In the putaway business process, articles are picked up, transported and stored in the warehouse. The articles can be identified and assigned to a storage location using labels that were previously attached in the business process Goods Receipt. After successful incoming goods inspection, the goods are passed on from goods receipt to putaway, a process consisting of individual process steps. Accordingly, typical tasks that take place during putaway include:

- Acceptance of the transfer order

- Identification of the article

- Inclusion of the article

- Transport of the article to the warehouse

- Storing the article in the corresponding storage compartment

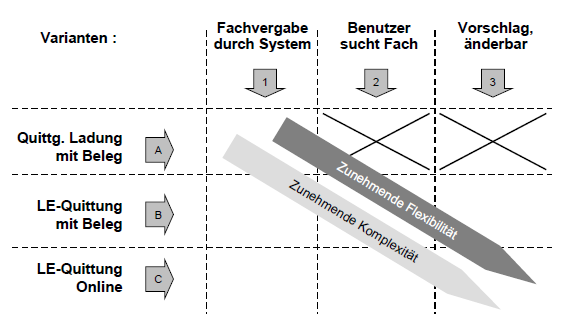

Some types of storage, such as high-bay warehouses or automatic small parts warehouses, have a pre-zone. From there, the goods are picked up and put away. In putaway, the goods are first confirmed at a flat rate, individually or online. The way in which the confirmation is carried out depends on the resources available. For example, whether a warehouse management system, a radio terminal or even an automatic storage and retrieval machine is used in the warehouse. Like the acknowledgement, the type of compartment allocation also varies. It can be triggered by the system, by the user or by a system proposal for the putaway compartment that can be changed by the user.

Allocation of the storage compartment during storage

The allocation of the storage compartment is generally influenced by various aspects, such as:

- Physical requirements of the stored goods

- Safety and legal requirements

- Operational optimisation

The ideal solution is to move the stored goods quickly to an approved storage location because it is not only a question of being effective, but especially efficient. Thus, the storage compartment volume should be used optimally (physical requirement). It is also important to observe prohibitions regarding the combined storage of certain articles and to comply with the maximum permissible shelf space load (safety and legal requirements). By minimising travel and transport distances or by making maximum use of existing storage capacities, the processes in the company can be improved (operational optimisation). The optimal implementation or compliance with these criteria contributes to the fact that the subsequent processes after storage in a storage compartment are not or only minimally restricted.

Putaway – the key figures

By means of corresponding storage key figures, the economic efficiency, as well as the productivity and quality of the storage, can be assessed.

From this process, the number of storages and articles, as well as the number and distance of storage locations, are of importance for the control center.

In order to measure the storage targets, the key figures for the following processes play a role: number of storages, capacity utilisation, storage time, work progress, quality of the storage.

The recipients of the key figures are the logistics manager, the warehouse manager and other employees who play a role in the transportation.

Putaway – the pre-zone

After delivery in the goods receiving area, the goods are either picked up manually or automatically transported to the warehouse via conveyor technology. Some storage types often have a preliminary zone from where the goods are received and put away. If the warehouses are operated automatically, then putaway and material withdrawal are carried out using automatic storage and retrieval machines.

Of the goods to be put away, information such as type of goods, article number, quantity and weight is registered. Digital recording via RFID or barcodes is often used to identify the goods. The data is usually recorded using sensors or scanners. The data is usually collected using sensors or scanners.

Scanning a barcode on the articles ensures exact identification; this is so important because only uniquely identified goods make efficient management possible in the first place. The warehouse management system uses the information read out to determine the optimum storage location and updates the inventory file.

Further information on systemic allocation assignment:

- ABC analysis in stock management

- Occupancy Strategies – overview

- The storage zone and cube-per-order index

The counterpart to the pre-zone is the stock removal area, in which the goods are stored after being removed from storage. From there, the goods are transported to picking or goods issue.

Putaway – acknowledgement and allocation of compartments

For the putaway several types of acknowledgement are available:

A – The blanket confirmation of the putaway for a whole load

It only makes sense if the warehouse management system has previously assigned the subject and is rather an exotic case.

B – The individual confirmation with document

The forklift driver returns the putaway document after the putaway; this document is used for posting. In manual warehouses, the employee confirms the putaway via MDE.

C – The online confirmation at the compartment

It requires that industrial trucks be equipped with radio terminals. Putaway with an automatic storage and retrieval machine is logically equivalent to this case.

In addition, the subject allocation can be solved in different ways:

- The assignment of compartments by the system requires that the system knows all data and decision criteria and that no constellations occur which, for example, cannot be physically implemented (for example, pallet higher/wider than compartment)

- The selection of the storage compartment by the user avoids this problem and thus reduces the requirements profile for data quality (and quantity).

- The combination of the first two variants is formed by a system proposal for the storage compartment that can be changed by the user.

In addition to the core function of searching for a free storage compartment, a modern logistics system can also take over the order of a forklift (see forklift control system).

Goods urgently required in the dispatch department are intercepted via “cross docking” immediately in the goods receiving department and are forwarded directly to the goods issue department, bypassing the actual warehouse. In some cases, if there is an urgent need in picking, a bypass delivery to this area can also be carried out.

Summary of the putaway process in intralogistics

The process steps that are carried out in the course of the putaway include:

- Accept transport request

- Identify articles

- Add article

- Transporting articles

- Place item in the warehouse

Short throughput times, high process quality and flexibility in storage are among the objectives of this business process.

A quality inspection is often carried out between the goods receipt and putaway processes. If the quality meets the correspondingly set standards, the article is released for use and is booked out with a subsequent inspection document. This is followed by labeling and any special processes, such as repacking an article. When an order is accepted, the allocation is usually carried out using mobile data entry (MDE). The destination is then assigned automatically. Scanning a barcodeon the article enables exact identification, whereupon the articles are either picked up manually or automatically transported to the warehouse via conveyor technology. A suitable storage location is identified, the articles are stored in it, and the transfer order is completed. When the putaway is completed, it is possible to clearly assign the article and storage location using article barcodes and shelf barcodes.

From this process, the number of putaways, the number and distance of the storage locations and the number of articles are important for the control centre.

The number of putaways, capacity utilization, putaway time, work progress and the quality of the putaway all play a role in measuring the targets.

Further information:

Warehouse management - as simple as possible, as complex as necessary

Our WMS offers you an individually tailored, lean and process-oriented warehouse management.

Also available in Deutsch (German)