There are various handling methods for inventory in the shipping area. One of these handling methods is called cross docking. The special feature of this type of transshipment is that storage is not required. Instead, the inventory is already pre-picked by the supplier or sender. Delivered items are now not placed in storage, but assigned directly to the corresponding goods issues and dispatched further.

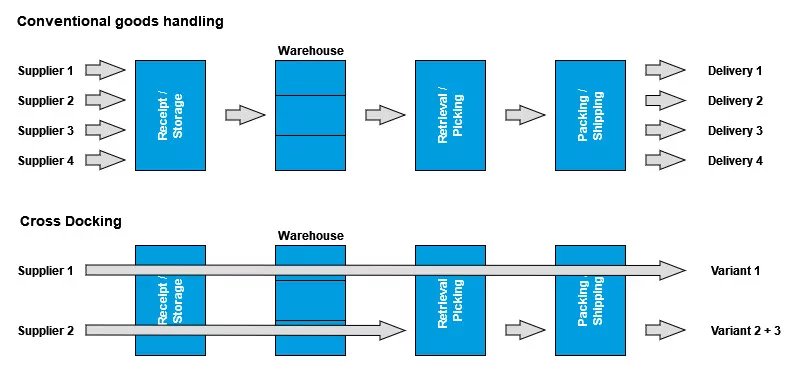

A classic supply chain needs a warehouse that acts as a link between seller and buyer or between supplier and consumer. However, this link also represents a disruption in the path that a product takes. Supply and demand are not synchronized, which is why it is necessary to store inventory until the moment when it is needed or ordered. Storage interrupts the flow, which is mitigated or prevented by cross-docking, as there are no putaway processes and associated activities in cross-docking. As a result, inventory costs and the number of process steps (and thus potential sources of error) are reduced.

Benefits of cross docking include creating lower throughput times, timely delivery, reducing inventory, minimizing storage space requirements, eliminating storage and retrieval processes, and reducing inventory costs.

Overview of the three cross-docking variants

There are three variants, or systems, in cross docking:

- single-stage

- two-stage

- multi-stage

The single-stage variant requires pre-picking by the supplier related to the final recipient. Via one or more handling points, the inventories are passed on unchanged to the recipient. For successful implementation, it is necessary for the sender to mark the goods with the name of the addressee beforehand, which is usually done directly on or at the inventory. Another name for single-stage cross-docking is also Pre-Allocated Cross-Docking (PAXD).

In the two-stage system, the inventory is forwarded unchanged only as far as the transshipment point. From there, it is transhipped into new units and addressed and consequently delivered to the appropriate consignees. Two-stage cross-docking is also called break-bulk cross-docking (BBXD) or even more commonly: Transshipment.

Multi-stage ‘cross docking’in addition to the actual re-picking, includes other process steps, which are so-called ‘value-added services’. Examples of this are the possible repackaging of items or the labeling of inventory.

Advantages of cross docking versus conventional warehousing

More capital is tied up in warehousing and more resources such as time and labor are also required than in the cross-docking process. However, for cross docking to work efficiently, carriers, warehouses, suppliers and also end-consumers must be optimally coordinated and work together accordingly. To achieve this, the manual processes must not only function smoothly but also the information flows between the parties involved. As a result, the process steps of classic warehousing are no longer required: receiving and storage, warehousing, as well as retrieval and picking.

A condition and at the same time an advantage of cross-docking is therefore the timely delivery: Since inventory only takes the way from goods receipt to goods issue in order to be transported on promptly, it must not “come sometime” and “stand around somewhere” at all, but must be processed further without delay, which only works in a joint approach in cross-docking. Therefore, all parties involved in the supply chain must be permanently integrated in the process and in the flow of information during cross docking.

This requires IT solutions that meet very high standards, as the exchange of data and information must take place in real-time, so to speak. Criteria for this are, for example:

- Correct master data

- Up-to-date transaction data

- Synchronization of inventory and information flows

- Integration of third-party systems, software as well as hardware

- Transparency of data

An example of the cross-docking process

The assortment of a company with several stores consists of, among other things, pants and belts. The pants are manufactured in-house, while the belts are purchased. Classic warehouse logistics would now look like this: both the pants and the belts are stored together. When the stores then order these inventories, both the pants and the belts are picked, packed and prepared for shipment. With cross-docking, on the other hand, only the pants from the company’s own production would be stored, while the belts would be delivered to the cross-docking point in due time by the supplier and immediately processed in the shipping area (for example, re-picked, re-packed, labeled) so that they can be shipped to the stores without delay, together with the pants from the warehouse that have already been transported to the cross-docking point. Cross docking is thus also an adequate means to avoid partial truckloads in deliveries and to utilize the loading area as much as possible; therefore achieving FTL transports (Full Truck Load) and avoiding LTL transports (Less than Truck Load).

Summary

Cross docking is a type of transshipment in which delivered inventory is not put into storage but is assigned to the corresponding outgoing goods and shipped on. The alternative spellings cross-docking is also common. The inventory is pre-picked by the sender or supplier, which ultimately reduces inventory costs and throughput times. In cross-docking, there are single-stage, two-stage and multi-stage variants, which differ in the corresponding activities – from simple pre-picking to re-picking and further process steps such as re-packaging or labeling. The storage points in the supply chain used for cross-docking are also called cross-docking points. These are usually a retailer’s central distribution center or a logistics service provider’s terminal. Thus, cross-docking is particularly suitable when large and plannable quantities are involved, where all participants in the supply chain work together in a coordinated manner and an optimal flow of information is ensured.

For more information on goods handling, see the article Transshipment logistics.

Also available in Deutsch (German)