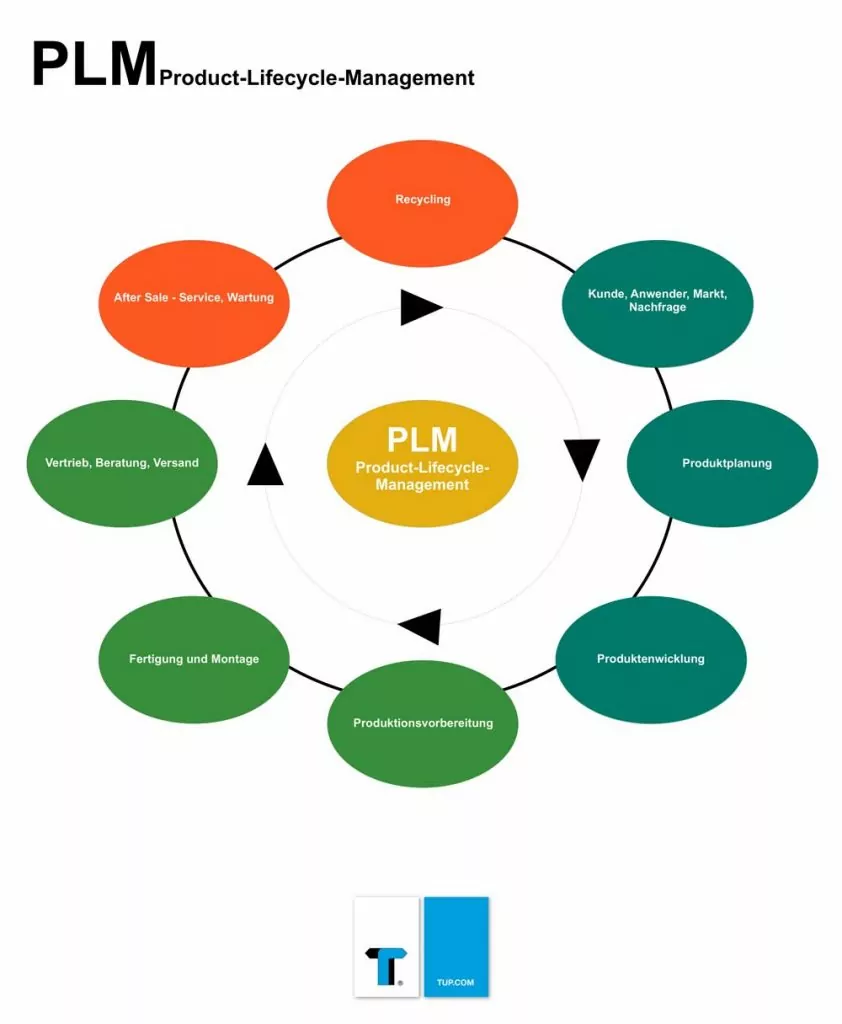

The term Product Lifecycle Management, PLM for short, describes a holistic approach to pooling product information. It is a kind of cross-company management and control of the information flow of a product along the entire value chain. The industry refers to the gathering of information that is generated during the course of a product life cycle. This includes informationfrom design, production, sales, services, dismantling and recycling.

Product lifecycle management is basically based on detailed product information, which is initially generated in the course of product planning and production. This includes product data that is collected outside the company, at external service providers and suppliers along the supply chain and stored in a structured manner. As a rule, the management structure of PLM can be divided into three phases:

- Beginning of Life (BoL)

- Middle of Life (MoL)

- End of Life (EoL)

One of the goals of PLM is to provide employees with product information on request in high quality, including additional information (images, videos) in the right place (see PLM Benefits). The three phases mentioned above include the following information interfaces:

- Raw material extraction, suppliers

- Development (design processes), construction, production of new products; including machine and software information, during production.

- Sales, cooperation with suppliers, warranty management, customer communication

- Disposal, take products off the market (product discontinuation), recycling

Important: PLM not only uses information about the respective product. Persons and their know-how are also taken into account or included who are suitable for the solution of concrete product questions. This includes process improvements and completed success stories that generally improve company productivity. A kind of social network within the company.

Product Lifecycle Management is the product-related and cross-company information management. PLM encompasses the planning, control and organization of the processes required to create and holistically manage all data, documents and resources throughout the entire product life cycle.

Technical University of Kaiserslautern, Chair for Virtual Product Development

Vorteile Product Lifecycle Management – PLM

- Planning and production become transparent.

- New standards are created.

- Product is transparent throughout.

- Strengthening competitiveness.

- Involved employees are all on the same level of knowledge.

- Productivity through repeatable and successful processes.

Important: PLM is usually a software-based information system characterized by a so-called coherent data structure. In other words, the information is not only coherent; the systems involved act in a consolidating manner. In addition to the classic product information, suitable interfaces provide on the one hand the corresponding information of the producing and transporting peripherals, on the other hand, it is possible to monitor product developments across companies.

For the implementation of a product lifecycle management, companies often rely on a so-called ‘Product Data Management’ (PDM). It is a software that specifies how product data (documents) and product information are stored and managed.

Further information on this topic can also be found under Supply Chain Management and ‘What is Supply Chain Management about?‘.

Teaser image: Max Pixel

Also available in Deutsch (German)