Dead time is an unproductive but unavoidable so-called auxiliary time, which arises during picking due to preparatory and follow-up activities (e.g. search and identification of the storage location). It can be optimized by simple measures.

The following applies: The activities that occur for each order item at the picking location and cannot be directly assigned to the actual picking process belong to the dead time. On average, it takes up 10-25 percent of the total picking time (1). For comparison:

- Picking time: 25-35 percent

- Travel time: 40-60 percent

- Base time: 05-10 percent

Calculation of picking time and dead time processes

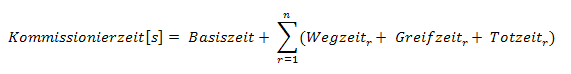

If you look at the base time, all the picking time segments listed above depend on the number of items in a single picking order. For the Technical University of Munich, the following formula is used to calculate the total picking time. n describes the number of individual orders.

In addition to the search and identification of the stored goods, the following process steps belong to the dead time

- Control of the commissioned articles

- read operations

- Reaction to picking errors

- Acknowledgement

Optimization of dead time

As described above, reading and checking articles and entering information can cost the order picker valuable time. This unproductive time can be longer than productive picking time due to inadequate storage location identification, inappropriate input technology, real-time inventory reconciliation and excessive information. It is therefore common for Warehouse Management Systems (WMS) to generate system-related waiting times of up to five seconds for uncoordinated warehouse processes. In the age of e-commerce, self-sufficient picking systems or controls should, therefore, be used in modern distribution centers (2). This means that order picking is initially decoupled from the actual stock management. When an order is placed from the webshop, the article is immediately reserved for the customer via the ERP system. The order picker starts his tour, removes the order-relevant articles without forcing online synchronization with the system above. Only at the end of the tour is the removal synchronized online. Advantage: The order picker can process his tour smoothly without having to wait for feedback from other systems (e.g. ERP). The waiting times caused by the system, as described above, are thus bridged.

The dead time can also be easily optimized using the following methods

- Clear identification of the racks (see Storage location management)

- Pre-packaging or pre-picking in different quantities

- Electronic counting processes (e.g. via RFID)

- Digital navigation via data glasses and Smartwatch

- No so-called packaging breaks are given. Only pre-packaged quantities are dispatched to the customer.

Important: Dead time is not to be equated with distribution time, which also does not record any productive work, but is usually caused by personal influences.

Various factors influence dead time. These include the presentation and preparation of information, the quality of employees and the ergonomics of the workplace.

Summary Dead time

The dead time is made up of work steps that inevitably occur during the processing of a picking order or batch, but are not part of the actual productive processing. This includes, among other things:

- Searching for the storage location

- Opening packages (see “Optimizing Dead Time”)

- Counting, weighing, measuring articles

- Checking the article to be picked

- Note removal (acknowledgement)

(1) Jens Wisser, The Storage and Picking Process within the Distribution Center Reference Model.

(2) Tim Gudehus, Logistics – Fundamentals, Strategies, Applications, 4th updated edition, page 693. 17.4, Picking quality

For more information on order picking go see the following articles: Man-to-goods picking, Goods-to-man picking.

Teaser picture: KBS Industrieelektronik GmbH / License: CC BY-SA 3.0

Also available in Deutsch (German)