What are you looking for?

16. September 2014

Data Mart: the local warehouse database analysis

Data mart describes the use of a database that is only a department-specific part of the overall data warehouse. For this reason, it is also referred to as the departmental database. Generally, such an extract from the entire database is used to…

8. September 2014

Overview – Serial Shipping Container Code (SSCC)

Each shipping unit, which can be a pallet or a carton, for example, is automatically assigned a "Serial Shipping Container Code" (prev. "Serial Shipping Container Code" (SSCC)). This is a globally unique and unmistakable sequence of digits that…

27. June 2014

Defintion and advantages of consignment

The term consignment refers to a form of delivery of goods in which the supplier acts as consignor and the customer as the consignee. The consignor is the owner of the goods until either an agreed period expires or the consignee removes the goods…

6. June 2014

FEM 9.831 Calculation basis for stacker cranes for high-bay warehouses

FEM 9.831 is a standard for the use of stacker cranes in high-bay warehouses. The standard specifies tolerances, deformations and clearances for stacker cranes in high-bay warehouses. It applies to high-bay warehouses with stacker cranes that…

5. May 2014

Distance selling contract

A distance contract is a contract concluded between an entrepreneur and a consumer by means of distance communication. The means of distance communication include letters, catalogs, telephone calls, faxes, e-mails as well as radio and other media…

24. April 2014

Definition of Same Day Delivery

Same Day Delivery means that inventory is delivered on the same day it was ordered. Ordered today, delivered tomorrow is already a standard with some e-commerce distributors. The next step is same day delivery. Intralogistics requirements for…

19. March 2014

Master data

In intralogistics, master data, also known as primary data or reference data, is data that contains operationally relevant information. This includes information about products, suppliers and customers, for example. Individual data is assigned to an…

11. March 2014

VDI 3601 – Warehouse Management Systems

In Guideline 3601 - "Warehouse Management Systems", the Association of German Engineers (VDI) describes which requirements a Warehouse Management System (WMS) should fulfill. The VDI thus answers a question that has been around for years: When are…

24. February 2014

Batch formation in picking

Batch formation during picking, also known as batch picking or multi-order picking, is a form of two-step picking and is used in picking forms such as series-oriented, parallel picking. Requirements from several individual orders are combined in…

3. February 2014

Storage and retrieval machine

A storage and retrieval machine (SRM) is a storage device with which load units can be stored, transferred and retrieved. The storage, transfer and retrieval performance of a storage system depends on the following factors of the storage equipment…

24. January 2014

The beginnings of logistics

Even before the invention of the wheel, materials were transported, handled and stored. Even then, the effort required especially for the material flow was enormous - initially without any degree of automation. The term intralogisticsis still quite…

20. December 2013

Definition – Value chain

A value chain describes how value is created through a chain of activities and combined in processes. The value chain is also referred to as process chain or performance chain. Establishment of a value chain To analyze a value chain, a company's…

10. December 2013

Sorter (Packing) – Basics

After the picking business process, the product is passed on to the sorter (packing department). However, the sorter and the downstream packing department are only available for two-stage picking. It is not required for single-stage picking, because…

6. December 2013

Lean Management

Lean management also has several sub-categories, such as lean thinking, lean production and lean supply chain. It describes various methods and procedures to optimally plan the processes of the value chain for industrial goods. The goal of this…

4. December 2013

Single-stage picking – basics

During picking, a certain quantity of articles is picked from an assortment and put together. Picking in a warehouse can be single-stage or multi-stage. In single-stage picking, the picker always works on an order-related basis as he moves through…

3. December 2013

Definition – Transshipment logistics

Goods handling is a function of intralogistics and takes place between the external goods flow and the internal material flow. The cargo of a means of transport is loaded onto an internal means of transport or vice versa, i.e. from an internal means…

21. November 2013

Picking – definition and picking methods

Picking stands for the assembly of goods and merchandise according to specified orders from an available overall assortment. Depending on the customer in question, the order can be compiled on an order-related basis or without an order. These…

14. November 2013

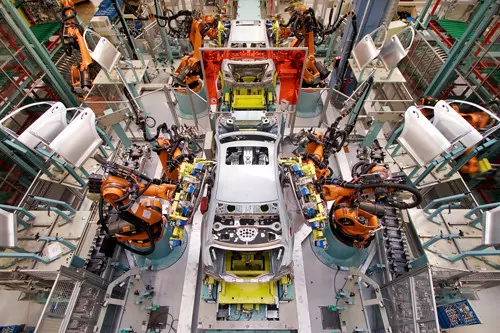

Overview of common manufacturing principles

Different principles can be applied in manufacturing. Some products are manufactured according to forecasts, without specific sales order With other products production only starts after the reception of a sales order. Push and pull systems…

12. November 2013

Push system and pull system in supply chains

Supply chain management refers to the value chain from the supplier to the end consumer. Depending on the direction of the supply chain, there are two systems. The push system and the pull system. A company can trigger the production or delivery of…

30. September 2013

Modernization: retrofit in intralogistics

Term retrofit refers to the modernization of machines and equipment. It includes the terms conversion, renovation, and retrofitting. In intralogistics, retrofit is used to fully exploit the potential of older facilities. Modernizations or…

