Inventory management stands for the complete digital recording of all stock movements in intralogistics in order to obtain reliable information about the storage location (where?), quantity (how much?), and quality (what?) of all products at any time. The statements are collected, combined, and compared with each other from information from the host system and the Warehouse Management System (WMS).

The stock is interpreted differently by the software systems involved – such as the warehouse management system (WMS) and the ERP or host system – but with a common goal: In the totals, both system worlds must always have the same stock!

Stock – Definition

In our definition, we assume two types of stock. One is the stock within a trading company, the other is the stock that is managed in production. The latter includes, for example, the quantities of raw materials and supplies. But also so-called semi-finished products, which are processed further for production, for example, are usually placed in interim storage until they are processed.

The classic stock is kept in the distribution center, both in the central warehouse and in the conventional warehouse. Basically this is the supply of articles/goods. It is therefore also referred to as a physically existing or planned stock of articles, goods, or merchandise. To ensure that production is stopped or replenished, production, logistics, and intralogistics always aim for a minimum stock level, also known as safety stock (see stock types). Important: Inventory is always the property of the respective supplier and must undergo regular inventory – also in order to be individually evaluated for new events.

Commercial and logistical stock

As a rule, the WMS has stock control, because only the warehouse management system knows the exact stock level for each storage location and each pallet. Other project-specific logistical ‘stock qualifiers’ (attributes) can also decide on the logistical availability of each individual item of goods (or pallet, carton/packaging material, storage compartment).

The ERP system, on the other hand, only knows the total stock and the attributes relevant for a commercial system. Logistical inventory qualifiers such as goods in movement or individual storage bin coordinates are usually not known to the ERP system. The commercial view therefore focuses on the following events:

- New available stock is created at goods receipt.

- When customer orders are dispatched, available stock becomes reserved stock.

- On dispatch, the reserved stock is again reduced by the dispatch quantity.

This is a very simplified description. It is usually complicated by numerous special cases. Examples of these:

- Corrections to available stock by finer ‘stock qualifiers’ such as blocks due to non-tested or insufficient quality, customs status, country of origin.

- Stock corrections due to missing quantities or new stock findings.

- Shift between reserved and available stock due to order changes such as canceled orders.

The ERP system often only receives information about stock changes (see Stock reconciliation) cyclically and thus updates its data compared to the warehouse management system. The reasons for this are:

- Goods that are currently being moved

- Blocked goods

- Pre-orders

- Changes in inventory are not posted online

- Returns/ damaged and not yet booked goods

Stock comparison

A regular stock comparison, for example between online trade (online shop) and the stock levels of inventory management, is extremely important nowadays. As a rule, each system manages its own stock – online shop and merchandise management (distribution, brand, middlemen) use different databases. Only appropriate interfaces enable a delayed synchronization of the inventory of both systems.

Die Schwierigkeit liegt heutzutage in der Vielfalt der unterschiedlichen Verkaufskanäle – sie alle können sich aus demselben Lagerbestand bedienen; durch die unterschiedlichen Systemebenen überschreibt aber das übergeordnete System (Warenwirtschaft) die Bestände der untergeordneten Systeme.

The stock reconciliation is a cyclical report of all stocks in the system. It is used to correct errors, for example in the transmission of stock reports, manual postings, or order confirmations.

Stefan Fehrenbach, Dr. Thomas + Partner

In the meantime, the stationary trade (point of sale) has reacted and optimized its so-called branch logistics to merchandise management. Using mobile devices, local retailers can access the entire range of merchandise management products – the central warehouse displays the entire inventory in ‘real-time’ and automatically carries out the above-mentioned inventory report and correction to the above-mentioned stock-keeping unit (SKU), for example when a sale is concluded – but this is not an inventory comparison. Nevertheless, the advantage is obvious: reduction of -rates (stock gaps). This type of gaps can occur when the following situations arise:

- Articles in local shops are no longer put back in the space provided for them (misplacement)

- The goods arrive too late in goods receipt (missing advice notes) and therefore cannot be delivered to the retailer on time

- Inventory gaps due to shrinkage: This describes, among other things, theft, expired shelf life, article damage (also packaging), and errors during picking (miscounts).

