover frequency. Heinrich Martin, Transport and Warehouse Logistics, 8th edition

Editorial note: The formulas can be adapted to other periods so that the range of storage can be mapped not only in days but also in months or years (see formula three). Especially in retail, the selection of periods plays an important role, as many articles are subject to seasonal fluctuations; these can be seasonal (summer/winter) or occasional (Easter/Christmas). But also communication breaks within the supply chain (bullwhip effect) can influence the reach.

In addition to throughput and stock requirements, the decisive factors for warehouse selection and assignment are the resulting wait time and the range of coverage of the stocks to be stored. For example, the exact storage duration of a push stock (current requirement) is already known at the destination point of the putaway. The storage duration of the individual loading units of a pull stock (based on a previous forecast) is not known.

Timm Gudehus, Logistics, 3rd, new edition, page 589

Editorial note: See also push and pull system.

While the industry often strives for just-in-time production and a low range of storage tends to be desirable, the criteria in retail are different. Particularly with sales strategies such as multi-channel or cross-channel, goods are sold on the Internet on several platforms but also stationary in various stores (POS). There, it is always important to ensure that all channels are optimally supplied and that sufficient but not too many goods are in stock. This requires very good informal and logistical networking as well as a corresponding degree of flexibility.

If the range of a warehouse is too small, this leads to bottlenecks and can result in missed (i.e. not made) sales. However, if the range of storage is too high, capital is tied up unnecessarily. For example, goods with a relatively low turnover rate are stored in relatively large quantities, which in turn leads to unnecessarily high storage costs.

Therefore it is vital to determine the optimal range of storage for each article for a specific time and to check it continuously. These key figures then ensure the corresponding planning security in order to place repeat orders with suppliers in line with requirements and reduce the capital commitment mentioned above.

Summary of the range of storage

The range of storage describes the time window (stock) for which the warehouse stock is sufficient for an average or planned consumption of materials or sale of goods. A change in the range of storage is an indicator of changes in the company’s readiness to deliver. A too low range of storage leads to shortage costs, a too high range of storage to unnecessary capital commitment and storage costs.

Images/Graphics: TUP

If you are interested in the subject of warehousing or its range, then you should also read the articles Warehouse Capacity / Warehouse Efficiency and Inventory Management in Intralogistics.

Warehouse management - as simple as possible, as complex as necessary

Our WMS offers you an individually tailored, lean and process-oriented warehouse management.

Also available in Deutsch (German)