Radio Frequency Identification (RFID) is a technology for the unambiguous and contact-free identification of objects (goods, living beings and states) of any kind. It enables fast and automatic data acquisition using electromagnetic waves with the help of transmitter and receiver units. This technology enables new practical applications in the fields of logistics, intralogistics, material management (see Inventory Management), industrial machines, service and identification. If sufficient informationis available in memory, it is called unique identification.

Radio Frequency Identification is increasingly replacing well-known features of barcodes(see advantages and disadvantages of barcodes and RFID) or the optical recognition of objects. Contactless technology is used as a generic term for the entire technical infrastructure and includes the following elements:

- the transponder (also called label, chip or tag)

- the (transmitter) receiver unit (also called reader)

- Integration with servers, services and other systems such as cash register systems (see also POS system), merchandise management systems or forklift or driverless transport systems.

RFID – the history

The first commercial precursors of RFID technology were introduced to the market in the 1960s. These were Electronic Article Surveillance (EAS) systems to prevent theft. At that time, it was only possible to transmit one bit of information. Therefore, only the presence or absence of the marking could be checked. The systems were also based on microwave technology or induction. Many new developments were only introduced in the 1970s to facilitate the use of RFID technology in various areas. The work concentrated primarily on the identification of animals, the use in automation and the automatic identification of vehicles in traffic. The technology was particularly promoted in the 1980s by the decision of several American states and Norway to use RFID transponders in road traffic for toll systems. During the 1990s, tolling technology continued to gain acceptance, and new applications were developed by developing systems for access control, cashless payment, ski passes and fuel cards.

The turn of the millennium brought a sharp drop in the price of technology due to mass production, which also made it possible to use transponders in consumer goods. However, the technology had developed so rapidly that it had ultimately failed to define industry standards. Currently, various institutions and interest groups are increasingly working on extensions, standardisations and standards for technology.

RFID – the technology

There are several transponders, some of which differ greatly from each other. The structure of an RFID transponder consists of an antenna, an analogue circuit for receiving and, if necessary, transmitting, as well as a digital circuit and a permanent memory. RFID transponders can have a rewritable memory on which information can be stored during their service life.

These specifications of the respective chip also differ depending on the area of application:

- Radiofrequency

- Transfer rate

- Lifetime

- Unit cost

- Memory

- Functional scope

Cryptography modules or external sensors such as GPS and temperature gauges can also be integrated into the RFID transponder for special applications (see also environmental measurement). RFID technology is also used inside personnel airlocks. In intralogistics, the tags are primarily used as a guide unit for a forklift control system or driverless transport system. The transponders are embedded in the ground for specific routes. Another standard feature is bulk scanning, in which several tags/articles are identified simultaneously.

Radio Frequency Identification – the systems

RFID systems are related to chip cards. The data is stored on an electronic data carrier as with chip cards. In contrast to chip cards, the energy supply to the data carrier and the data exchange between the data carrier and the reader is carried out by magnetic or electromagnetic fields – not by contact fields.

Radio Frequency Identification usually contains two basic components:

1. A transponder attached to the object to be identified.

2. A reader that can read the transponder and, if necessary, write to it.

The transponder

A transponder is a basic component of an RFID system. It usually consists of the following components:

- Memory

- Coupling element, for example, a coil or an antenna

- Electronic microchip

The following data is stored on the transponder:

- A unique identifier, such as the serial number of the microchip.

- If applicable, information (producer or article number)

Advantages of RFID technology are the possibility of overwriting data and the possibility of supplementing existing information. Sensors, so-called RFID sensor transponders, can also be integrated into RFID transponders. Decisive factors for the size of an RFID transponder are certain requirements on the antenna, the transmission power and the housing. Depending on the frequency or wavelength, the shape and size of the antenna are determined.

The reader

The reader of such a system consists of a reading or writing unit and an antenna. By transmitting electromagnetic waves, an electromagnetic energy field is generated, and the communication between the reader and transponder is realised by radio waves. During communication, the transponder is only active as soon as it enters the reception area of the reader, whereby the actual activation takes place via a coupling unit – similar to the handshake procedure within a modem.

Transponder: passive and active

Passive RFID transponders

They draw their energy for the transmission of information inductively from the received radio waves. The amount of stored data is considerably less than with active RFID transponders. A unique identification number (GUID = Globally Unique Identifier) is usually stored in their memory. Some passive transponders are equipped with a rewritable memory.

Compared to active RFID transponders, passive RFID transponders are smaller and lighter, have a short range, an almost unlimited service life and are comparatively inexpensive.

Features of a passive transponder at a glance:

- Inductive power supply from the received radio waves

- Transponders can only be read

- Low memory capacity

- Memory for unique identification number GUID = Globally Unique Identifier

- Smaller and lighter than active RFID transponders

- Short transmission range

- Virtually unlimited service life

- Cheap

Example of a passive transponder: Smart Label

Passive RFID transponders include, for example, smart labels, which are very thin in form factor and are applied to a film. In this way, they can be used as an adhesive label and affixed directly to products. Communication takes place there via inductive coupling with the reader, usually using a frequency of 13.56 MHz. The transmitter is supplied with energy inductively via the reader.

Smart labels can be classified into three categories: Read-only transponders, Write-Once/Read Many and Read and Write.