Important information during an inventory comparison

For an ERP system, information such as quantity, item number, and quality (A goods, B goods, C goods) is important – not so much the minimum durability. Nevertheless, specific project requirements may require additional attributes, such as location (where the inventory reports come from: central warehouse, branch, online shop).

In addition to the storage and retrieval of goods, from the perspective of the warehouse management system, the inventory management system also manages stocks already recorded during a stock transfer. The current location is unknown, and the goods are therefore temporarily not accessible. Good examples of ‘movement fuzziness’ when determining the current stock are, for example, transfers between reserve and picking warehouses or transfers between decentralized warehouse locations.

Important: A prompt data exchange between warehouse management and the host is an absolute prerequisite for up-to-date inventory information in the ERP and error-free synchronization between both systems.

Stock types in the overview (selection)

- Physical stock– Physical stock is generally the stock of goods available in a site at a particular time, for example, during a physical inventory. As long as each stock movement is tracked in the system promptly and correctly in terms of quantity, the physical stock should always correspond to the book inventory balance (see below).

- Book inventory – Describes the target inventory available according to the accounting records. The book inventory balance can deviate from the actual stock – see Physical Stock – due to incorrect or delayed postings, errors in quantity entry, or damage to the goods, etc.

- Inventory stock – The book inventory at year-end closing (= inventory stock) is reported by the WMS to the business system. In the inventory procedures, we differentiate, for example, between continuous inventory and an annual inventory on a key date. The challenge for the distribution center: During the key-date inventory, no goods may be moved in the warehouse on the one hand, and no open postings or orders may exist on the other.

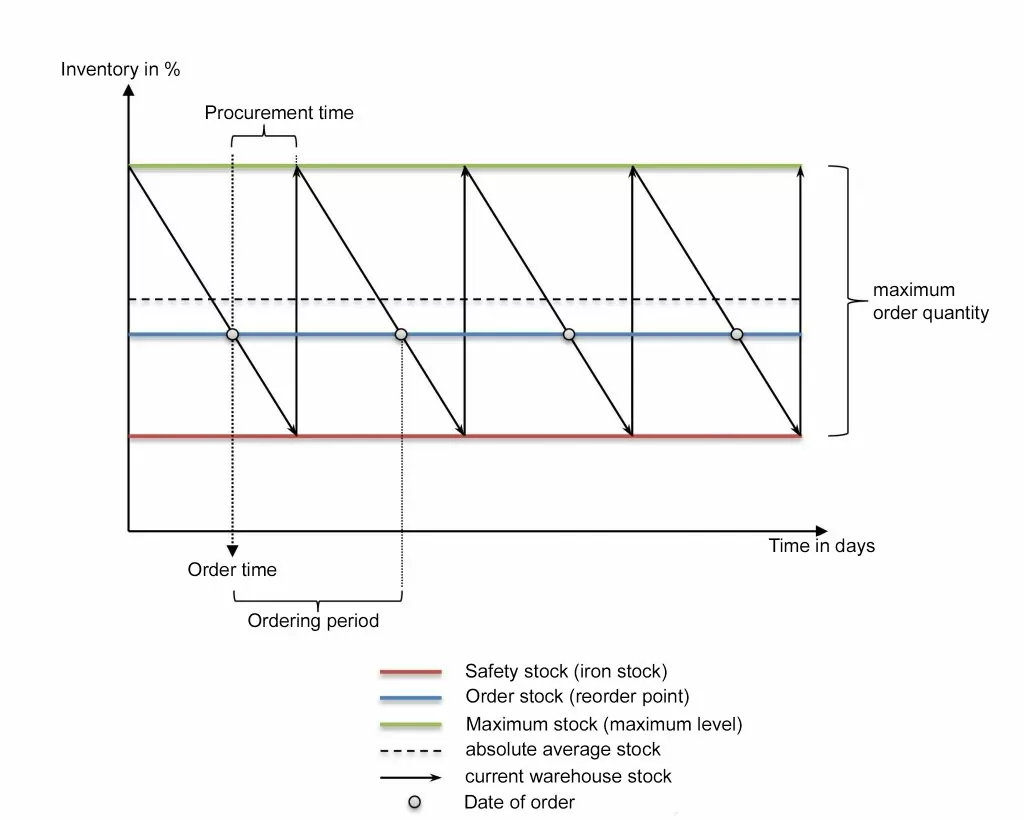

- Safety stock– This is the lower limit of the available stock for procurement/purchasing and should not be fallen below in the warehouse; so that a smooth process is guaranteed even in the event of unforeseeable incidents. It covers the uncertainties of delivery time, demand, and stock. It depends on the actual consumption (day, month, quarter). In addition, those responsible must take into account the replenishment time, including the delivery time.

