The one-dimensional bar code is commonly used to label goods and services. However, since the data density of such codes is low, applications intended for this purpose use two-dimensional codes (2D codes or 2D barcodes) whose data capacity exceeds that of conventional barcodes or barcodes many times over.

Two-dimensional codes are therefore used when a larger information memory is required than with one-dimensional codes. There are two main groups of two-dimensional codes: Stack codes represent stacked, one-dimensional barcodes, while matrix codes consist of square or rectangular patterns.

Stacked codes

In contrast to one-dimensional bar codes, stacked codes consist of a two-dimensional bit pattern, which, as mentioned above, has a square structure. Stacked codes use the Y-axis in addition to the X-axis in their area, and by stacking several one-dimensional bar code lines within this area, the amount of data can be significantly increased. The number of characters that can be stored is calculated by multiplying the one-line capacity by the number of lines. Slightly modified laser scanners can be used to read these stacked codes. The image of the 2D barcode is read in a simple mode of operation and decoded by an image processing program. In addition to industrial handhelds and so-called MDE devices (see also Pick-by-Scan), smartphones can also read such codes. Stacked codes are, for example, PDF417, Codablock, Code 49, Code 16K.

Advantage and disadvantage of stacked codes

- The advantage of stacked codes is that the area for this code can be kept relatively small due to stacking. This means that more information can be accommodated per area compared to one-dimensional bar codes. If the code is therefore printed in high resolution, the section of the code can also be much smaller; keyword: space-saving.

- The disadvantage is that there is an additional effort in reading technology (see also CCD camera) compared to standard bar codes. In practice, scanning times, for example, can have a negative effect on subsequent work processes, for example, within order picking. If the code structures of standard bar codes are retained, and the reading device works according to industrial standards (correct scanner instead of camera), this additional work is minimal.

Matrix codes

Matrix codes were developed parallel to the stacked codes. With this type of code, a complex reading technique is used. Matrix code is composed of various geometric shapes, mostly dots, rectangles and hexagons. Examples of a matrix code are DataMatrix, MaxiCode, AztecCode, QR-Code.

Advantages and disadvantages of matrix codes

- The advantage of matrix codes is that the area for the code can be kept relatively small and thus, compared to one-dimensional codes, more information can be accommodated per area. The code is also readable at any angle of rotation. Compared to stacked codes, the code size is smaller while the information content is higher.

- The disadvantage is that camera-supported image processing systems are necessary to decode the matrix code. Furthermore, two-dimensional codes generally place higher demands on printing technology. A major stumbling block in advance of codes is still the lack of standardisation. However, this is to be achieved step by step, both country-specifically and transnationally; for example, the matrix code type ‘QR code’ has become a national standard in several countries.

QR code

A QR code belongs to the group of matrix codes. QR means ‘quick response’. This two-dimensional code can be used to guide users to texts and other multimedia content that is, for example, in a format optimised for smartphones. Usually, a command stored in the QR code opens a specific app – for example, the web browser.

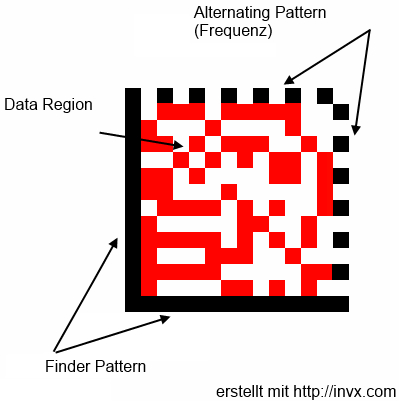

It is composed of light and dark modules that together form a square matrix. Exactly eight modules form a code word. These modules do not necessarily have to be black or white; the decisive factor is that there is a high contrast between the light and dark modules. By means of the so-called ‘Finder patterns’, which are located in three of the four corners, it is possible to recognise the code as such. They are always placed at the same positions in the QR Code and thus determine the orientation of the code. A ‘Finder pattern’ is always seven modules wide. Between these three marks, there is a line, the so-called ‘Timing pattern’.