Read-only transponders

Read-only transponders can only be fitted with information once, usually by the manufacturer. It is no longer possible to overwrite the data afterwards. Their service life is usually short and process-oriented.

Write-Once/Read Many (WORM)

WORM transponders can only be programmed once by the customer. After saving information, the data can only be read out; the reading out may take place several times.

Read and Write

Read-and-write transponders allow unrestricted labelling and modification of memory content. Many read-and-write transponders also have to write protection, so that the stored information is protected against deletion or overwriting if necessary.

Active RFID transponders

They have their own power supply. Typically, they can be written to and read.

Active RFID transponders usually are in sleep mode, which means that they do not transmit any information. Only when a special activation signal is received does the transmitter activate. Depending on the model, the internal memory can hold up to one million bytes. Compared to passive RFID transponders, active transponders are usually larger, have a longer range, a shorter service life and are significantly more expensive.

Features of an active transponder at a glance:

- Battery operated

- Transponders can be both read and written to

- No transmission of information in idle state – Transmitter activates upon signal

- The memory can hold up to one million bytes, depending on the model

- Relatively large

- High transmission range

- Reduced service life

- Significantly more expensive

Special case: Semi-passive RFID transponders

In contrast to passive transponders, semi-passive transponders have their own power supply, for example, in the form of a battery or a solar cell.

This energy serves only as an energy supply for the RFID chip, not for data transmission. The energy and transmission frequency required for data transmission is obtained by semi-passive transponders, such as passive transponders, via the radio waves of the reader. Since the reader field is no longer needed to power the RFID chip, a weaker field can be used than for operating a passive transponder. This can lead to a significant increase in the communication range if it is possible for the transponder to receive the corresponding signals.

Transponder by polymer printing

Polymer printing or alternative printing processes can now be used to produce flexible and cost-effective RFID transponders (costing less than a cent apiece) – even outside industrial environments. In addition, there are already examples where RFID technology is processed directly into disposable products. The production of RFID tags is, therefore, no longer necessary.

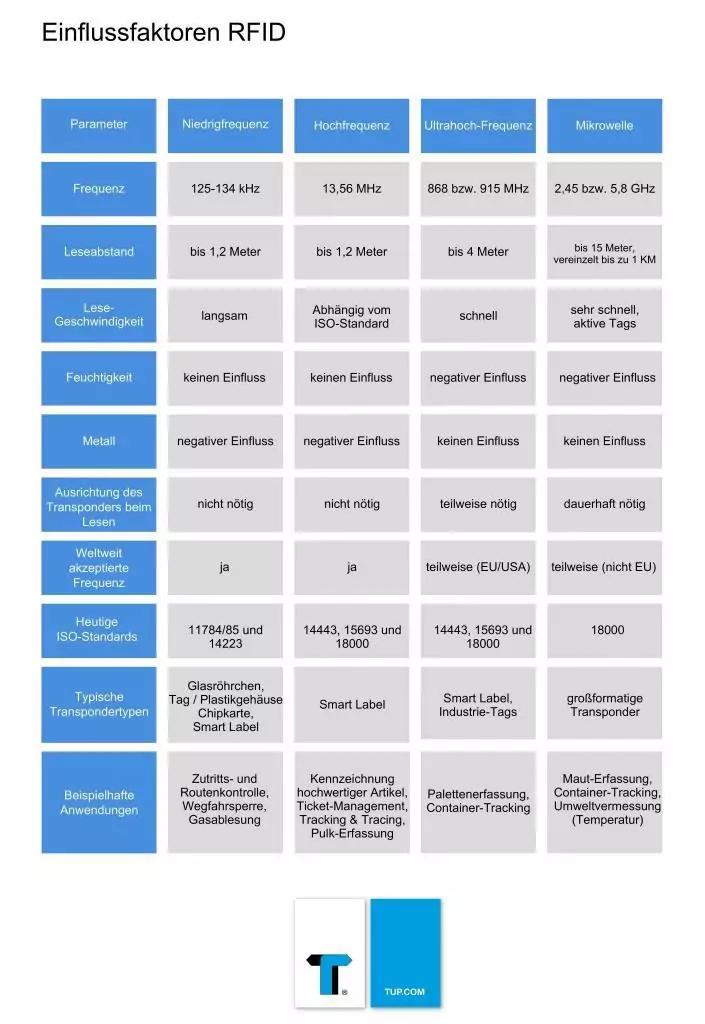

Frequencies and influencing factors

Communication problems

The multitude of different devices and labels is rarely fully compatible with each other. The frequencies used and the preferred standards differ greatly from region to region. Communication problems can also occur with products with high water content (yoghurt, mineral water) and with objects with metal parts (shopping trolleys, car parts, conveyor belts). These can further reduce the already weak emissions of passive RFID transponders. A similar effect can occur if the RFID transponder is attached directly to high-density products.

Summary RFID

RFID (Radio Frequency Identification) describes both the corresponding technology and the technical infrastructure that enables fast, automatic data acquisition via electromagnetic waves. This enables goods, living creatures and conditions to be uniquely identified; contactless. The systems consist of transmitter and receiver units; they differ in their forms, functions and properties. The aim is to establish international standards such as those found in EPAL load carriers.

Teaser image: Maschinenjunge / CC BY-SA 3.0

Also available in Deutsch (German)