25. September 2013

Material throughput time

The material throughput time is the time required to run through all business processes, for example, in a warehouse or distribution centre. The calculation of the lead time begins with Goods receipt and ends when the material is made available for…

20. September 2013

Time strategies: throughput and delivery time reduction

Besides the just-in-time and just-in-sequence methods, other time strategies can be used to ensure that materials are in a constant flow. A smooth material flow has a positive effect on throughput and delivery times. Cost reducing time strategies…

17. September 2013

Mobile and stationary loading units

Loading units are collections of goods that are transported, transhipped or stored as they pass through the supply chain. In contrast to stationary units, mobile units can be freely transported, stacked and moved. Mobile loading units Good examples…

16. September 2013

Potential analysis in intralogistics

A potential analysis is a comparison of company performance with the given expectations for said company. In logistics, it is also known as a logistics audit and is used as a future-oriented, strategic planning tool. Processes and structures of the…

16. September 2013

Performance analysis in logistics

A performance analysis examines various service points in logistics for their contribution to value creation. This involves checking at what cost and in what quality the service points of logistics areas, such as procurement, production,…

9. September 2013

Transport strategies: Overview

Transport strategies are used to execute existing transport orders. Transportation strategies can be used for transportation planning to route the transport units to the appropriate destinations. There are four transport strategies: station…

3. September 2013

Continuous conveyor / discontinuous conveyor

Both the continuous conveyor and the discontinuous conveyor belong to the conveyor technology category. Both systems are used to transport goods from one place to another. They differ in that the continuous conveyor generates a constant transport…

30. August 2013

Overview of linear sorter systems

The linear sorter, or shoe sorter, is an automated sorting and distribution system on which the goods are transported and distributed to their designated stations by a sliding mechanism. This sorting and distribution method is a continuous material…

2. August 2013

Electronic Product Code (EPC)

The electronic product code EPC is an international product identification. Each product can thus be identified worldwide and it is intended to replace the European Article Number (EAN). The EPC is stored in an RFID transponder. The code is…

17. July 2013

Decision making for discontinuous conveyors

In a transport system that does not convey continuously, the decision as to whether a transport object can be transferred from one location to another is made directly in the control system. In the first step, this depends solely on the physical…

2. February 2016

Automated guided vehicles (AGVs)

From the technical committee of the VDI (Association of German Engineers), automated guided…

28. January 2016

Cut-off time in intralogistics

In intralogistics, the cut-off time describes the time at which an order must leave the warehouse…

26. January 2016

The Newsvendor Model in SCM

Many supply chain management (SCM) approaches can be explained using the Newsvendor Model (NVM).…

18. January 2016

Function and advantages of the ant algorithm

The Ant Algorithm, also often called Ant Colony Optimization (ACO) in the literature, is an…

15. January 2016

The cost of unused opportunities in supply chain management

No company can afford not to have the cost side under control. The figures from financial…

14. December 2015

Ship to Line / the direct provision of goods

In the case of ship to line or direct provision of inventory, the supplier/manufacturer assembles…

7. December 2015

Definition – The Milk Run Concept

The milk run concept is a method for optimizing inter-company procurement logistics, often used in…

1. December 2015

The degree of utilisation/the capacity utilisation

The degree of capacity utilisation describes the proportion of the capacity used by…

2. November 2015

Definition of Accounting / Bookkeeping

The term accounting describes the comprehensive recording, storage and analysis or evaluation of…

19. October 2015

Buffer line

A buffer section is used to intercept jams within the material flow, to avoid bottlenecks and idle…

21. September 2015

Information in intralogistics

Information describes the meaningful content of a message, which is of value for the recipient. The…

18. September 2015

Returns processing

Returns handling describes several processes in the return of goodsordered - mostly - online. They…

14. September 2015

Storage capacity/storage economy

Storage capacity is defined as the maximum number of loading units that a warehouse can hold. It…

26. August 2015

Host system (ERP system)

The host system (usually an ERP system) is a central data processing system that can be accessed…

31. July 2015

Definition of order processing in intralogistics

Order processing includes all formal processes such as order transmission, data processing and…

22. July 2015

Heijunka lean method

The Japanese lean method Heijunka pushes a production where the production flow of the parts market…

10. July 2015

Assortment width and assortment depth

The assortment available in a warehouse and in the retail trade is subdivided into the assortment…

6. July 2015

Modularization of materials handling equipment – approach to a standardized system architecture

The current market development shows the following challenges: New component technologies require…

17. April 2015

Lean Production

Lean Production describes a method with the goal to react quickly to outside influences on…

14. April 2015

The distribution center

A distribution center is an interface in the form of a building complex that functions exclusively…

6. March 2015

Order throughput time

When an order is received in a logistics centre, it passes through various processes until it is…

23. February 2015

The barcode – EAN, GTIN and GS1 standard

Barcodes have successfully established themselves over other systems in recent years. The barcode…

8. January 2015

Temperature-controlled logistics (environmental measurement)

The market for temperature-controlled logistics in particular has been growing in volume over the…

2. December 2014

Overview and definition of ident carriers

In order to be able to identify an object without any doubt throughout the entire logistics chain,…

10. October 2014

Production management

According to business economist Werner Kern, production management is an operational service…

Also available in Deutsch (German)