- Maximum stock – The counterpart of safety stock: The available quantity of a product should not exceed a defined maximum number of units. The avoidance of high stock levels prevents a high capital commitment (this stands for non-liquid, unavailable assets: stocks, machines, space).

Note: In practice, these two absolute quantities (safety stock and maximum stock) are replaced by ‘ranges of coverage’ (stock level through sales per time = range of coverage in days, weeks, months).

- Available stock – This is determined by reducing the book inventory by the open purchase orders/sales orders. Quantities that cannot be planned for other reasons (for example, goods waiting for quality releases) are also deducted.

Important: Deviations between physical stock and book inventory must be detected by suitable control mechanisms in the warehouse and then reported to the higher-level ERP as a ‘stock correction’.

Identification of existing stocks

To ensure that the identification of all stocks functions smoothly, the necessary information(e.g. unique identification number, batch number on the identifiers, or barcodes attached to the respective product) is stored. However, the ‘how’ is decided very individually and project-specific on site. The minimum form is coding with an identification number that is unique in the system; an IT system usually does not require more than this. However, the employee is given the opportunity to make decisions without the IT system or to check plausibility independently of the IT system. The labels on a storage unit are therefore usually supplemented with plain text information such as article, batch, and other information. Changing characteristics of a storage unit, such as storage location, quantity, are not likely to be printed. Distribution centers use various techniques for the physical coding of storage units. For example, an ‘over-corner label’ can be used for readings on the conveyor system that is independent of direction.

Important: For the ERP, even the quantities already picked in customer packages are usually still counted as stock, as long as they have not actually left the warehouse. In addition to the inventory management of the respective customer products, a WMS often also has to manage the movements of empties such as reusable pallets, skeleton containers, and the like.

Returns, food and medicines

Returns are also returned to the system as stock receipts via the inventory management (returns processing). In this case, however, the commercial credit note is issued before the goods are put away again – the WMS only becomes aware of the receipt of a return when:

- the goods have been unpacked, assessed and a decision made on a credit note – usually outside the warehouse management

- the goods have been reconditioned for dispatch after a positive quality check

- Put it the other way round: If an incoming return is not put back into storage after evaluation – i.e. destroyed – it is of no interest for a warehouse management

In the case of food and medicines, further tasks arise for warehouse management in connection with ‘batch management’. The legal regulations to be observed must be taken into account during storage and retrieval, but also during transfer and sorting. As a rule, transport as well as storage and sale are recorded up to the end consumer and can be traced via the respective batch number.

In logistics, environmental conditions continue to play a role to the extent that rules for the selection of storage areas or shipping with certain carriers or services can be derived from corresponding specifications in the article master (‘chilled goods’).

Stock management for goods subject to customs clearance

When importing uncleared goods from a non-EU country

- the goods must either be stored in a separate bonded warehouse until customs clearance (classic solution)

- the conditions under which an uncleared carton may be stored in the warehouse among the cleared goods must be negotiated with customs. However, if the goods are not cleared through customs until they are removed from the warehouse, the customs requirements are non-trivial.

- in practice, the goods are often already cleared through customs on delivery. The reason: Both of the above-mentioned variants involve high costs in practical application.

In a nutshell:

Inventory management is the central part of a WMS that keeps records of all movements of goods. It also plays an important role in the inventory and keeps the information available, such as blocked, available, or unavailable goods. To ensure that available and unavailable goods are known to both the WMS and the ERP system, the WMS regularly compares this data with the ERP system. The described differences in the view of the stock data between ERP and WMS systems make it difficult to synchronize the stock on both sides.

For more information on inventory management, see also the article “Order processing: Load order data” and Customs warehouse.

Also available in Deutsch (German)