A built-in error correction means that a QR code can still be read even if it is not 100 per cent readable or even somewhat soiled. This means that the code can still be decoded up to a loss of 30 per cent. The higher the level of error correction, the fewer data the QR code can hold. While, as mentioned above, it has already been registered as a national standard in several countries, the QR code has also undergone several technical advancements:

- Design QR code (also custom QR code, individualised by graphic design such as logo, lettering or image; adaptation to corporate designs and for use in marketing campaigns; exploits the error tolerance of the QR code)

- Micro QR code (QR code variant optimised for minimum dimensions)

- Secure QR code (SQRC, contains a function for encrypting data contents)

- iQR code (can also have the shape of a rectangle and be placed on a cylindrical object, for example; similar to micro QR code, it offers high data density in a very small space)

- Frame QR code (for the use of graphic elements as well as the design QR code; however, the error tolerance is not used or impaired, but free space is created around which the actual QR code is placed; the free drawing area can then be graphically designed; the frame QR code is not compatible with conventional QR codes and requires another app for reading out)

DataMatrix code

The DataMatrix code, together with the QR code, is one of the best-known 2D codes and has established itself mainly in industrial production, where it is applied as permanent marking by laser or needle engraving to identify individual components. In the meantime, however, it is also used in document handling as a printed code image, as for example by the German Post Office or the pharmaceutical industry in the example below.

The following video gives an impression of how small DataMatrix codes can be.

Like the QR code, the DataMatrix code also has error correction; it can be square or rectangular and can also be placed on cylindrical surfaces and read out. The DataMatrix code is defined in the international standard ISO/IEC 16022 and is used in its variant with error correction ECC200 (Reed-Solomon algorithm) together with the GS1data structure. This has led to the term ‘GS1 DataMatrix’, which does not describe a separate code, but only the configuration of these components. On the one hand, its technical properties and on the other hand its international standardisation are driving the spread of the DataMatrix code more and more.

Applications

Editor’s note: The use of multidimensional codes, in particular QR codes, must be seen in a broader context: Mobile data collection, which also includes RFID systems.

In many areas of logistics, it is necessary to compare the location, logistics status and identification of a good or a means of production. This is where mobile data acquisition is particularly helpful.

seton.de

Originally, QR codes were used in production logistics, but have now found their way into everyday social life. The classic barcode is still used intensively in logistics and material flow, but it is often only needed for identification purposes, while the actual information is stored in other systems (ERP system, warehouse management, inventory management system). However, it is matrix codes such as QR code and DataMatrix code that offer a very large innovation potential. For example, stationary printers are now able to apply codes to the packaging at high speed in order to uniquely identify the goods. The batch numbers used up to now are being replaced by serialised marking on each individual package; this is successfully practised in the pharmaceutical industry, for example, with medicine packages. The much greater information content of such codes simplifies documentation on the one hand and makes business processes audit-proof on the other. In addition, it is now standard practice to combine different code variants.

Case study: SecurPharm

On February 9, the new security system for drugs ‘securPharm’ went online. The same-named german organisation securPharm e.V., which was initiated by industry, wholesalers and pharmacists, has developed this system in accordance with the requirements of the EU Counterfeit Protection Directive 2011/62/EU. From now on, the packages of prescriptive drugs newly marketed by manufacturers will be equipped with two additional security features that are checked directly before being given to the patient.

This EU directive states that each package has a so-called unique identifier consisting of the product code, serial number, batch and expiry date printed as a 2D barcode. In addition, each package must be sealed in order to determine whether it has ever been opened. These packages must be verified end-to-end using data technology. This means that when a package is produced, the manufacturer uploads the data of the unique identifier into an EU-wide database. When the carton pack is delivered to the end consumer, the carton pack must be booked out of the database. Between the producer and the end-user, the package can be verified as often as required. This involves a query of the unique identifier in the database, which, on the one hand, checks whether it exists and, on the other hand, whether it has not yet been booked out. A classic barcode would become much too large for this amount of information, which is why the data mentioned above is encoded in a DataMatrix code (ISO/IEC 16022).

Summary two-dimensional codes / 2D codes

Multidimensional codes (also two-dimensional codes or 2D codes) have a much larger information memory than one-dimensional codes; they are divided into stacked codes and matrix codes. The QR code is one of the most widespread and well-known matrix codes, since it can be both created and read without special technical knowledge or complex tools, and offers a balanced ratio of space and data capacity. Compared to the classic barcode, the QR code still has generous error tolerance, which means that it can be read even if it is damaged. QR codes are used just as efficiently in warehouse management, for example, as in everyday life or advertising. But the DataMatrix code has also become established by users such as Deutsche Post, where it is used for IT franking.

Also available in Deutsch (German)