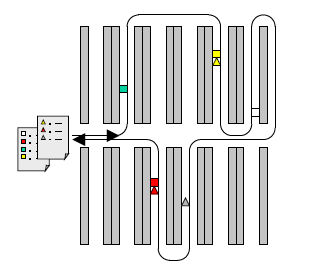

During picking, a certain quantity of articles is picked from an assortment and put together. Picking in a warehouse can be single-stage or multi-stage. In single-stage picking, the picker always works on an order-related basis as he moves through the warehouse, which means that the goods do not have to be sorted afterwards. In two-stage picking, a downstream sorting instance allows the picker to be largely detached from the order reference.

Single-stage picking

One form of single-stage picking is picking without system support. The basis for this is that the existing assortment is stored in the warehouse in a clear and structured manner. By storing the articles by ascending article number, the picker should not have to spend a lot of time searching for the goods. This enables fast access. By means of article information on the delivery note or the invoice, the picker identifies the desired goods in the warehouse.

Extension to several orders

If the article assortment in the warehouse is so large that the routes for picking are considered unacceptable, two options can be taken.

- Detaching excess stock into a reserve area

- Combining several orders into a joint picking tour

During a tour of the warehouse, in which several orders are picked together, the picker carries several delivery notes with him. By regularly removing articles from the assortment, expanding the assortment with new articles or even replacing goods with substitute goods, it is difficult to maintain the warehouse structure according to an ascending article sequence. For this purpose, storage location management can make the picker’s work easier.

For more information on single-level picking, see Single-stage picking – order-oriented, serial picking.

Image source: © Endostock – Fotolia.com

Also available in Deutsch (German)